In this decade, multiple space agencies will send astronauts to the Moon for the first time since the Apollo Era. In addition to NASA, the ESA, China, and Roscosmos, commercial space entities like SpaceX and Blue Origin are hoping to conduct regular missions in support of human exploration while also mounting their own private ventures. In time, this activity could result in the creation of permanent infrastructure, a regular human presence, and the emergence of a lunar economy. Nevertheless, there are many questions about how humans will live in lunar conditions and what type of facilities will be needed.

To this end, the Austrian-based inflatable structures specialist Pneumocell recently conducted a study to determine if lightweight prefabricated structures would be a suitable option. According to this study, a series of donut-shaped inflatable structures could be transported to the Moon at a low cost, where they would then be inflated. The habitats would be partially buried beneath the lunar regolith and surrounded by solar mirrors that could direct sunlight into their greenhouses. This “Inflatable Moon Habitat” offers a cost-effective and highly self-sufficient means of establishing a foothold on the Moon.

The study was led by Pneumocell CEO Thomas Herzig, an Austrian architect who specializes in the design of self-sufficient habitats for extreme environments. He was joined by Gabor Bihari (an experimental physicist with the University of Debrecen, Hungary) and Dr. Norbert Kömle, a researcher with the Austrian Academy of Sciences (OeAW). The study was conducted in 2021-2022 after Pneumocell submitted its idea for an “Inflatable Moon Habitat” to the European Space Agency’s (ESA) Open Space Innovation Platform (OSIP).

The study was conducted with the support of the ESA’s Discovery and Preparation program, which conducts design feasibility studies of new mission concepts and helps formulate ESA exploration strategy. The goal of the study was to develop a design for a lunar habitat that could leverage lunar resources – known as In-Situ Resource Utilization (ISRU) – and achieve self-sufficiency. The concept comes down to three main steps, which would consist of:

- Prefabricated ultralight inflatable structures.

- Covering the structures with a layer of regolith for efficient protection against extreme temperatures, meteorites, and cosmic radiation.

- The use of “sunflower” mirrors that direct sunlight into the greenhouses. During dark periods, power is provided by batteries and/or fuel cells.

The prefabricated structures would be transported to the lunar landing site, where they would be inflated and covered in 4 to 5 meters (~13-16.5 feet) of loose regolith. Above each habitat, a truss would be erected to hold a mirror membrane designed to follow the Sun through the sky. The mirrors themselves are composed of silver-coated Kapton, a polyimide film capable of withstanding extreme temperature and vibration. These direct sunlight downwards into the habitat, where a cone-shaped mirror reflects it into the surrounding greenhouse.

Getting There

The lightweight and module structure of the prefabricated structures makes them very cost-effective for transporting to the Moon. From this, Herzig and his colleagues included an analysis of possible transportation methods (based on existing or planned spacecraft) for both the modules and astronauts. While they indicate that the SpaceX Starship would be able to transport all the necessary components to the Moon, launch services could also be provided by smaller rockets like the Ariane-64, a modified version of the Ariane 6 that has four solid rocket boosters.

This would be paired with the European Large Logistics Lander (EL3), a planned vehicle intended to fulfill multiple types of proposed ESA missions to the Moon. They also indicate that the Lunar Gateway is not needed to realize the Inflatable Moon Habitat, though it could be part of the mission. At present, NASA plans to send the core elements of the Gateway – the Power and Propulsion Element (PPE) and the Habitat and Logistics Outpost (HALO) – to the Moon by 2024 and has contracted SpaceX to provide the launch services with a Falcon Heavy rocket.

