CAPE CANAVERAL AIR FORCE STATION, FL – Assembly of the powerful Delta IV rocket boosting the pathfinder version of NASA’s Orion crew capsule on its maiden test flight in December has been completed.

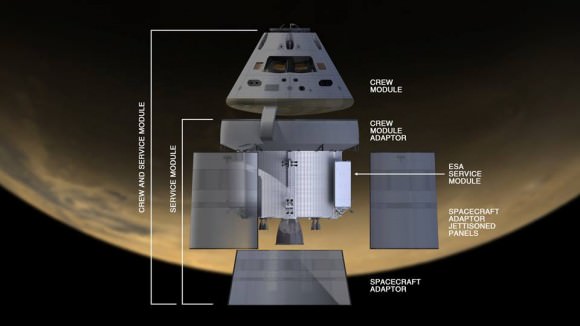

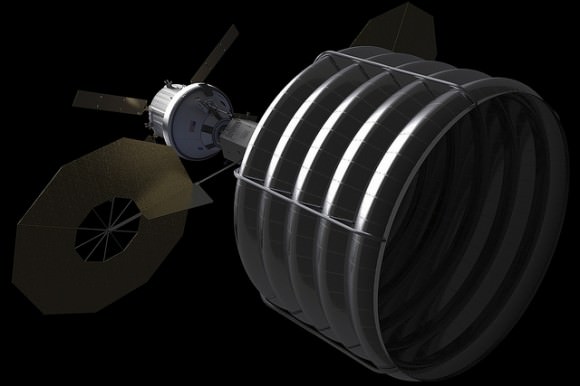

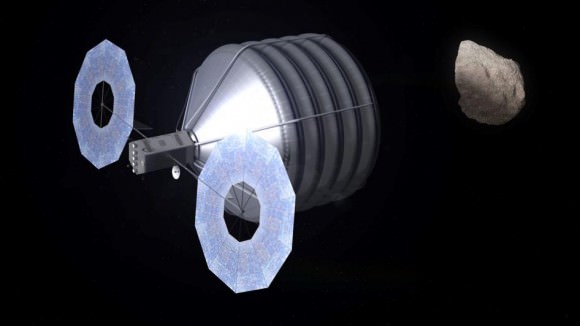

Orion is NASA’s next generation human rated vehicle that will eventually carry America’s astronauts beyond Earth on voyages venturing farther into deep space than ever before – beyond the Moon to Asteroids, Mars and other destinations in our Solar System.

The state-of-the-art Orion spacecraft is scheduled to launch on its inaugural uncrewed mission, dubbed Exploration Flight Test-1 (EFT-1), in December 2014 atop the Delta IV Heavy rocket. It replaces NASA’s now retired space shuttle orbiters.

The triple barreled Delta IV Heavy is currently the most powerful rocket in America’s fleet following the retirement of the NASA’s Space Shuttle program.

Engineers from the rocket’s manufacturer – United Launch Alliance (ULA) – took a major step forward towards Orion’s first flight when they completed the integration of the three primary core elements of the rockets first stage with the single engine upper stage.

