The first of the massive fuel tanks that will fly on the maiden launch of NASA’s SLS mega rocket in late 2018 has completed welding at the agency’s rocket manufacturing facility in New Orleans – marking a giant step forward for NASA’s goal of sending astronauts on a ‘Journey to Mars’ in the 2030s.

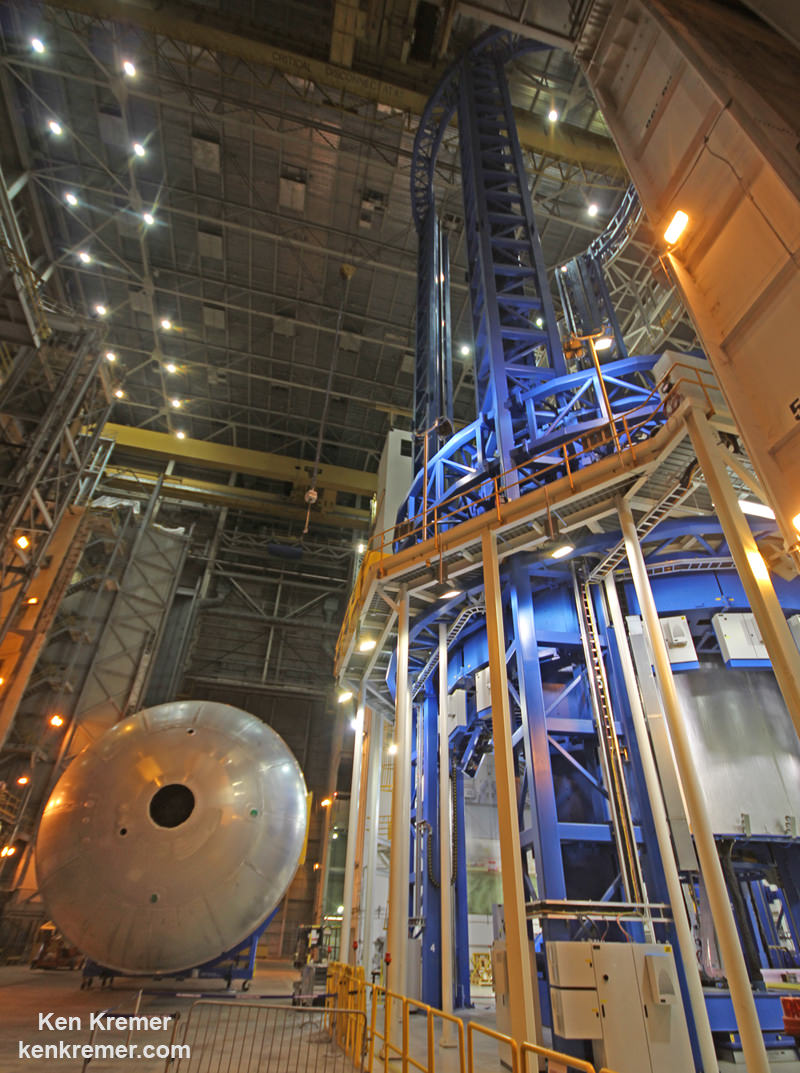

Technicians have just finished welding together the liquid hydrogen (LH2) fuel tank in the Vertical Assembly Center (VAC) welder at NASA’s Michoud Assembly Facility (MAF) in New Orleans. The VAC is the world’s largest welder.

This flight version of the hydrogen tank is the largest of the two fuel tanks making up the SLS core stage – the other being the liquid oxygen tank (LOX).

In fact the 130 foot tall hydrogen tank is the biggest cryogenic tank ever built for flight.

“Standing more than 130 feet tall, the liquid hydrogen tank is the largest cryogenic fuel tank for a rocket in the world,” according to NASA.

And it is truly huge – measuring also 27.6 feet (8.4 m) in diameter.

I recently visited MAF to see this giant tank when it was nearly finished welding in the VAC. I also saw the very first completed test tank version of the hydrogen tank, called the qualification tank which is virtually identical.

The precursor qualification tank was constructed to prove out all the manufacturing techniques and welding tools being utilized at Michoud.

SLS is the most powerful booster the world has even seen and one day soon will propel NASA astronauts in the agency’s Orion crew capsule on exciting missions of exploration to deep space destinations including the Moon, Asteroids and Mars – venturing further out than humans ever have before!

NASA’s agency wide goal is to send humans to Mars by the 2030s with SLS and Orion.

The LH2 and LOX tanks sit on top of one another inside the SLS outer skin. Together the hold over 733,000 gallons of propellant.

The SLS core stage – or first stage – is mostly comprised of the liquid hydrogen and liquid oxygen cryogenic fuel storage tanks which store the rocket propellants at super chilled temperatures. Boeing is the prime contractor for the SLS core stage.

The SLS core stage stands some 212 feet tall.

The SLS core stage is comprised of five major structures: the forward skirt, the liquid oxygen tank (LOX), the intertank, the liquid hydrogen tank (LH2) and the engine section.

The LH2 and LOX tanks feed the cryogenic propellants into the first stage engine propulsion section which is powered by a quartet of RS-25 engines – modified space shuttle main engines (SSMEs) – and a pair of enhanced five segment solid rocket boosters (SRBs) also derived from the shuttles four segment boosters.

The vehicle’s four RS-25 engines will produce a total of 2 million pounds of thrust.

The tanks are assembled by joining previously manufactured dome, ring and barrel components together in the Vertical Assembly Center by a process known as friction stir welding. The rings connect and provide stiffness between the domes and barrels.

The LH2 tank is the largest major part of the SLS core stage. It holds 537,000 gallons of super chilled liquid hydrogen. It is comprised of 5 barrels, 2 domes, and 2 rings.

The LOX tank holds 196,000 pounds of liquid oxygen. It is assembled from 2 barrels, 2 domes, and 2 rings and measures over 50 feet long.

The maiden test flight of the SLS/Orion is targeted for no later than November 2018 and will be configured in its initial 70-metric-ton (77-ton) Block 1 configuration with a liftoff thrust of 8.4 million pounds – more powerful than NASA’s Saturn V moon landing rocket.

Although the SLS-1 flight in 2018 will be uncrewed, NASA plans to launch astronauts on the SLS-2/EM-2 mission slated for the 2021 to 2023 timeframe.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.