What sounds like a slap-stick comedy shtick is actually solid science. With so much of humanity’s space-faring future involving habitats, other structures, and a permanent presence on the Moon and Mars, mixing concrete in space is serious business. NASA has a program of study called MICS, (Microgravity Investigation of Cement Solidification) which is examining how we might build habitats or other structures in microgravity.

Concrete is the most widely-used material on Earth, not counting water. It’s more widely-used than wood. It’s also been around for a long time.

Aside from its insulative quality, concrete can also provide protection from radiation, and its structural strength provides protection from meteorite impacts. Though it’s not the only option for building structures, it will likely have a role to play. It could end up being an important material because only the cement itself, not the aggregrate or the water, needs to be transported.

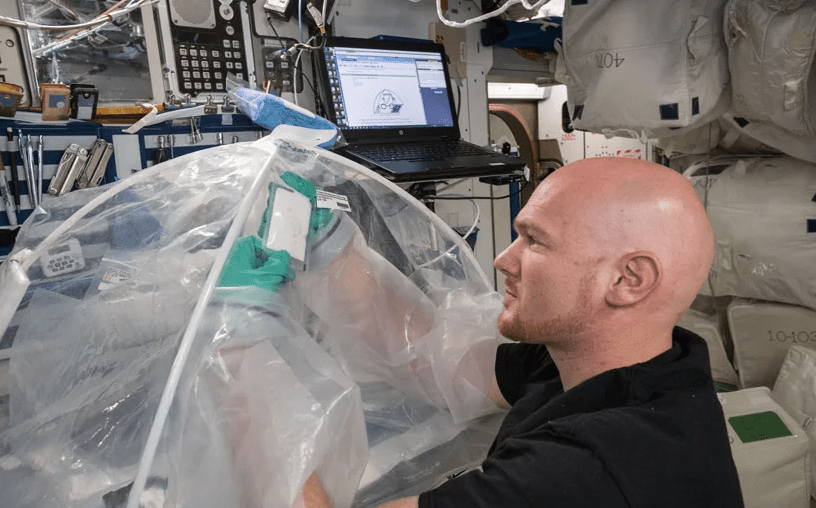

As part of MICS, and a related study called MVP Cell-05, NASA and Pennsylvania State University teamed up with astronauts on the ISS to mix concrete. Concrete’s properties on Earth are well-understood, but microgravity presents another set of circumstances. The results are published in Frontiers in Materials, and is titled, “Microgravity Effect on Microstructural Development of Tri-calcium Silicate (C3S) Paste.”

“Our experiments are focused on the cement paste that holds the concrete together.”

Aleksandra Radlinska, Principal Investigator for MICS.

