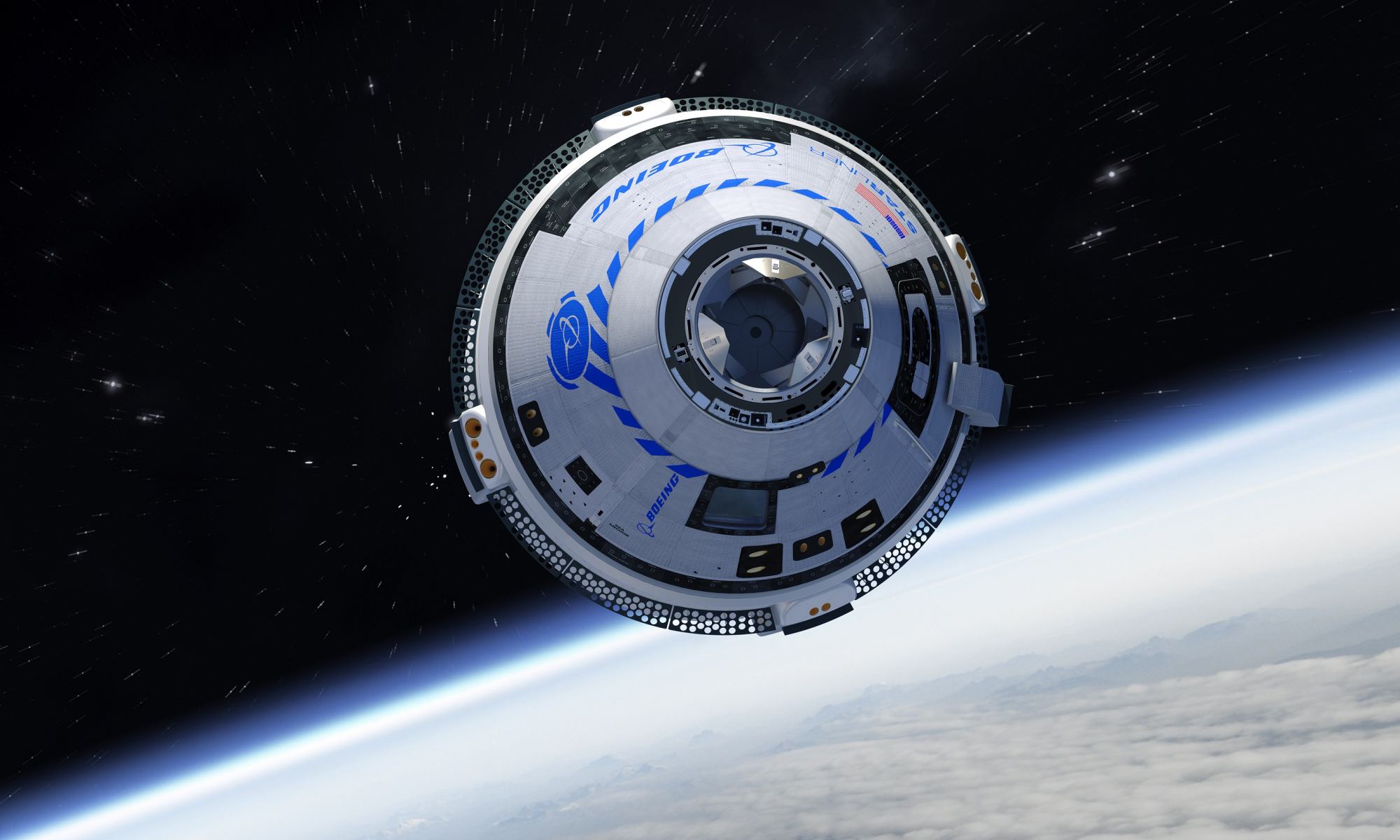

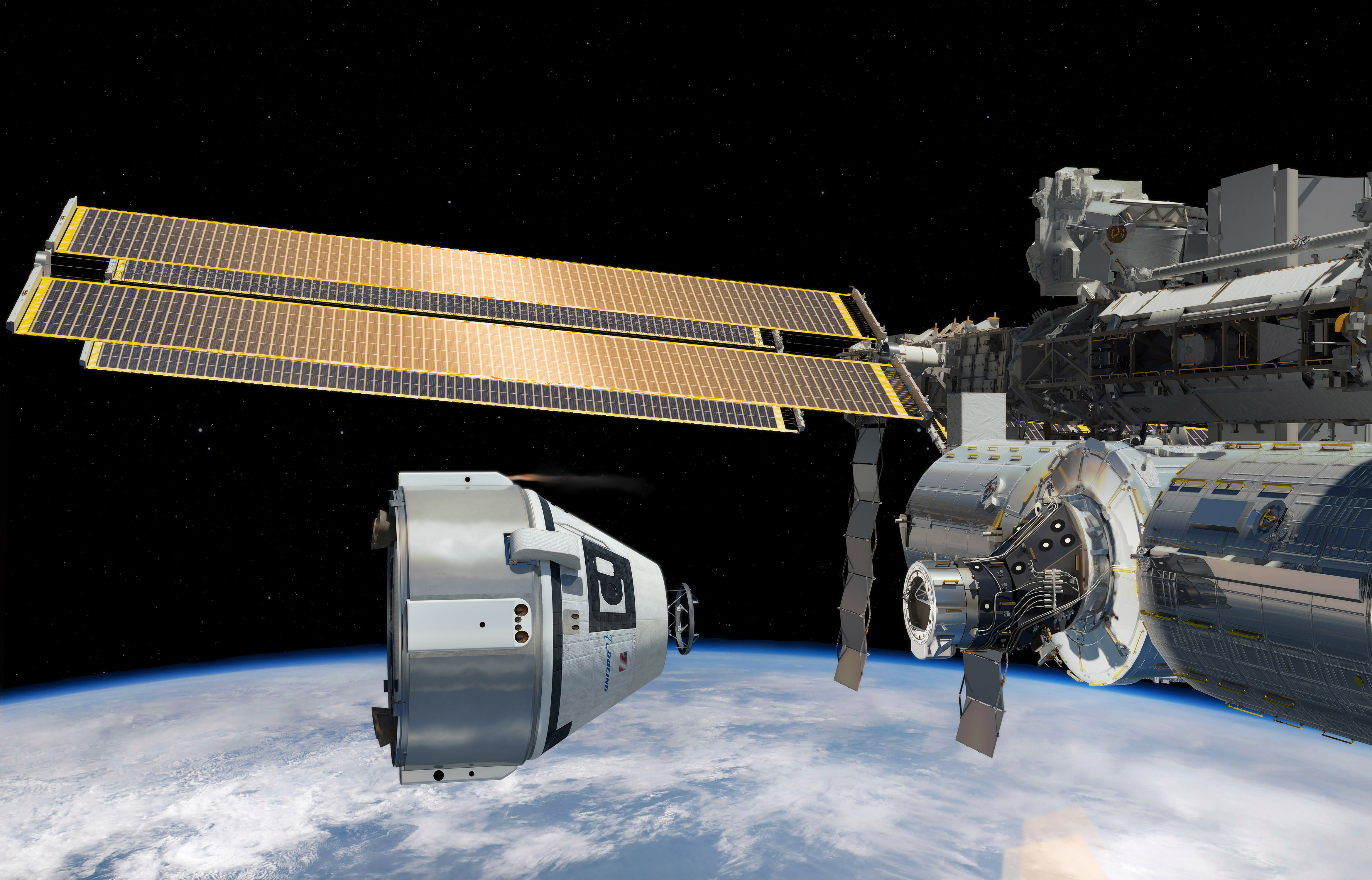

After many delays and two scrubbed launch attempts, Boeing’s CST-100 Starliner successfully launched earlier today! The Crewed Flight Test (CFT) took off from Space Launch Complex-41 at Cape Canaveral Space Force Station, Florida, at 10:52 a.m. EDT (07:52 PDT) atop a ULA Atlas V rocket. For this mission, the capsule is carrying two NASA astronauts: Barry “Butch” Wilmore (commander) and Sunita “Suni” Williams (pilot). They are expected to reach the International Space Station (ISS) at 12:15 p.m. EDT (09:15 a.m. PDT) on Thursday, June 6th.

Continue reading “Starliner Finally Launches, Carrying Two Astronauts Into Orbit”Russia’s new Module Kicks the Station out of Position, Causes a Delay for Starliner

On July 28th, the International Space Station (ISS) suffered a mishap after a new Russian module (named Nauka) fired its thrusters just hours after arriving. As a result, the entire station was temporarily pushed out of position, forcibly delaying the Orbital Flight Test-2 (OFT-2) mission. This would have been Boeing’s CT-100 Starliner’s second attempt to rendezvous with the ISS as part of NASA’s Commercial Crew Program (CCP).

