The European Space Agency (ESA) has made incredible contributions to space exploration and space-based science. Last year, the agency launched the Euclid space telescope, which will survey the Universe back to 3 billion years after the Big Bang to measure cosmic expansion and the influence of Dark Energy. After more than a decade of development, the Ariane 6 launch vehicle conducted its first full-scale dress rehearsal, which included an engine fire test. In a recent video, the ESA showcased its plans for the future, which include some new launch vehicles and engine technology.

Continue reading “ESA Gives Us a Glimpse of its Future Space Exploration Plans with a Cool New Video”NASA Tests a 3D Printed Aluminum Rocket Nozzle

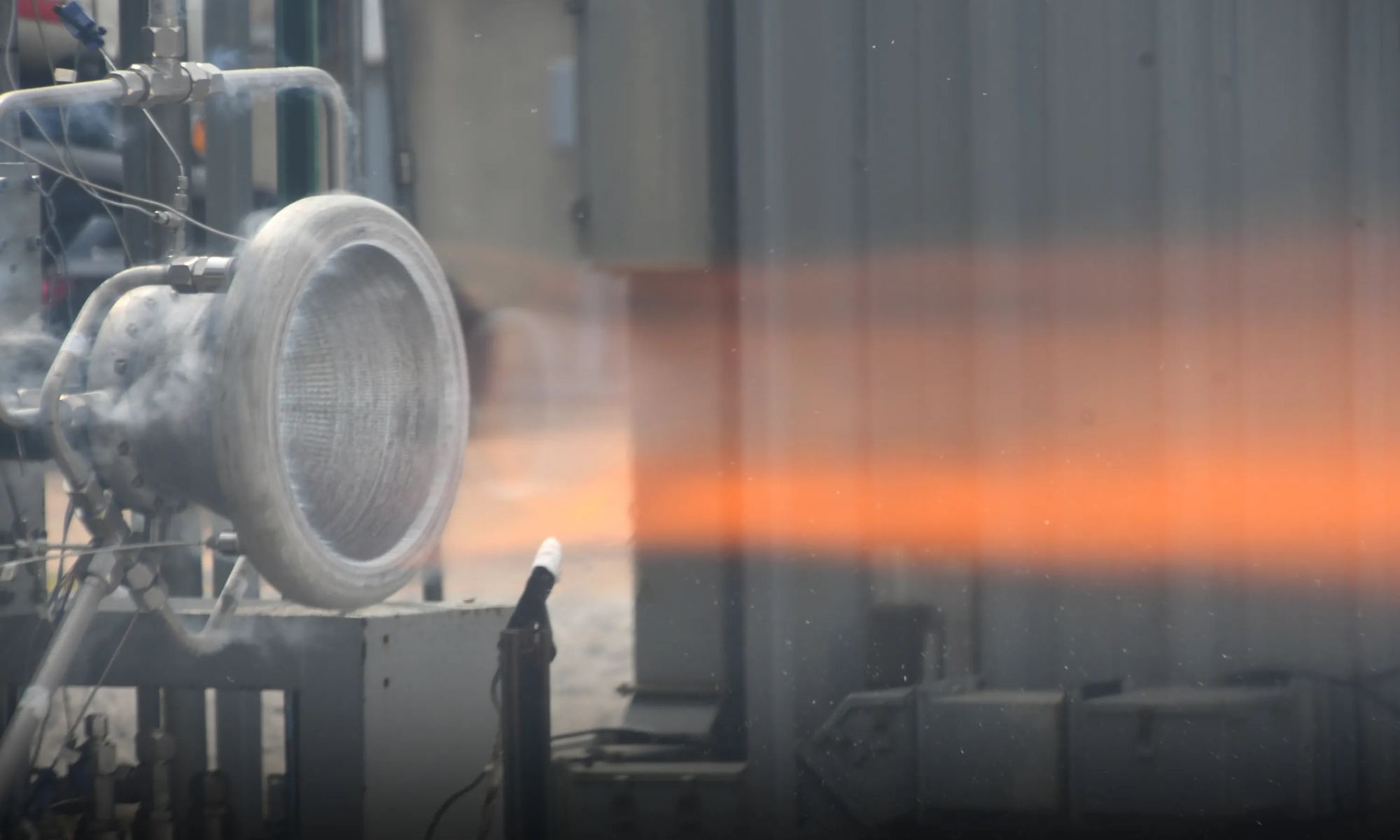

When it comes to the current era of space exploration, one of the most important trends is the way new technologies and processes are lowering the cost of sending crews and payloads to space. Beyond the commercial space sector and the development of retrievable and reusable rockets, space agencies are also finding new ways to make space more accessible and affordable. This includes NASA, which recently built and tested an aluminum rocket engine nozzle manufactured using their new Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) process.

