Material science plays an absolutely critical role in space exploration. So when a new type of self-healing composite is announced, it’s worth a look–especially when the press release specifically calls out its ability to repair microtears associated with micrometeoroid impacts on satellites. It sounds like just such a composite material was recently invented at North Carolina State University - and it’s even already been spun out into a start-up company.

At the technology’s core is a well-known material - fiber-reinforced polymer (FRP). FRP is commonly used in everything from wind turbines to spacecraft, and has plenty of strengths, such as extremely good physical properties with lower weight. But it also has one big weakness. Delamination, or when the layers of polymer begin to unstick from each other, is one of FRP’s most common failure modes.

Typically, a sheet of FRP can last anywhere between 15-40 years, which might seem like a long time. But, in the context of huge infrastructure projects or airplanes that might operate for more than twice that time, it either requires replacement or expensive manual repair to fix all the delamination that happened over that time.

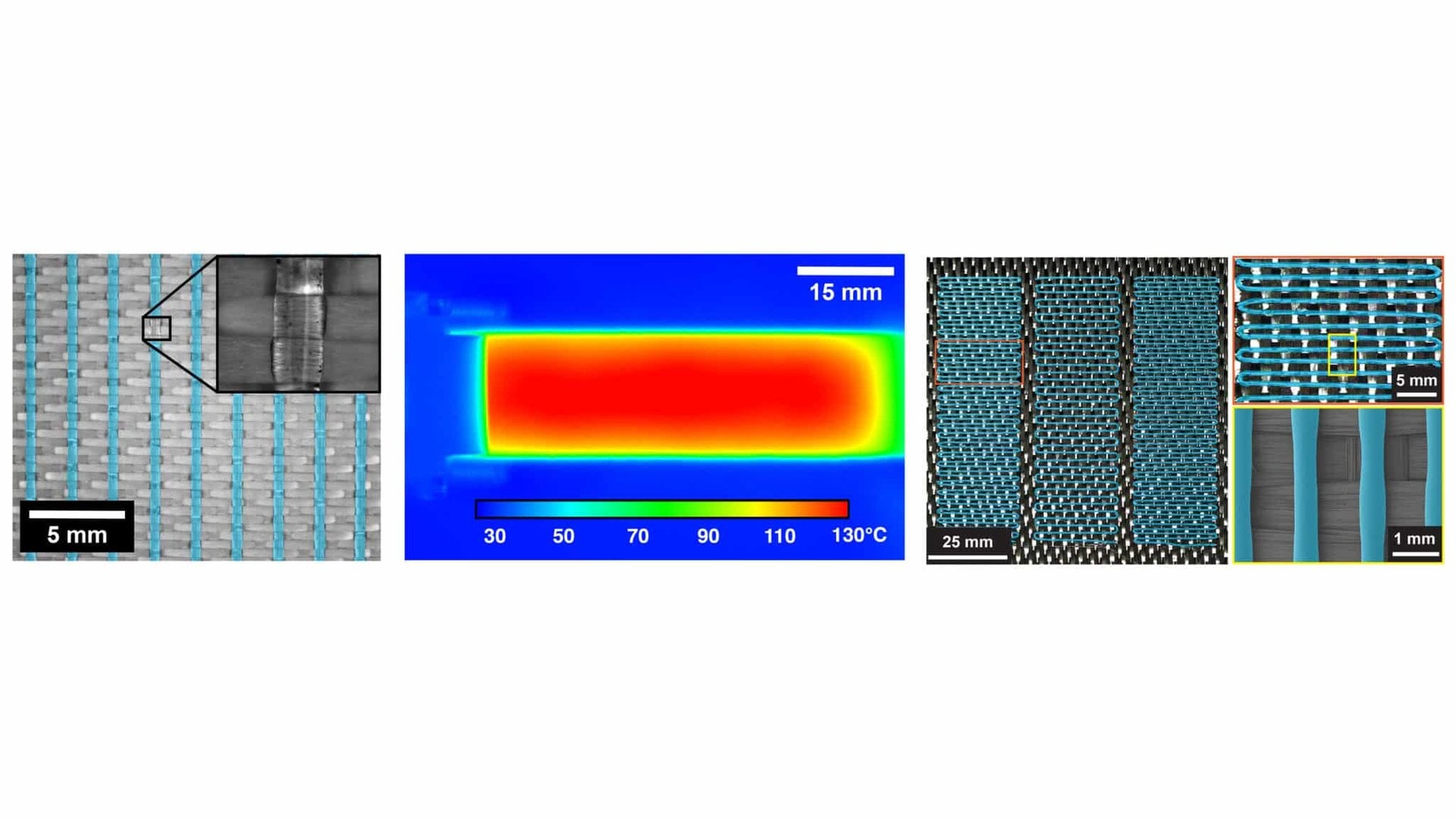

Video from NC State describing the technology. Credit - Civil, Construction, & Environmental Engineering YouTube ChannelTackling this problem required a two-pronged approach from the team at NCSU led by Jason Patrick, an associate professor in the Civil, Construction, and Environmental Engineering Department at NC State. First, they 3D-print a type of thermoplastic called EMAA directly onto the layers of FRP fiber. Even this change made the original material about 2-4 times more resistant to delamination than traditional composites.

But the real magic was also embedding carbon-based heaters in other layers as well. When a current is applied to them, they warm the EMAA so it flows into the cracks caused by the delamination and “welds” the layers back together. Seems like a simple idea - but implementing it was probably harder than it sounds.

They did manage to, though, and spent 40 days intentionally breaking and reassembling samples of their modified composite. Over that time they “broke” and repaired it over 1000 times. For the first 500 times, the composite remained stronger than typical composite. However, after a while, fiber debris accumulated in the system, causing the strength to decrease slightly.

Video describing a similar technology that self-heals with heat. Credit - EPFL YouTube ChannelDespite the decline in performance, it still worked much better than a composite that had delaminated. It also has major advantages over other previously “self-healing” technologies. Most of them used a single “microcapsule” in a given area filled with liquid glue. When a crack formed, the capsule broke and the glue leaked out, but it was a one-time repair. NC State’s invention, on the other hand, is able to perform a repair on the same place more than 1,000 times.