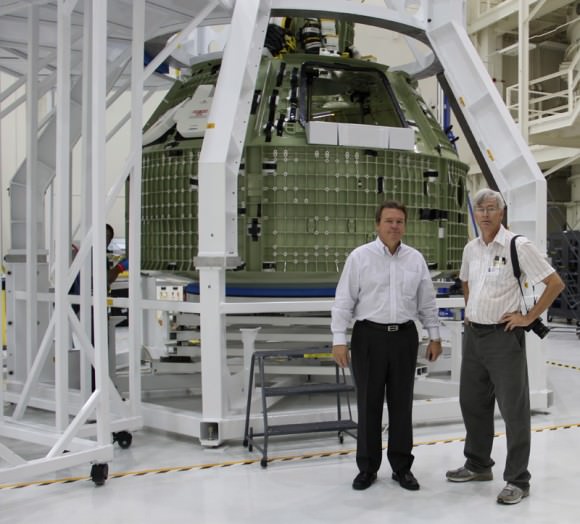

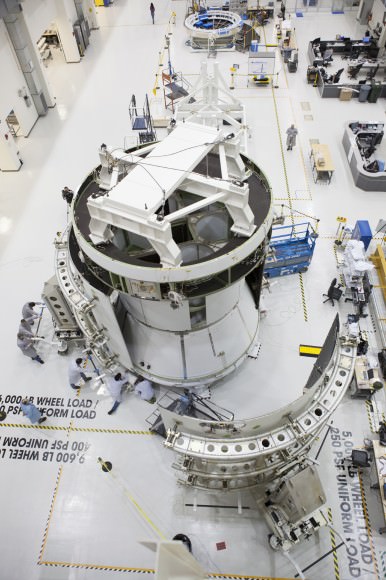

All of the rocket integration work and preflight processing took place inside ULA’s Horizontal Integration Facility (HIF), at Cape Canaveral Air Force Station in Florida.

Universe Today recently visited the Delta IV booster during an up close tour inside the HIF facility last week where the rocket was unveiled to the media in a horizontally stacked configuration. See my Delta IV photos herein.

The HIF building is located at Space Launch Complex 37 (SLC-37), on Cape Canaveral, a short distance away from the launch pad where the Orion EFT-1 mission will lift off on Dec. 4.

“The day-to-day processing is performed by ULA,” said Merri Anne Stowe of NASA’s Fleet Systems Integration Branch of the Launch Services Program (LSP), in a NASA statement.

“NASA’s role is to keep a watchful eye on everything and be there to help if any issues come up.”

The first stage is comprised of a trio of three Delta IV Common Booster Cores (CBCs).

Each CBC measures 134 feet in length and 17 feet in diameter. They are equipped with an RS-68 engine powered by liquid hydrogen and liquid oxygen propellants producing 656,000 pounds of thrust. Together they generate 1.96 million pounds of thrust.

This past spring I visited the HIF after the first two CBCs arrived by barge from their ULA assembly plant in Decatur, Alabama, located about 20 miles west of Huntsville.

The first CBC booster was attached to the center booster in June. The second one was attached in early August, according to ULA.

“After the three core stages went through their initial inspections and processing, the struts were attached, connecting the booster stages with the center core,” Stowe said. “All of this takes place horizontally.”

The Delta IV cryogenic second stage testing and attachment was completed in August and September. It measures 45 feet in length and 17 feet in diameter. It is equipped with a single RL10-B-2 engine, that also burns liquid hydrogen and liquid oxygen propellant and generates 25,000 pounds of thrust.

“The hardware for Exploration Flight Test-1 is coming together well,” Stowe noted in a NASA statement.

“We haven’t had to deal with any serious problems. All of the advance planning appears to be paying off.”