Continue reading “NASA Tests a 3D Printed Aluminum Rocket Nozzle”Using Bacteria to Build a Base on Mars

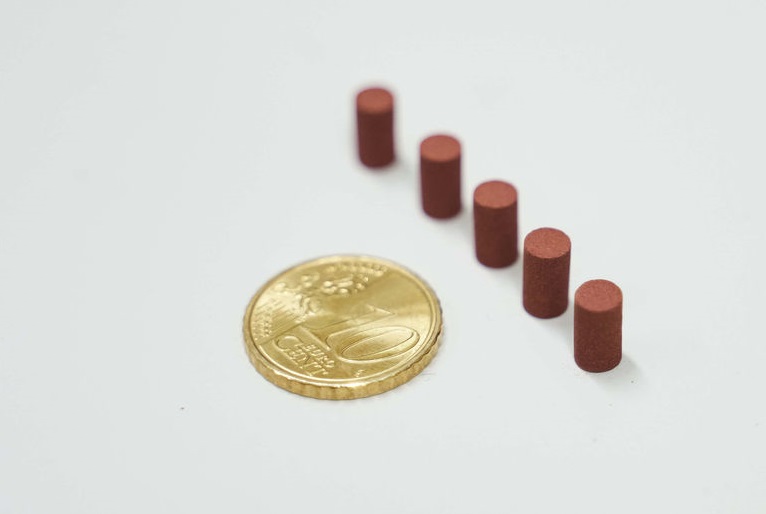

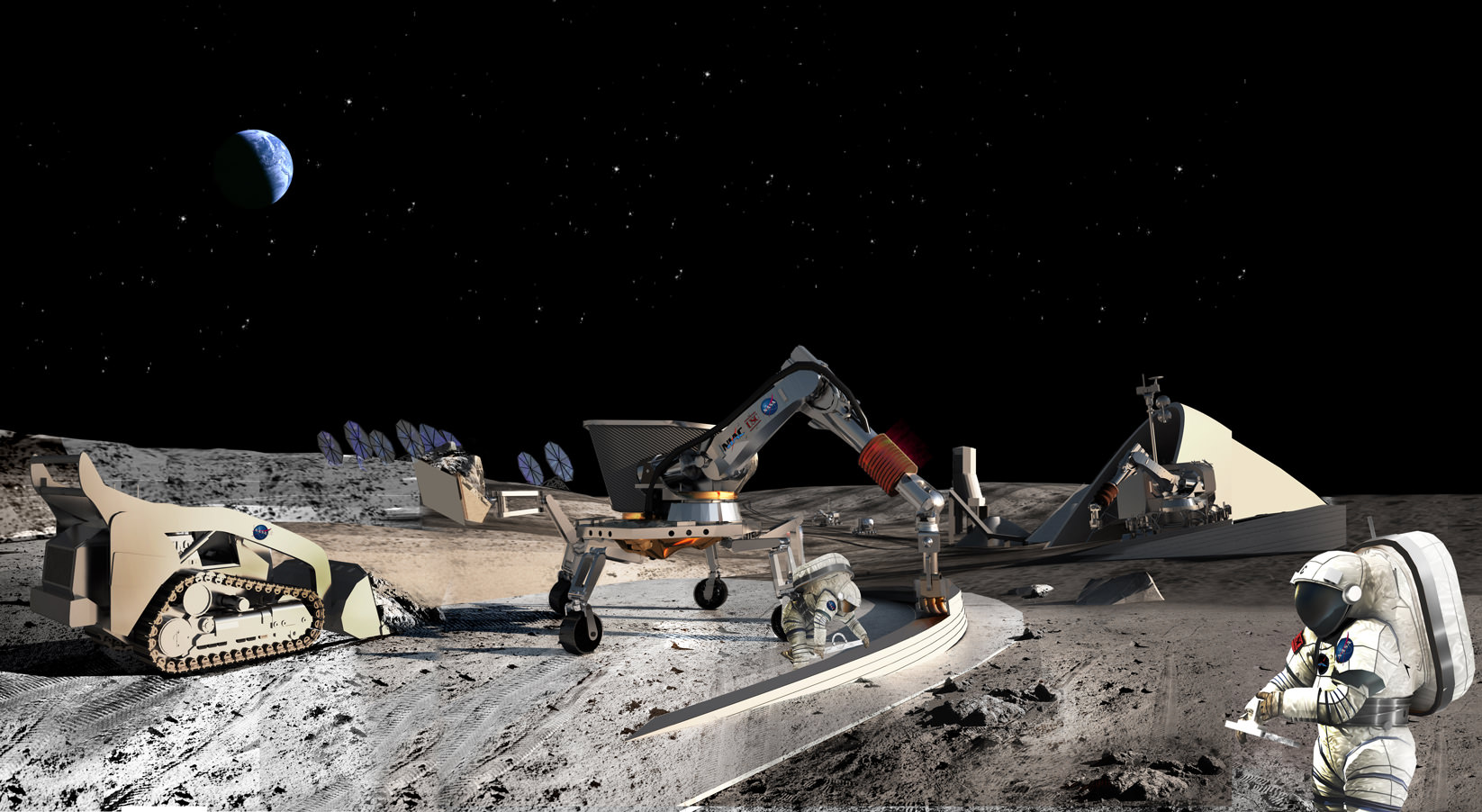

When it comes to plans for future missions to space, one of the most important aspects will be the use of local resources and autonomous robots. This process is known as In-Situ Resource Utilization (ISRU), which reduces the amount of equipment and resources that need to be sent ahead or brought along by a mission crew. Meanwhile, autonomous robots can be sent ahead of a crew and have everything prepared for them in advance.

But what about bacteria that can draw iron from extraterrestrial soil, which would then be used to 3D print metal components for a base? That is the idea that is being proposed by PhD candidate Benjamin Lehner of the Delft University of Technology. On Friday (Nov. 22nd), he defended his thesis, which calls for the deployment of an uncrewed mission to Mars that will convert regolith into useable metal using a bacteria-filled bioreactor.

Continue reading “Using Bacteria to Build a Base on Mars”Astronomy Cast Ep. 509: Fiction to Fact: 3D Printers

The technology of 3D printing is taking off. From tiny home-based 3D printers to larger manufacturing. And of course, 3D printing is going to space with the International Space Station and beyond.

We usually record Astronomy Cast every Friday at 3:00 pm EST / 12:00 pm PST / 20:00 PM UTC. You can watch us live on AstronomyCast.com, or the AstronomyCast YouTube page.

Visit the Astronomy Cast Page to subscribe to the audio podcast!

If you would like to support Astronomy Cast, please visit our page at Patreon here – https://www.patreon.com/astronomycast. We greatly appreciate your support!

If you would like to join the Weekly Space Hangout Crew, visit their site here and sign up. They’re a great team who can help you join our online discussions!

Want to support CosmoQuest? Here are specific ways you can help:

* Donate! (Streamlabs link) https://streamlabs.com/cosmoquestx

* Buy stuff from our Redbubble https://www.redbubble.com/people/cosmoquestx

* Help us find sponsors by sharing our program and fundraising efforts through your networks

* Become a Patreon of Astronomy Cast https://www.patreon.com/astronomycast

* Sponsor 365 Days of Astronomy http://bit.ly/sponsor365DoA

* A combination of the above!