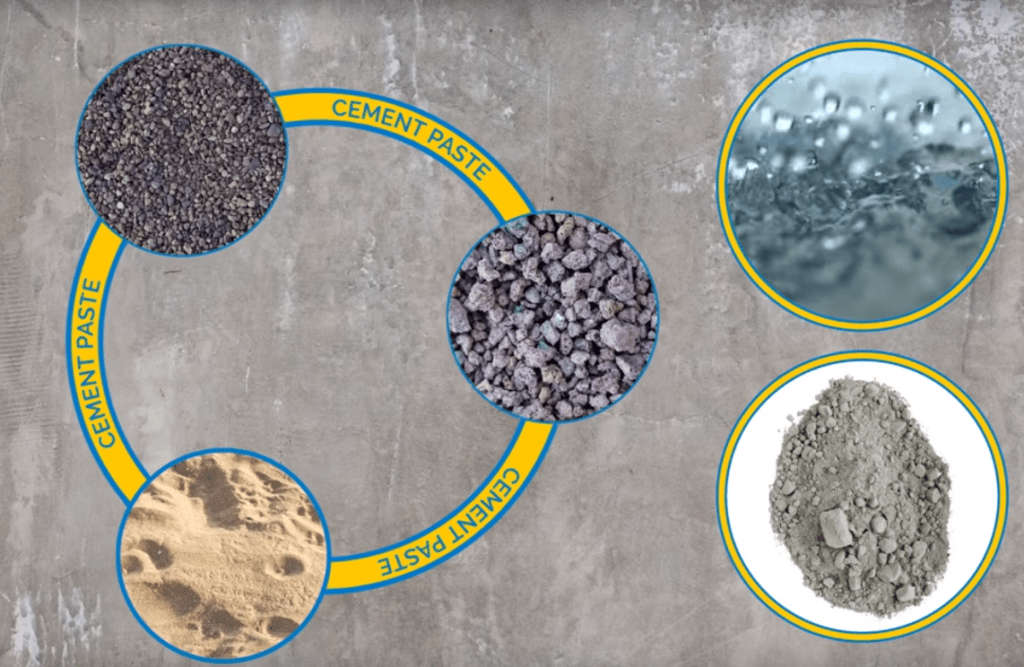

Concrete itself is a mixture an aggregrate, which consists of sand, gravel, and rocks, held together with cement, which comes in two types: Portland cement or geopolymer cement. Combine it all with water, in the right proportions, mix it, and shape it, and when it cures or hardens properly, it’s an extremely strong substance. That’s why some ancient structures like the Roman aqueducts, which were made partly with concrete, still stand.

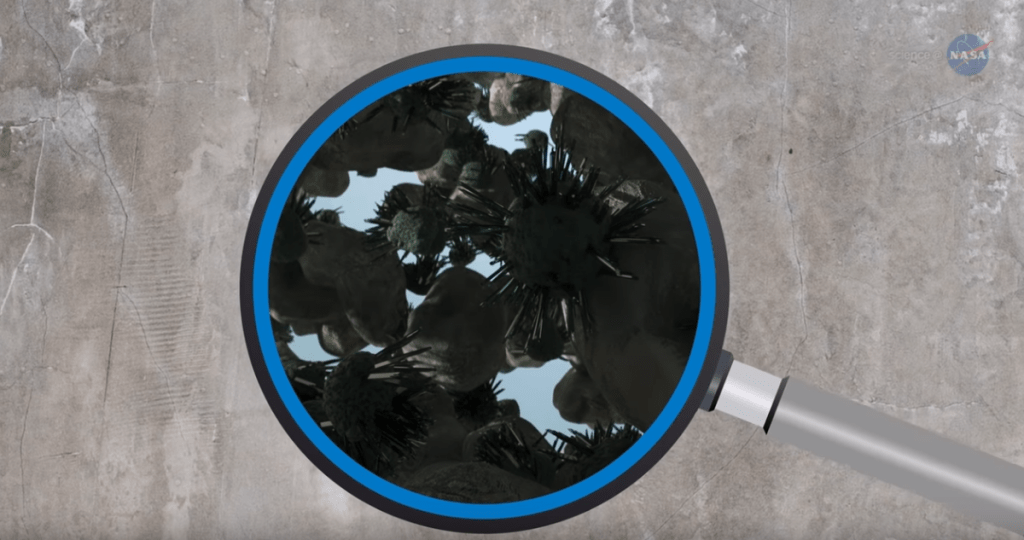

Despite how ubiquitous it is in our modern world, there’s still a lot scientists don’t know about how it works. But they do know that as it hardens, it forms crystals that interlock with each other, and with the sand and gravel, giving concrete its strength. Scientists wanted to know more about how that happens in microgravity.

“Our experiments are focused on the cement paste that holds the concrete together. We want to know what grows inside cement-based concrete when there is no gravity-driven phenomena, such as sedimentation,” said Aleksandra Radlinska, Principal Investigator for MICS and MVP Cell-05.

Regarding the microgravity, Radlinska said, “It could change the distribution of the crystalline micro-structure, and ultimately the material properties.”

“What we find could lead to improvements in concrete both in space and on Earth,” added Rudlinska. “Since cement is used extensively around the world, even a small improvement could have a tremendous impact.”

The ratios of water, aggregrate, and concrete needed to produce concrete with specific properties are well-understood here on Earth. But what about on the Moon? It has only 1/6th Earth’s gravity. Or Mars, which has just over 1/3rd of Earth’s gravity. The experiments were designed to shed light on this question.

In the MICS experiment, the astronauts had a number of packets of cement powder, which they added water to. Then they added alcohol to some of the packets at different times, to stop the hydration.

