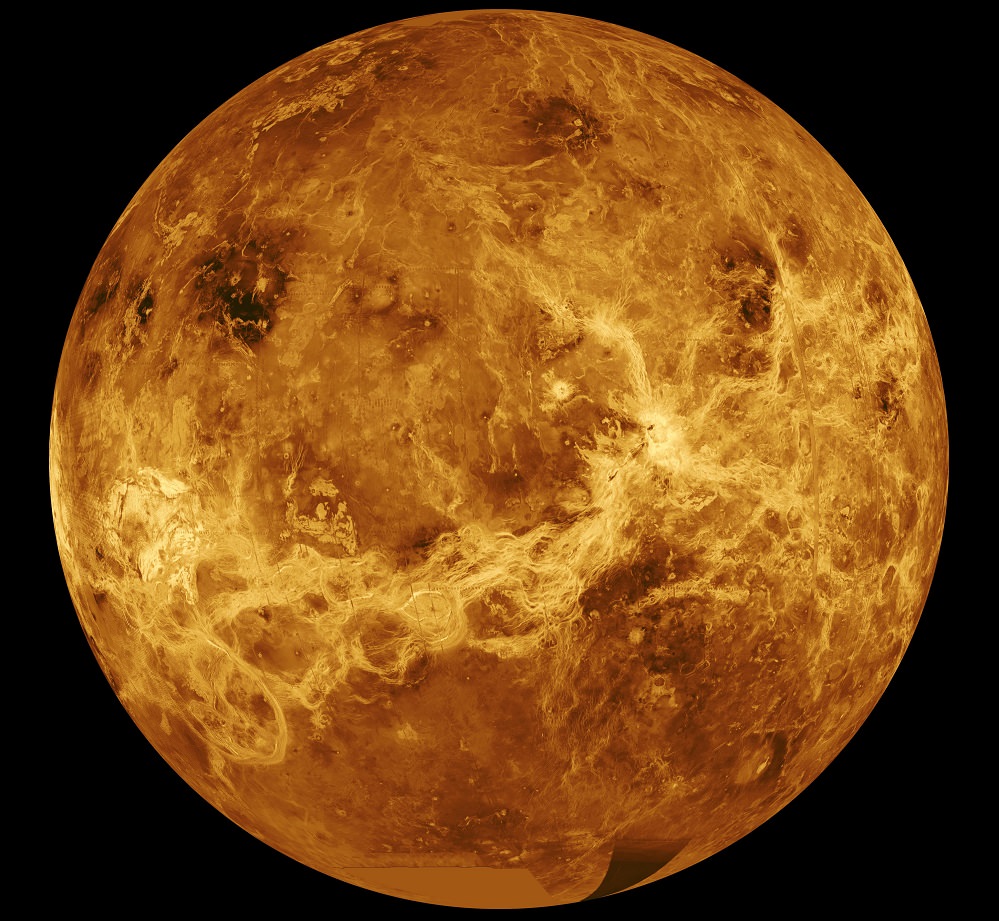

The weather on Venus is like something out of Dante’s Inferno. The average surface temperature – 737 K (462 °C; 864 °F) – is hot enough to melt lead and the atmospheric pressure is 92 times that of Earth’s at sea level (9.2 MPa). For this reason, very few robotic missions have ever made it to the surface of Venus, and those that have did not last long – ranging from about 20 minutes to just over two hours.

Hence why NASA, with an eye to future missions, is looking to create robotic missions and components that can survive inside Venus’ atmosphere for prolonged periods of time. These include the next-generation electronics that researchers from NASA Glenn Research Center (GRC) recently unveiled. These electronics would allow a lander to explore Venus surface for weeks, months, or even years.

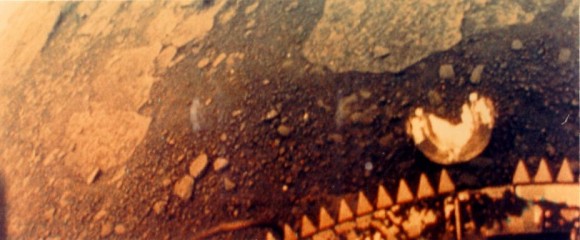

In the past, landers developed by the Soviets and NASA to explore Venus – as part of the Venera and Mariner programs, respectively – relied on standard electronics, which were based on silicon semiconductors. These are simply not capable of operating in the temperature and pressure conditions that exist on the surface of Venus, and therefore required that they have protective casings and cooling systems.

Naturally, it was only a matter of time before these protections failed and the probes stopped transmitting. The record was achieved by the Soviets with their Venera 13 probe, which transmitted for 127 minutes between its descent and landing. Looking ahead, NASA and other space agencies want to develop probes that can gather as much information as they can on Venus’s atmosphere, surface, and geological history before they time out.