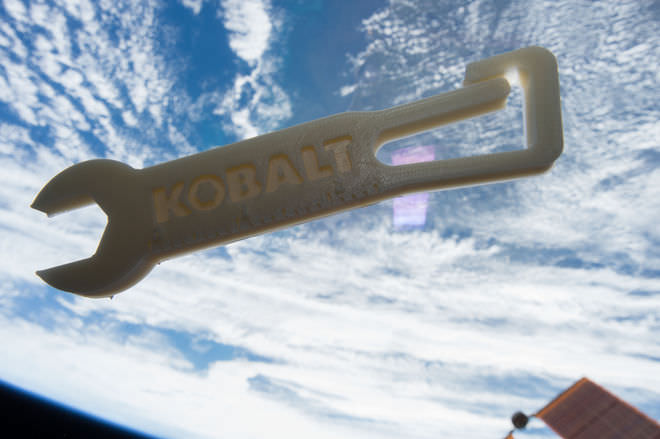

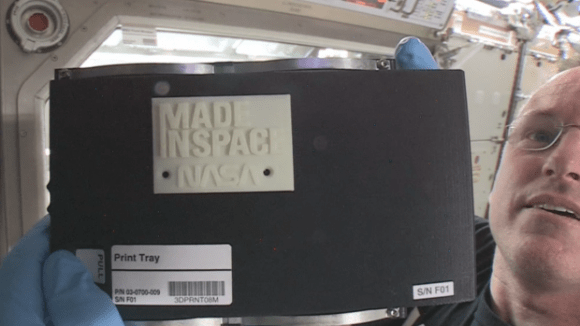

First 3D Tools Printed Aboard Space Station

Astronauts aboard the International Space Station have manufactured their first tool using the 3D printer on board the station. This is another step in the ongoing process of testing and using additive manufacturing in space. The ability to build tools and replacement parts at the station is something NASA has been pursuing keenly.

The first tool printed was a simple wrench. This may not sound like ground-breaking stuff, unless you’ve ever been in the middle of a project only to find you’re missing a simple tool. A missing tool can stop any project in its tracks, and change everybody’s plans.

The benefits of manufacturing needed items in space are obvious. Up until now, every single item needed on the ISS had to be sent up via re-supply ship. That’s not a quick turnaround. Now, if a tool is lost or destroyed during normal use, a replacement can be quickly manufactured on-site.

This isn’t the first item to be printed at the station. The first one was printed back in November 2014. That item was a replacement part for the printer itself. This was important because it showed that the machine can be used to keep itself running. This reliability is key if astronauts are going to be able to rely on the printer for manufacturing critical replacements for components and spare parts.

Niki Werkheiser, the project manager for the ISS 3D printer, said in a NASA YouTube video, “Since the inception of the human space program, we have been completely dependent on launching every single thing we need from Earth to space … I think we’re making history for the first time ever being able to make what we need when we need it in space.”

The 3D printer, which is more accurately called an Additive Manufacturing Facility (AMF) was built by a company called Made In Space. The one that was used to make the first tool is actually a different one than was used to make the replacement part for the printer itself. The first one was part of a test in 2014 to see how 3D printing would work in microgravity. It printed several items which were returned to Earth for testing. Those tests went well, which led to the second one being sent to the station.

This second machine, which was used to create the wrench, is a much more fully featured, commercial 3D printer. According to Made In Space, this newer AMF “can be accessed by any Earth-bound customer for job-specific work, like a machine shop in space. Example use cases include a medical device company prototyping space-optimized designs, or a satellite manufacturer testing new deployable geometries, or creating tools for ISS crew members.”

This is exciting news for we space enthusiasts, but even more exciting for a certain engineering student from the University of Alabama. The student, Robert Hillan, submitted a tool design to a NASA competition called the Future Engineers Space Tool design competition. The challenge was to design a tool that could be used successfully by astronauts in space. The catch was that the tool design had to upload to the ISS electronically and be printed by the AMF on the station.

In January, Hillan was announced as the winner. His design? The Multipurpose Precision Maintenance Tool, a kind of multi-tool that handy people are familiar with. The tool allows astronauts to tighten and loosen different sizes of nuts and bolts, and to strip wires.

NASA astronaut Tim Kopra, who is currently aboard the ISS, praised both Hillan and the 3D printing technology itself. “When you have a problem, it will drive specific requirements and solutions. 3-D printing allows you to do a quick design to meet those requirements. That’s the beauty of this tool and this technology. You can produce something you hadn’t anticipated and do it on short notice.”

The immediate and practical benefits of AMF in space are obvious and concrete. But like a lot of space technologies, it is part of a larger picture, too.

Werkheiser, NASA’s project manager for the ISS 3D printer, said “If a printer is critical for explorers, it must be capable of replicating its own parts, so that it can keep working during longer journeys to places like Mars or an asteroid. Ultimately, one day, a printer may even be able to print another printer.”