Site Selection

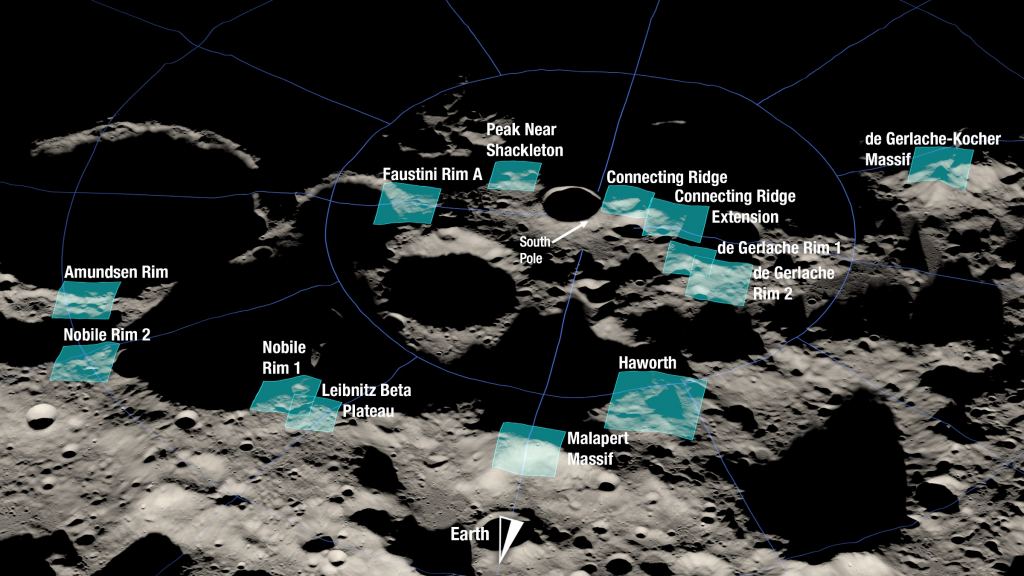

But of course, site selection must take place before any missions are launched; hence why Herzig and his colleagues considered the best possible sites around the lunar poles as a first step. This was done using data from NASA’s Lunar Reconnaissance Orbiter (LRO) and illuminations models based on previous geological studies of the Moon (Glaser et al. 2015, 2018). They identified that the two best locations were the C1 “Connecting Ridge” between the Shackleton and de Gerlache craters near the south pole and the H0 area near the rim of the Hinshelwood crater near the north pole.

These sites offer optimal lighting conditions and are close to the Permanently Shadowed Regions (PSRs) or crater floors that provide access to abundant near-surface water ice. This is consistent with the list of the thirteen potential landing sites recently identified by NASA for the Artemis III mission (which included the rim of the Shackleton Crater and was based on LRO data). However, Herzig and his colleagues indicated that the terrain might be too steep and rugged, and there could be a possible mechanical instability in the ground.

The team also evaluated these sites based on their access to solar irradiation, creating an illumination profile at the surface and the height of the solar mirrors – 10 and 20 meters (33 and 65.6 feet). They calculated that the longest period of uninterrupted total darkness is eleven days at the north polar H0 site, while the south polar C1 site experiences only four days. Between these two considerations, the northern polar site appears more structurally sound, while the southern site offers better opportunities for better illumination.

The Habitats

Each habitat consists of room modules that can be connected with others to extend the habitat and increase the total volume for the crew. Regarding building materials, the team investigated several possibilities and recommended using carbon-fiber-reinforced polymers (CFRPs). They specifically recommend thermoplastic polyurethane (TPU) or Mylar for the habitat walls and Dyneema (a composite of polyethylene laminated between two sheets of polyester) to make the tubes that support the mirror.

The main modules are toroidal (donut-shaped) greenhouses that have corridors measuring 5.2 m (17 ft) in diameter and a total diameter of 22.2 m (72.8 ft). These greenhouses are connected via a tunnel system with additional modules (living and working areas) attached to their outer sides. The team recommended starting with one greenhouse and adding additional modules over time to achieve the following architecture:

“[W]e suggest a “village” consisting of 16 greenhouse units that are placed in a double linear arrangement in order to minimize mutual shadow casting among the mirror towers when the Sun moves along the lunar horizon. Greenhouses, living areas, and connecting tunnels are all made of double-layered inflatable foils, while the towers carrying the upper mirrors are a low-weight construction consisting of carbon fiber tubes. Moreover, a redundancy of the corridors keeps the parts connected even if some parts are destroyed in an accident.”

To save weight, all the mirrors are made of silver-coated foils that are bent into the correct shape by electrostatic charging. This takes advantage of a key characteristic of lunar regolith, which is its charged nature that causes it to stick to everything (and presents a major hazard to machinery and astronaut health). The upper mirrors are positioned at an angle to reflect the nearly-horizontal sunlight into the geometric center of the torus. From there, it is reflected via the conical mirror into the greenhouse through a window consisting of two transparent foils.

This system of mirrors will be able to provide about 65 kilowatts (kW) during a lunar day. As they note, this is necessary for food production but could lead to thermal problems:

“While this power is necessary to optimally facilitate photosynthesis, it would quickly overheat the greenhouse without an active cooling radiator. In our design, the cooling system operates with ammonia and water as working fluids. In this way, the temperature inside the greenhouse can be kept close to 26°C during the illumination phases. During dark periods, the active cooling is switched off and mirrored roller blinds cover the window in order to limit heat losses to a minimum.”

Next, they considered the habitat’s life support system and food production and how these could be part of a recycling system that meets all the astronauts’ needs. For the atmospheric requirements, they concluded that a mixture of 35% oxygen, 64% nitrogen, and 1% carbon dioxide (CO2) at a pressure of 0.5 bar would be ideal for the greenhouses. This is slightly different from Earth’s, which consists of 23% oxygen, 75.5% nitrogen, and 0.06% of carbon dioxide by mass, and where the air pressure is 101.325 kilopascals (1.01325 bar) at sea level.