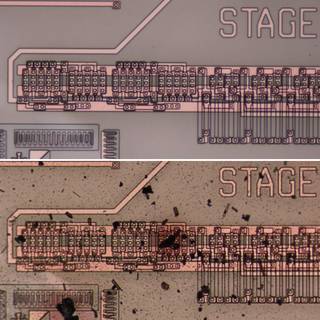

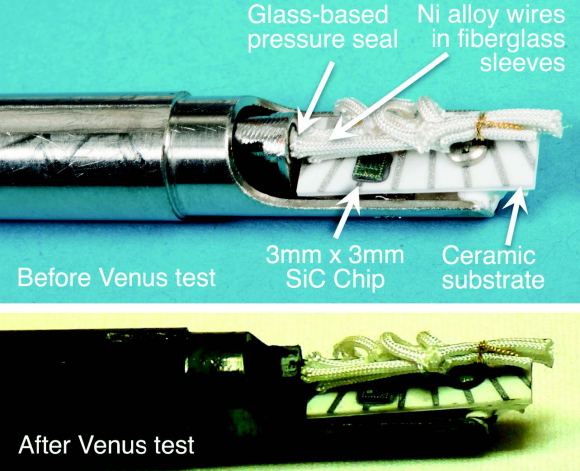

To do this, a team from NASA’s GRC has been working to develop electronics that rely on silcon carbide (SiC) semiconductors, which would be capable of operating at or above Venus’ temperatures. Recently, the team conducted a demonstration using the world’s first moderately-complex SiC-based microcircuits, which consisted of tens or more transistors in the form of core digital logic circuits and analog operation amplifiers.

These circuits, which would be used throughout the electronic systems of a future mission, were able to operate for up to 4000 hours at temperatures of 500 °C (932 °F) – effectively demonstrated that they could survive in Venus-like conditions for prolonged periods. These tests took place in the Glenn Extreme Environments Rig (GEER), which simulated Venus’ surface conditions, including both the extreme temperature and high pressure.

Back in April of 2016, the GRC team tested a SiC 12-transistor ring oscillator using the GEER for a period of 521 hours (21.7 days). During the test, they raised they subjected the circuits to temperatures of up to 460 °C (860 °F), atmospheric pressures of 9.3 MPa and supercritical levels of CO² (and other trace gases). Throughout the entire process, the SiC oscillator showed good stability and kept functioning.

This test was ended after 21 days due to scheduling reasons, and could have gone on much longer. Nevertheless, the duration constituted a significant world record, being orders of magnitude longer than any other demonstration or mission that has been conducted. Similar tests have shown that ring oscillator circuits can survive for thousands of hours at temperatures of 500 °C (932 °F) in Earth-air ambient conditions.

Such electronics constitute a major shift for NASA and space exploration, and would enable missions that were previously impossible. NASA’s Science Mission Direction (SMD) plans to incorporate SiC electronics on their Long-Life In-situ Solar System Explorer (LLISSE). A prototype is currently being developed for this low-cost concept, which would provide basic, but highly valuable scientific measures from the surface of Venus for months or longer.

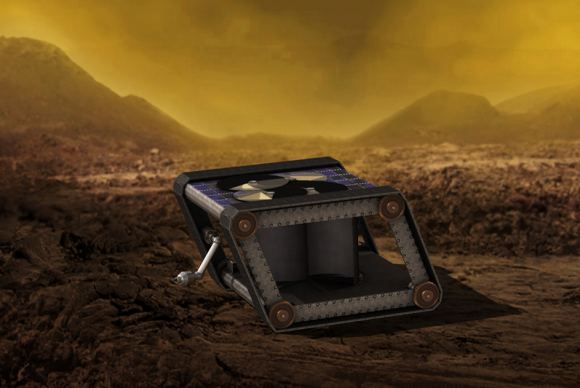

Other plans to build a survivable Venus explorer include the Automaton Rover for Extreme Environments (AREE), a “steampunk rover” concept that relies on analog components rather than complex electronic systems. Whereas this concepts seeks to do away with electronics entirely to ensure a Venus mission could operate indefinitely, the new SiC electronics would allow more complex rovers to continue operating in extreme conditions.

Beyond Venus, this new technology could also lead to new classes of probes capable of exploring within gas giants – i.e. Jupiter, Saturn, Uranus and Neptune – where temperature and pressure conditions have been prohibitive in the past. But a probe that relies on a hardened shell and SiC electronic circuits could very well penetrate deep into the interior of these planets and reveal startling new things about their atmospheres and magnetic fields.

The surface of Mercury could also be accessible to rovers and landers using this new technology – even the day-side, where temperatures reach a high of 700 K (427 °C; 800 °F). Here on Earth, there are plenty of extreme environments that could now be explored with the help of SiC circuits. For example, drones equipped with SiC electronics could monitor deep-sea oil drilling or explore deep into the Earth’s interior.

There are also commercial applications involving aeronautical engines and industrial processors, where extreme heat or pressure traditionally made electronic monitoring impossible. Now such systems could be made “smart”, where they are capable of monitoring themselves instead of relying on operators or human oversight.

With extreme circuits and (someday) extreme materials, just about any environment could be explored. Maybe even the interior of a star!

Further Reading: NASA