In the second experiment, MVP Cell-05, astronauts also added water to packets of cement, but they used a centrifuge on the ISS to simulate different gravities, including Martian and Lunar gravities. The samples from both experiments were returned to Earth to be analyzed.

Co-Principal Investigator for MVP Cell-05 is Richard Grugel. He said, “We’re already seeing and documenting unexpected results.”

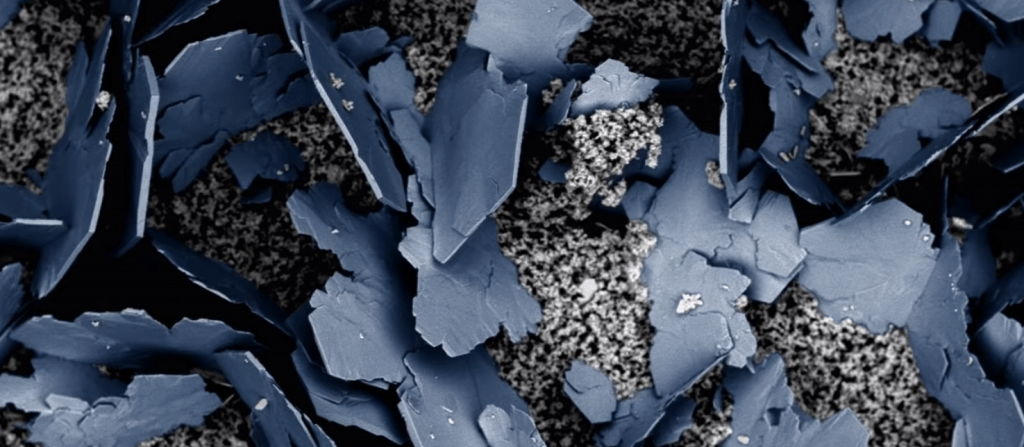

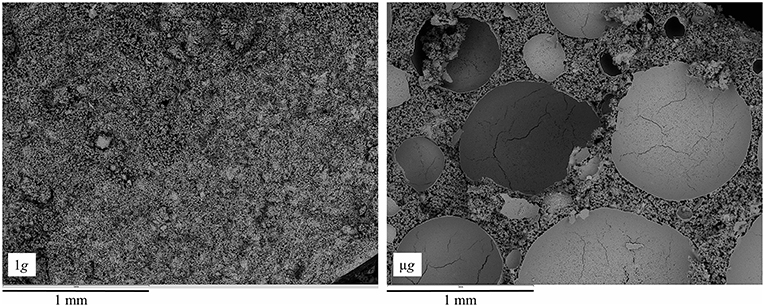

The experimentation showed that concrete mixed in micro-gravity had increased micro-porosity. There were air bubbles in the micro-gravity samples which are not present in Earth gravity samples. That’s because of buoyancy. On Earth, the air bubbles would rise to the top, and in fact concrete is sometimes mechanically vibrated before curing just to help drive out air bubbles, which can weaken the concrete.

Both MICS and MVP Cell-05 samples showed greater crystallization than ground samples. The 20% greater microporosity in the microgravity samples allowed more room for crystallization, and larger crystals, which should create more strength. But the greater microporosity in the microgravity samples also creates less dense concrete, which could mean weaker concrete. The size of the micropores in the microgravity samples was also one order of magnitude larger than ground samples.

The microgravity concrete had less sedimentation, meaning that small particles of aggregate didn’t settle to the bottom during hardening, but are spread more uniformly through the concrete. That means the concrete is more uniform, which could affect strength.

This is an initial study into concrete in microgravity. No strength tests were done on the very small samples, so any conclusions on strength are premature. But it does point out some very different properties between 1G concrete and microgravity concrete, which will no doubt be explored in the future.

“Increased porosity has direct bearing on the strength of the material, but we have yet to measure the strength of the space-formed material,’ said Radlinska in an interview with designboom.

More:

- Study: Microgravity Effect on Microstructural Development of Tri-calcium Silicate (C3S) Paste

- NASA Sciencecast: Cementing Our Place in Space

- Study: Hydration products of C3A, C3S and Portland cement in the presence of CaCO3

- designboom: NASA astronauts explore what happens to concrete when it’s mixed in space

- Portland Cement Association: Cement and Concrete

- National Space Society: Concrete: Potential Material for Space Station