The ISS managed to correct its orbit shortly thereafter, while the OFT-2 launch was delayed until the next available opportunity (Wednesday, Aug. 4th). Unfortunately, the mission was delayed again due to an issue with one of the valves on the spacecraft’s propulsion system. This prompted the ground crews to move the Starliner and Atlas V launch vehicle back into Vertical Integration Facility (VIF), so they can look for the source of the problem more closely.

Continue reading “Russia’s new Module Kicks the Station out of Position, Causes a Delay for Starliner”NASA has a Pretty Big Checklist for Boeing to Fix on Starliner

In 2014, NASA contracted two major aerospace companies (Boeing and SpaceX) to help them restore domestic launch capability to the United States. As part of the Commercial Crew Program (CCE), Boeing and SpaceX developed the CST-100 Starliner the Crew Dragon spacecraft, respectively. But whereas the Crew Dragon finished testing and even carried astronauts to the ISS, the Starliner met with some problems.

During its first uncrewed test flight – Orbital Flight Test-1 (OFT-1) – in December 2019, the Starliner experienced some failures that prevented it from docking with the ISS. After a thorough investigation, the joint NASA-Boeing Independent Review team has completed its final assessment and identified 80 areas where corrections need to be made before the Starliner can conduct another orbital flight test.

Continue reading “NASA has a Pretty Big Checklist for Boeing to Fix on Starliner”NASA tells Boeing to Make 61 Corrective Actions to Starliner Before the Program can Continue

With the retirement of the Space Shuttle in 2011, NASA has become dependent on its Russian counterparts to send and return astronauts to the International Space Station (ISS). Hoping to restore domestic launch capability to American soil, NASA has contracted with aerospace developers like SpaceX and Boeing to develop crew-capable spacecraft, as part of their Commercial Crew Program (CCP).

After years of development, Boeing managed to get their CST-100 Starliner ready for its first uncrewed test flight on December 20th, 2019. Unfortunately, a hiccup occurred during the mission that prevented the spacecraft docking with the ISS. After an independent review of the mission, NASA and Boeing have determined that 61 corrective actions need to be taken before the Starliner can fly again.

Continue reading “NASA tells Boeing to Make 61 Corrective Actions to Starliner Before the Program can Continue”Finally! We get to See a View From Inside Boeing’s Starliner During its First Flight

In 2014, Boeing was awarded a contract through NASA’s Commercial Crew Development (CCDev) program to provide commercial launch services to the International Space Station (ISS). To this end, they have been busy developing the CST-100 Starliner, a space capsule that will be able to deliver cargo and crews of up to 7 astronauts to the ISS. On December 20th, 2019, the Starliner passed a major milestone when it conducted an uncrewed test.

While an error prevented this Starliner (designated Calypso) from docking with the ISS as planned, the space capsule still managed to make it to space and land safely near White Sands, New Mexico. This makes it the first crew capsule to touchdown on land in the United States. To celebrate this accomplishment, Boeing recently released a highlight reel of footage taken by cameras inside the Calypso during the flight test.

Continue reading “Finally! We get to See a View From Inside Boeing’s Starliner During its First Flight”Boeing’s Starliner Performed its Abort Test Today. One Parachute Failed to Deploy

For years, NASA has been working to restore domestic launch capability to the US and send astronauts to the Moon and beyond. A crucial part of this is the development of next-generation crew capsules that can carry crews and payloads to space. These include Lockheed Martin’s Orion Multi-Purpose Crew Vehicle (MPCV) and the Crew Space Transportation (CST) -100 Starliner currently being developed by Boeing.

Earlier today (on Monday, Nov. 4th), the CST-100 passed a critical milestone with a successful end-to-end test of its abort system. The Pad Abort Test took place at Launch Complex 32 at the US Army’s White Sands Missile Range in New Mexico. When crewed missions to space begin using the CST-100, this system will ensure that astronauts will be carried to safety in the unlikely event of an emergency before liftoff.

Continue reading “Boeing’s Starliner Performed its Abort Test Today. One Parachute Failed to Deploy”Boeing Unveils Blue Spacesuits for Starliner Crew Capsule

Boeing has unveiled the advanced new lightweight spacesuits that astronauts will sport as passengers aboard the company’s CST-100 Starliner space taxi during commercial taxi journey’s to and from and the International Space Station (ISS) and other low Earth orbit destinations.

The signature ‘Boeing Blue’ spacesuits will be much lighter, as well as more flexible and comfortable compared to earlier generations of spacesuits worn by America’s astronauts over more than five decades of human spaceflight, starting with the Mercury capsule to the latest gear worn by Space Shuttle astronauts.