Such a technology would be useful in plenty of places, but perhaps the most notable is wind turbines. They are notoriously difficult to recycle and have a life span of only around 20 years, despite being made largely of FRP. Increasing that life to the estimated 100+ years of the new composite would be a game changer for the economics of that particular green energy source, and also solve a major waste issue when disposing of them.

But this is a space and astronomy blog, so obviously we have to talk about how it could be used in outer space. Spacecraft, and potentially even bases on worlds with negligible atmospheres, like the Moon and Mars, are constantly being pelted by micrometeoroids. These cause micro-sized cracks in equipment, the exact kind of problem this technology is designed to solve. Since the only resource needed is electrical power, and the craft is already gathering that to run the rest of its systems, it seems a shoe-in to implement these self-healing materials into future deep-space missions.

Video describing some of the misconceptions of carbon fiber, a type of composite the new technology is supposed to help. Credit - DarkAero, Inc. YouTube ChannelTo support that effort, Dr. Patrick has spun out a company called Structeryx Inc. that has licensed the technology from the University. It plans to work with partners to find potential use cases for the technology. To be clear, it is certainly not a “cure-all” for FRP-related woes. The press release is from the university itself, so it only highlights the good side, not the potential downsides. Increasing the weight might make it a non-starter for spacecraft missions, but also for general aerospace applications. And increasing the price could undercut some of the economic advantages it would give wind turbine manufacturers.

As with all new technologies, it still has a long way to go for widespread adoption. But in this case, if the technology does work as planned, it seems like it has a ready-made use case as the go-to structural material for future deep-space missions.

Learn More:

NC State - Self-Healing Composite Can Make Airplane, Automobile and Spacecraft Components Last for Centuries

J. Turiecek et al - Self-healing for the long haul: In situ automation delivers century-scale fracture recovery in structural composites

UT - Self-Repairing Spacecraft

UT - A Self-Healing Satellite? Students Seek Your Funds To Launch Prototype

Universe Today

Universe Today