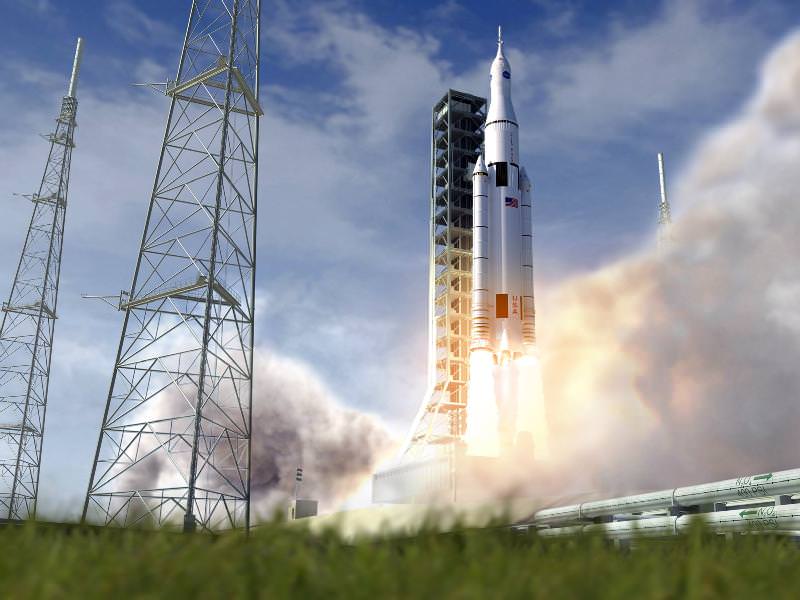

This same Delta IV upper stage will be used in the Block 1 version of NASA’s new heavy lift rocket, the Space Launch System (SLS).

Be sure to read my recent article detailing the ribbon cutting ceremony opening the manufacture of the SLS core stage at NASA’s Michoud Assembly Facility in New Orleans, LA. The SLS will be the most powerful rocket ever built by humans, exceeding that of the iconic Saturn V rocket that sent humans to walk on the surface of the Moon.

The Delta IV rocket will be rolled out to the SLC-37 Cape Canaveral launch pad this week.