“The suit capitalizes on historical designs, meets NASA requirements for safety and functionality, and introduces cutting-edge innovations,” say NASA officials.

The suits protect the astronauts during both launch and reentry into the Earth’s atmosphere during the return home.

Indeed, Chris Ferguson, a former NASA Space Shuttle Commander who now works for Boeing as a Starliner program director, helped reveal the ‘Boeing Blue’ spacesuits during a Facebook live event, where he modeled the new suit.

“We slogged through some of the real engineering challenges and now we are getting to the point where those challenges are largely behind us and it’s time to get on to the rubber meeting the road,” Ferguson said.

The suits offer superior functionality, comfort and protection for astronauts who will don them when crewed Starliner flights to the space station begin as soon as next year.

At roughly half the weight (about 10 pounds vs. 20 pounds) compared to the launch-and-entry suits worn by space shuttle astronauts, crews look forward to wearing the ‘Boeing Blue’ suits.

“Spacesuits have come in different sizes and shapes and designs, and I think this fits the Boeing model, fits the Boeing vehicle,” said Chris Ferguson.

Among the advances cited are:

• Lighter and more flexible through use of advanced materials and new joint patterns

• Helmet and visor incorporated into the suit instead of detachable. The suit’s hood-like soft helmet sports a wide polycarbonate visor to give Starliner passengers better peripheral vision throughout their ride to and from space.

• A communications headset within the helmet also helps connect astronauts to ground and space crews

• Touchscreen-sensitive gloves that allow astronauts to interact with the capsule’s tablets screens overhead

• Vents that allow astronauts to be cooler, but can still pressurize the suit immediately

• Breathable, slip resistant boots

• Zippers in the torso area will make it easier for astronauts to comfortably transition from sitting to standing

• Innovative layers will keep astronauts cooler

“The most important part is that the suit will keep you alive,” astronaut Eric Boe said, in a statement. “It is a lot lighter, more form-fitting and it’s simpler, which is always a good thing. Complicated systems have more ways they can break, so simple is better on something like this.”

The astronauts help the designers to perfect the suits very practically by wearing them inside Starliner mock-ups, moving around to accomplish tasks, reaching for the tablets screens, and climbing in and out of the capsule repeatedly, says Boe “so they can establish the best ways for astronauts to work inside the spacecraft’s confines.”

“The spacesuit acts as the emergency backup to the spacecraft’s redundant life support systems,” said Richard Watson, subsystem manager for spacesuits for NASA’s Commercial Crew Program.

“If everything goes perfectly on a mission, then you don’t need a spacesuit. It’s like having a fire extinguisher close by in the cockpit. You need it to be effective if it is needed.”

Boe is one of four NASA astronauts that form the core cadre of astronauts training for the initial flight tests aboard either the Boeing Starliner or SpaceX Crew Dragon now under development as part of NASA’s Commercial Crew program.

The inaugural flight tests are slated to begin in 2018 under contract to NASA.

The procedure on launch day will be similar to earlier manned launches. For Starliner, however, the capsule will launch atop a United Launch Alliance Atlas V rocket – currently being man-rated.

Astronauts will don the new ‘Boeing Blue’ suit in the historic Crew Quarters. The will ride out to the rocket inside an astrovan. After reaching Space Launch Complex 41, they will take the elevator up, stride across the recently installed Crew Access Arm and board Starliner as it stands atop a United Launch Alliance Atlas V rocket.

The first test flight will carry a crew of two. Soon thereafter the crew size will grow to four when regular crew rotation flights to the ISS starting as soon as 2019.

“To me, it’s a very tangible sign that we are really moving forward and we are a lot closer than we’ve been,” Ferguson said. “The next time we pull all this together, it might be when astronauts are climbing into the actual spacecraft.”

Boeing is currently manufacturing the Starliner spacecraft at the company’s Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.

1st Boeing Starliner Hull Assembled as 1st Crew Flight Delays to 2018

As completion nears for the prototype of Boeing’s first Starliner astronaut taxi, the aerospace firm announced a slip into 2018 for the blastoff date of the first crewed flight in order to deal with spacecraft mass, aerodynamic launch and flight software issues, a Boeing spokesperson told Universe Today.

Until this week, Boeing was aiming for a first crewed launch of the commercial Starliner capsule by late 2017, company officials had said.