The entire system is driven by solar power and is cyclical, where the greenhouse plants metabolize CO2 via photosynthesis, and oxygen gas is created as a by-product. This not only replenishes the oxygen supply for the crew but prevents a build-up of CO2 from astronaut exhalation. Meanwhile, non-edible plant waste and excrement are composted to create natural fertilizer to help maintain soil health. During dark periods, excess CO2 is temporarily stored in a cryogenic container and reintroduced during periods of daylight. As Herzig and his colleagues note, this creates a closed-loop bioregerative system:

“Altogether, it appears possible to create in the long term a closed system, in which each greenhouse unit produces enough food to nourish a crew of two humans without the need to import additional food from earth. Generally, we create [on] a small scale a complete sustainable ecological cycle as we (should) have on Earth.”

Cost/Benefit Compared to Other Habitats

As the last step, the team evaluated and compared their proposal with two other recently developed (and ESA-supported) lunar habitat designs. These include the Lunar Outpost by Foster and Partners, proposed in 2012, and the more recent Moon Village by SOM Architects, unveiled in 2019. These two designs offer a good representation of the elements considered for space habitats. Whereas the Lunar Outpost consists of an inflatable structure covered by a 3D-printed shell (using regolith and polymers), the Moon Village calls for prefabricated rigid and partly inflatable structures.

Both of these elements are used in the PneumoPlanet habitat in a way that combines their benefits while offering the greatest cost-effectiveness. As Herzig and his team summarize:

“[O]ur PneumoPlanet design features by far the lowest payload per m2 of usable area, the most effective protection from cosmic particle radiation, and the lowest energy requirement for the construction process and in operation. Additionally, it is the only concept of all published until now, that provides a complete ecological cycle for self-sufficient production of food and oxygen.”

In short, the Inflatable Moon Habitat combines the benefits of low transportation costs, inflatable modules, ISRU, and a close-loop system to ensure safe and sustainable living on the Moon. Herzig and his colleagues conclude by stating that a prototype should be built on Earth that could be used to investigate various details and the components of the design. They specifically recommend that the performance of the electrostatic mirror foils, the life cycle inside the greenhouses, the material properties of the inflatable foils, and/or the transparent foil be the subject of investigation.

These and other design studies are part of the ESA’s long-term vision for lunar exploration. Alongside NASA, other space agencies, and commercial partners, the ESA hopes to create the infrastructure that will allow for a sustained human presence on the Moon. In particular, they have expressed the desire to create an International Moon Village where astronauts of many nationalities can work together and conduct science operations in lunar gravity. The idea was first announced in 2015 by Jan Wörner, the then-Director General of the ESA, who described the idea in an interview with Euronews.

“My intention is to build up a permanent base station on the Moon,” he said. “Meaning that it’s an open station, for different member states, for different states around the globe.”

In 2016, he described the concept further during a speech titled “A vision for global cooperation and Space 4.0,” which he delivered during the 2016 Ministerial Council Meeting (CM16) in Lucerne, Switzerland. As he stated:

“The paradigm shift that we see today in space activities is best encapsulated by the term ‘Space 4.0,’ and the ‘Moon Village’ concept seeks to transform this paradigm shift into a set of concrete actions and create an environment where both international cooperation and the commercialization of space can thrive.

“The Moon Village concept was developed through a process of thorough analysis, but it is vital to understand that what we are describing is neither a project nor a program. By ‘Moon Village,’ we do not mean a development planned around houses, some shops, and a community center. Rather, the term ‘village’ in this context refers [to] this: a community created when groups join forces without first sorting out every detail, instead simply coming together with a view to sharing interests and capabilities.

This “Village” is the goal that proposals like the Inflatable Moon Habitat will help enable. By establishing a temporary human presence on the Moon using prefabricated, easy-to-deploy structures, astronaut crews and robotic workers can oversee the creation of a permanent lunar base. This will enable a new era of lunar exploration and research built on international cooperation, mutual assistance, and lucrative partnerships between government and industry.

To learn more about the ESA’s research and development programs, check out the Nebula Public Library. Head over to Pneumocell’s website for additional information, pictures, and videos of the Inflatable Lunar Base and other concepts by Thomas Herzig – like the Pneumo Planet Mars Habitat (which inspired the design of their Inflatable Lunar Base). Also, here’s a study by Bihari and Herzig for another Mars habitat known as “Space Nomad.”

Further Reading: ESA