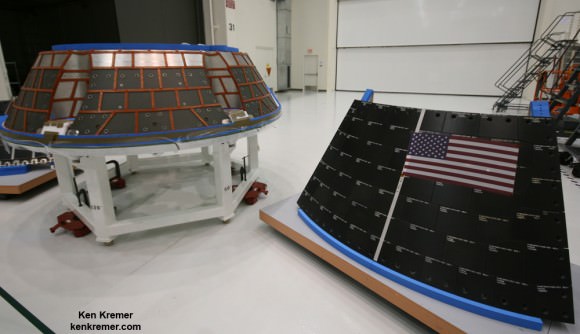

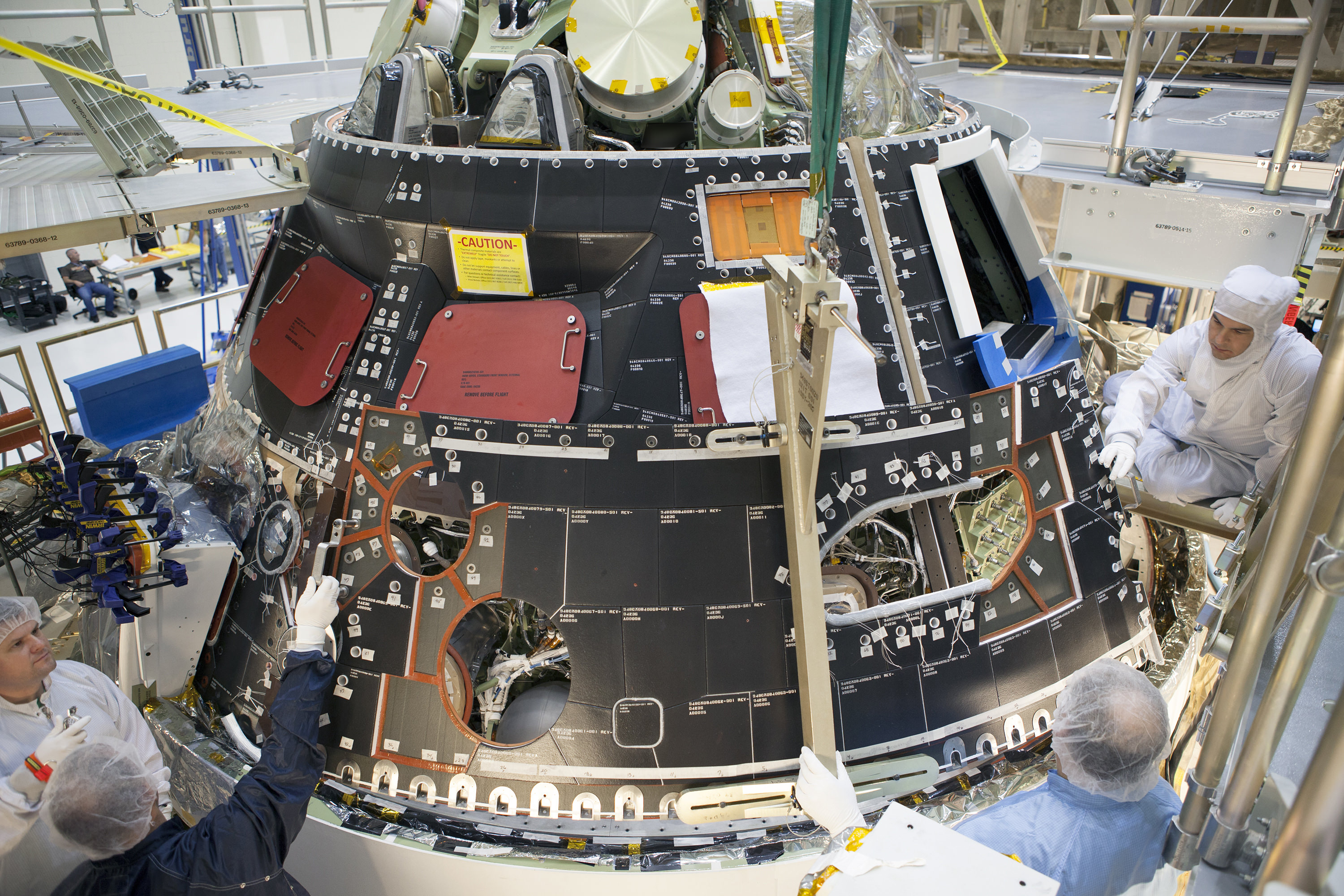

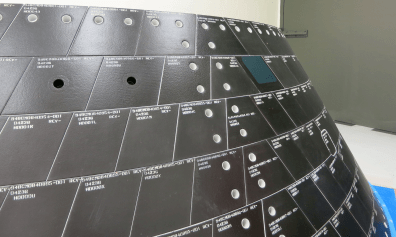

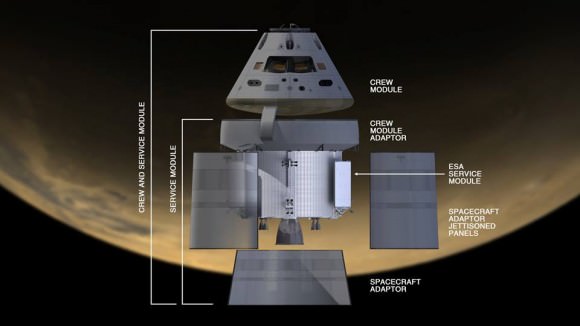

Assembly of the Orion EFT-1 capsule and stacking atop the service module was also completed in September at the Kennedy Space Center (KSC).

I was also on hand at KSC when the Orion crew module/service module (CM/SM) stack was rolled out on Sept. 11, 2014, on a 36-wheel transporter from its high bay assembly facility in the Neil Armstrong Operations and Checkout Building.

It was moved about 1 mile to its next stop on the way to SLC-37 – the KSC fueling facility named the Payload Hazardous Servicing Facility (PHFS). Read my Orion move story here.

The two-orbit, four and a half hour EFT-1 flight will lift the Orion spacecraft and its attached second stage to an orbital altitude of 3,600 miles, about 15 times higher than the International Space Station (ISS) – and farther than any human spacecraft has journeyed in 40 years.

Stay tuned here for Ken’s continuing Orion, SLS, Boeing, Sierra Nevada, Orbital Sciences, SpaceX, commercial space, Curiosity, Mars rover, MAVEN, MOM and more Earth and planetary science and human spaceflight news.