The new target launch date for the first astronauts flying aboard a Boeing CST-100 Starliner “is February 2018,” Boeing spokeswoman Rebecca Regan told Universe Today.

“Until very recently we were marching toward the 2017 target date.”

Word of the launch postponement came on Wednesday via an announcement by Boeing executive vice president Leanne Caret at a company investor conference.

Boeing will conduct two critical unmanned test flights leading up to the manned test flight and has notified NASA of the revised flight schedule.

“The Pad Abort test is October 2017 in New Mexico. Boeing will fly an uncrewed orbital flight test in December 2017 and a crewed orbital flight test in February 2018,” Regan told me.

Previously, the uncrewed and crewed test flights were slated for June and October 2017.

The inaugural crew flight will carry two astronauts to the International Space Station including a Boeing test pilot and a NASA astronaut.

“Boeing just recently presented this new schedule to NASA that gives a realistic look at where we are in the development. These programs are challenging.”

“As we build and test we are learning things. We are doing everything we can to make sure the vehicle is ready and safe – because that’s what most important,” Regan emphasized.

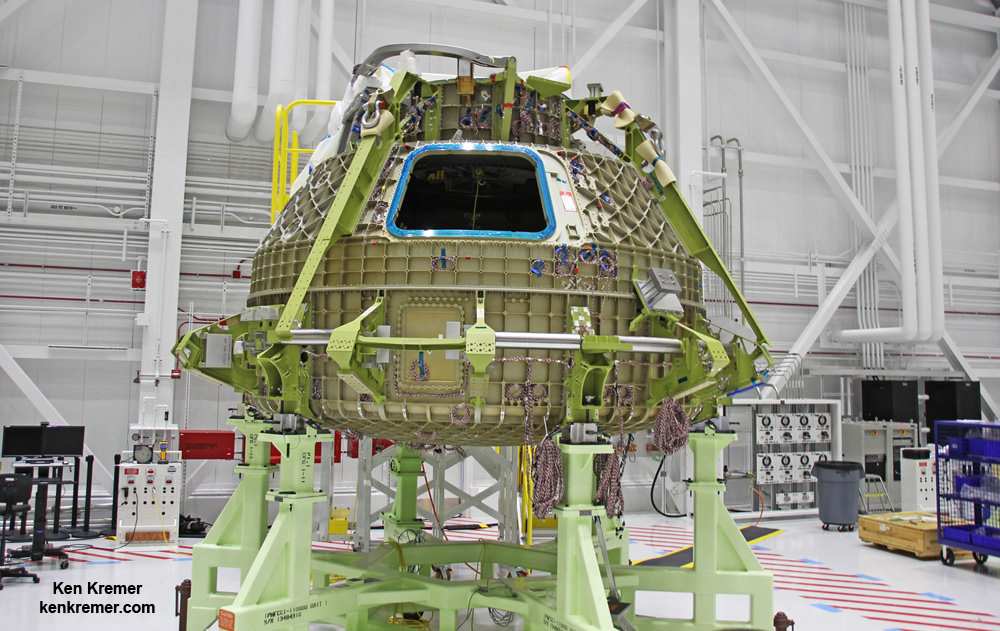

Indeed engineers just bolted together the upper and lower domes of Boeings maiden Starliner crew module last week, on May 2, forming the complete hull of the pressure vessel for the Structural Test Article (STA).

Altogether there are 216 holes for the bolts. They have to line up perfectly. The seals are checked to make sure there are no leaks, which could be deadly in space.

Starliner is being manufactured in Boeing’s Commercial Crew and Cargo Processing Facility (C3PF) at NASA’s Kennedy Space Center (KSC) in Florida.

The STA will be subjected to rigorous environmental and loads testing to prove its fitness to fly humans to space and survive the harsh extremes of the space environment.

Regan cited three technical factors accounting for the delayed launch schedule. The first relates to mass.

“There are a couple of things that impacted the schedule as discussed recently by John Elbon, Boeing vice president and general manager of Space Exploration.”

“First is mass of the spacecraft. Mass whether it’s from aircraft or spacecraft is obviously always something that’s inside the box. We are working that,” Regan stated.

The second relates to aerodynamic loads which Boeing engineers believe they may have solved.

“Another challenge is aero-acoustic issues related to the spacecraft atop the launch vehicle. Data showed us that the spacecraft was experiencing some pressures [during launch] that we needed to go work on more.”

Starliners will launch to space atop the United Launch Alliance (ULA) Atlas V rocket from pad 41 on Cape Canaveral Air Force Station in Florida.

“The aerodynamic acoustic loads data we were getting told us that we needed to go do some additional work. We actually now have a really viable option that we are testing right now in a wind tunnel this month.”

“So we think we are on the right path there. We have some design options we are looking at. We think we found a viable option that’s inside the scope of where we need to be on those aerodynamic acoustics in load.”

“So we will look at the data from the new wind tunnel tests.”

The third relates to new software requirements from NASA for docking at the ISS.

“NASA also levied some additional software requirements on us, in order to dock with the station. So those additional software requirements alone, in the contract, probably added about 3 months to our schedule, for our developers to work that.”

The Boeing CST 100 Starliner is one of two private astronaut capsules – along with the SpaceX Crew Dragon – being developed under a commercial partnership contract with NASA to end our sole reliance on Russia for crew launches back and forth to the International Space Station (ISS).

The goal of NASA’s Commercial Crew Program (CCP) is to restore America’s capability to launch American astronauts on American rockets from American soil to the ISS, as soon as possible.

Boeing was awarded a $4.2 Billion contract in September 2014 by NASA Administrator Charles Bolden to complete development and manufacture of the CST-100 Starliner space taxi under the agency’s Commercial Crew Transportation Capability (CCtCap) program and NASA’s Launch America initiative.

Since the retirement of NASA’s space shuttle program in 2011, the US was been 100% dependent on the Russian Soyuz capsule for astronauts rides to the ISS at a cost exceeding $70 million per seat.

Due to huge CCP funding cuts by Congress, the targeted launch dates for both Starliner and Crew Dragon have been delayed repeatedly from the initially planned 2015 timeframe to the latest goal of 2017.

The Structural Test Article plays a critical role serving as the pathfinder vehicle to validate the manufacturing and processing methods for the production of all the operational spacecraft that will follow in the future.

Although it will never fly in space, the STA is currently being built inside the renovated C3PF using the same techniques and processes planned for the operational spacecraft that will carry astronaut crews of four or more aloft to the ISS in 2018 and beyond.

“The Structural Test Article is not meant to ever fly in space but rather to prove the manufacturing methods and overall ability of the spacecraft to handle the demands of spaceflight carrying astronauts to the International Space Station,” says NASA.

The STA is also the first spacecraft to come together inside the former shuttle hangar known as an orbiter processing facility, since shuttle Discovery was moved out of the facility following its retirement and move to the Smithsonian’s Udvar-Hazy Center near Washington, D.C., in 2012.

“It’s actually bustling in there right now, which is awesome. Really exciting stuff,”Regan told me.

Regan also confirmed that the completed Starliner STA will soon be transported to Boeing’s facility in Huntington Beach, California for a period of critical stress testing that verifies the capabilities and worthiness of the spacecraft.

“Boeing’s testing facility in Huntington Beach, California has all the facilities to do the structural testing and apply loads. They are set up to test spacecraft,” said Danom Buck, manager of Boeing’s Manufacturing and Engineering team at KSC, during a prior interview in the C3PF.

“At Huntington Beach we will test for all of the load cases that the vehicle will fly in and land in – so all of the worst stressing cases.”

“So we have predicted loads and will compare that to what we actually see in testing and see whether that matches what we predicted.”

NASA notes that “the tests must bear out that the capsules can handle the conditions of space as well as engine firings and the pressure of launch, ascent and reentry. In simple terms, it will be shaked, baked and tested to the extreme.”

Lessons learned will be applied to the first flight test models of the Starliner. Some of those parts have already arrived at KSC and are “in the manufacturing flow in Florida.”

“Our team is initiating qualification testing on dozens of components and preparing to assemble flight hardware,” said John Mulholland, vice president and program manager of Boeing’s Commercial Programs, in a statement. “These are the first steps in an incredibly exciting, important and challenging year.”

SpaceX has announced plans to launch their first crew Dragon test flight before the end of 2017.

But the launch schedules for both Boeing and SpaceX are subject to review, dependent on satisfactorily achieving all agreed to milestones under the CCP contracts and approval by NASA, and can change at any time. So additional schedule alternations are not unexpected.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.

Buildup Of First Boeing Starliner Crew Vehicle Ramps Up at Kennedy Space Center

KENNEDY SPACE CENTER, FL – Buildup of the first of Boeing’s CST-100 Starliner crew spaceships is ramping up at the company’s Commercial Crew and Cargo Processing Facility (C3PF) – the new spacecraft manufacturing facility at NASA’s Kennedy Space Center.

In less than two years time Boeing Starliners will start launching NASA astronauts to low Earth orbit and the International Space Station (ISS) atop Atlas V rockets from Florida. Continue reading “Buildup Of First Boeing Starliner Crew Vehicle Ramps Up at Kennedy Space Center”

Construction of Crew Access Tower Starts at Atlas V Pad for Boeing ‘Starliner’ Taxi to ISS

The first tier of seven tiers for Crew Access Tower is moved from its construction yard to Space Launch Complex-41 at Cape Canaveral Air Force Station in Florida on Sept 9, 2015. The tower will provide access at the pad for astronauts and ground support teams to the Boeing CST-100 Starliner launching atop a United Launch Alliance Atlas V rocket. Photo credit: NASA/Dmitrios Gerondidakis

Story/photos updated[/caption]

KENNEDY SPACE CENTER, FL – Restoring America’s human path back to space from US soil kicks into high gear at last as construction starts on erecting the new crew access tower on the Atlas V launch pad that will soon propel Americans astronauts riding aboard the commercially developed Boeing CST-100 ‘Starliner’ taxi to the Earth-orbiting International Space Station (ISS).

The last hurdle to begin stacking the crew access tower at the United Launch Alliance Atlas V complex-41 launch pad on Cape Canaveral Air Force Station, Florida was cleared with the magnificent predawn blastoff of the U.S. Navy’s MUOS-4 communications satellite on Sept. 2 – following a two day weather delay due to Tropical Storm Erika.

“Everything is on schedule,” Howard Biegler, ULA’s Human Launch Services Lead, told Universe Today during an exclusive interview. “The new 200-foot-tall tower structure goes up rather quickly at launch pad 41.”

The access tower essentially functions as the astronauts walkway to the stars.

“We start stacking the crew access tower [CAT] after the MUOS-4 launch and prior to the next launch after that of Morelos-3,” Beigler said in a wide ranging interview describing the intricately planned pad modifications and tower construction at the Atlas V Space Launch Complex 41 facility at Cape Canaveral.

Depending on the always tricky weather at the Cape, more than half the tower should be “installed prior to MORELOS-3’s launch on Oct. 2. The balance of the CAT will take form after the launch.”

The crew access tower is a critical space infrastructure element and absolutely essential for getting Americans back to space on American rockets for the first time since NASA’s shuttles were retired in 2011. That action forced our total dependence on the Russian Soyuz capsule for astronaut rides to the space station.

Boeing was awarded a $4.2 Billion contract in September 2014 by NASA Administrator Charles Bolden to complete development and manufacture of the CST-100 space taxi under the agency’s Commercial Crew Transportation Capability (CCtCap) program and NASA’s Launch America initiative. SpaceX also received a NASA award worth $2.6 Billion to build the Crew Dragon spacecraft for launch atop the firms man-rated Falcon 9 rocket.

Starliner is a key part of NASA’s overarching strategy to send Humans on a “Journey to Mars” in the 2030s.

The tower is of modular design for ease of assembly at the always busy Atlas launch pad.

“The crew tower is comprised of seven major tiers, or segments,” Beigler explained. “The building of the tiers went right on schedule. Each tier is about 20 feet square and 28 feet tall.”

Five of the seven tiers will be installed ahead of the next Atlas launch in early October, depending on the weather which has been difficult at the Cape.

“Our plan is to get 5 tiers and a temporary roof installed prior to MORELOS-3’s launch on October 2.”

“We have been hit hard with weather and are hopeful we can gain some schedule through the weekend. The balance of the CAT will take form after the 10/2 launch with the 7th tier planned to go up on 10/13 and roof on 10/15,” Biegler explained.

The newly named ‘Starliner’ space taxi will launch atop a newly human-rated Atlas V booster as soon as mid-2017, say NASA, ULA and Boeing officials.

But before astronauts can even climb aboard Starliner atop the Atlas rocket, ULA and Boeing first had to design, build and install a brand new tower providing access to the capsule for the crews and technicians.

Pad 41 is currently a “clean pad” with no gantry and no walkway to ‘Starliner’ because the Atlas V has only been used for unmanned missions to date.

The CST-100 ‘Starliner’ is at the forefront of ushering in the new commercial era of space flight and will completely revolutionize how we access, explore and exploit space for the benefit of all mankind.

This is the first new Crew Access Tower to be built at the Cape in decades, going back to NASA’s heyday and the Apollo moon landing era.

The tier segments were assembled about four miles down the road at the Atlas Space Operations Center on Cape Canaveral – so as not to disrupt the chock full manifest of Atlas rockets launching on a breakneck schedule for the NASA, military and commercial customers who ultimately pay the bills to keep ULA afloat and launch groundbreaking science probes and the most critical national security payloads vital to national defense.

“Each segment was outfitted with additional steel work, as well as electrical, plumbing and the staircase. Then they will be transported 3.9 miles out to the pad, one at a time on a gold hoffer and then we start erecting.”

The first two tiers were just transported out to pad 41. Installation and stacking of one tier on top of another starts in a few days.

“We are very pleased with the progress so far,” Biegler told me. “Everything is on schedule and has gone remarkably well so far. No safety or workmanship issues. It’s all gone very well.”

“The first tier is obviously the most critical [and will take a bit longer than the others to insure that everything is being done correctly]. It has to be aligned precisely over the anchor bolts on the foundation at the pad. Then it gets bolted in place.”

“After that they can be installed every couple of days, maybe every three days or so. The pieces of the tower will go up quickly.”

“Construction by the Hensel Phelps team started in January 2015,” Biegler said.

Erecting the entire tower is the next step. After stacking the tiers is fully completed later this year then comes structure, testing and calibration work over the next year.

“After tower buildup comes extensive work to outfit the tower with over 400 pieces of outboard steel that have to be installed. That takes much longer,” Biegler said.

“Designed with modern data systems, communications and power networks integrated and protected from blast and vibration, plus an elevator, the Crew Access Tower has been built with several features only a fully suited astronaut could appreciate, such as wider walkways, snag-free railings and corners that are easy to navigate without running into someone,” according to NASA officials.

Just like the shuttle, “the tower will also be equipped with slide wire baskets for emergency evacuation to a staged blast-resistant vehicle.”

“At the very top is the area that protects the access arm and provides the exit location for the emergency egress system. It will all be stick built from steel out at the pad,” Biegler elaborated.

The access arm with the walkway that astronauts will traverse to the Starliner capsule is also under construction. It is about 180 feet above ground.

Astronauts will ride an elevator up the tower to the access arm, and walk through it to the white room at the end to board the Starliner capsule.

“The arm along with the white room and torque tube are being fabricated in Florida. It will all be delivered to the pad sometime around next June [2016],” Biegler stated.

“We built a test stand tower for the access arm at our Oak Hill facility to facilitate the installation process. We mount the arm and the hydraulic drive system and then run it through its paces prior to its delivery to the pad.”

“The access arm – including the torque tube out to the end – is just over 40 feet in length.”

“We will integrate it off line because we don’t have a lot of time to troubleshoot out at the pad. So we will hook up all its drive systems and electronics on the test structure stand.”

“Then we will spend about 3 months testing it and verifying that everything is right. We’ll use laser lining to know it all precisely where the arm is. So that when we bring it out to the pad we will know where it is to within fractions of an inch. Obviously there will be some minor adjustments up and down.”

“That way in the end we will know that everything in the arm and the hydraulic drive system are working within our design specs.”

When the arm is finally installed on the crew access tower it will be complete, with the white room and environmental seal already attached.

“It will stow under the crew access tower, which is located west and north of the launch vehicle. The arm will swing out about 120 degrees to the crew module to gain access and was strategically picked to best fit the features and foundation at the existing pad structure.”

Tower construction takes place in between Atlas launches and pauses in the days prior to launches. For example the construction team will stand down briefly just ahead of the next Atlas V launch currently slated for Oct. 2 with the Mexican governments Morelos-3 communications satellite.

Starliners’ actual launch date totally depends on whether the US Congress provides full funding for NASA’s commercial crew program (CCP).

Thus far the Congress has totally failed at providing the requested CCP budget to adequately fund the program – already causing a 2 year delay of the first flight from 2015 to 2017.

Boeing is making great progress on manufacturing the first CST-100 Starliner.

Barely a week ago, Boeing staged the official ‘Grand Opening’ ceremony for the craft’s manufacturing facility held at the Kennedy Space Center on Friday, Sept 4. 2015 – attended by Universe Today as I reported here.

ULA has also already started assembly of the first two Atlas V rockets designated for Starliner at their rocket factory in Decatur, Alabama.

Read my earlier exclusive, in depth one-on-one interviews with Chris Ferguson – America’s last shuttle commander, who now leads Boeings’ CST-100 program; here and here.

Stay tuned here for Ken’s continuing Earth and planetary science and human spaceflight news.