So there we have it. A journey to Mars and printers replicating themselves. Bring it on.

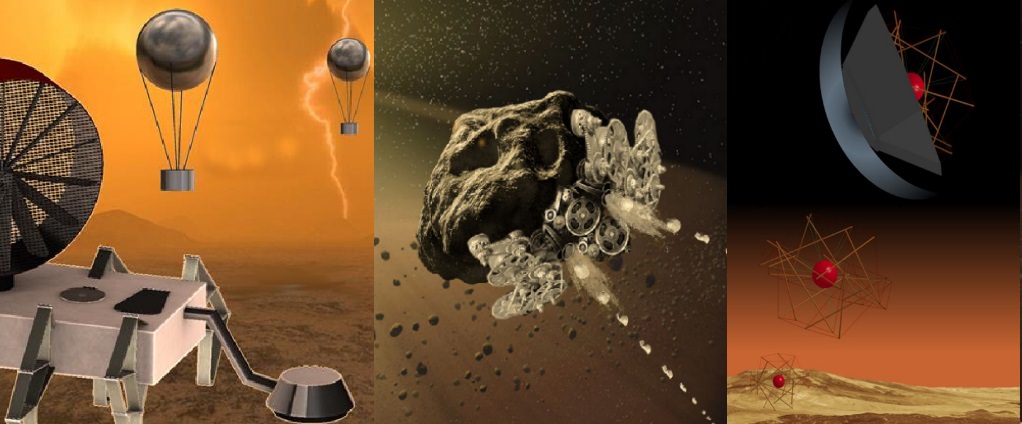

NASA Invests In Radical Game-Changing Concepts For Exploration

Every year, the NASA Innovative Advanced Concepts (NIAC) program puts out the call to the general public, hoping to find better or entirely new aerospace architectures, systems, or mission ideas. As part of the Space Technology Mission Directorate, this program has been in operation since 1998, serving as a high-level entry point to entrepreneurs, innovators and researchers who want to contribute to human space exploration.

This year, thirteen concepts were chosen for Phase I of the NIAC program, ranging from reprogrammed microorganisms for Mars, a two-dimensional spacecraft that could de-orbit space debris, an analog rover for extreme environments, a robot that turn asteroids into spacecraft, and a next-generation exoplanet hunter. These proposals were awarded $100,000 each for a nine month period to assess the feasibility of their concept.

Continue reading “NASA Invests In Radical Game-Changing Concepts For Exploration”

Moonbase by 2022 For $10 Billion, Says NASA

Returning to the Moon has been the fevered dream of many scientists and astronauts. Ever since the Apollo Program culminated with the first astronauts setting foot on the Moon on July 20th, 1969, we have been looking for ways to go back to the Moon… and to stay there. In that time, multiple proposals have been drafted and considered. But in every case, these plans failed, despite the brave words and bold pledges made.

However, in a workshop that took place in August of 2014, representatives from NASA met with Harvard geneticist George Church, Peter Diamandis from the X Prize Foundation and other parties invested in space exploration to discuss low-cost options for returning to the Moon. The papers, which were recently made available in a special issue of New Space, describe how a settlement could be built on the Moon by 2022, and for the comparatively low cost of $10 billion.

Continue reading “Moonbase by 2022 For $10 Billion, Says NASA”

Here’s The First 3-D Part Printed In Space. Where Will That Take Us Next?

Here’s the 22nd-century version of breaking the surly bonds of Earth: NASA and private company Made In Space have just collaborated on the first 3-D printed part in space, ever.

The milestone yesterday (Nov. 25) is a baby step towards off-Earth manufacturing, but the implications are huge. If these testbeds prove effective enough, eventually we can think of creating these parts in other destinations such as the Moon, or an asteroid, or even Mars.

“We look at the operation of the 3-D printer as a transformative moment, not just for space development, but for the capability of our species to live away from Earth,” stated Aaron Kemmer, CEO of Made In Space — the company that developed the printer.

There are still kinks to be worked out, however. The “part adhesion” on the tray after the piece was created had a bond that was mightier than controllers anticipated, which could mean that bonding is different in microgravity. A second calibration coupon should be created shortly as controllers make adjustments to the process.

We’ll see several of these “test coupons” manufactured in the next few months and then sent back to Earth for more detailed analysis. Meanwhile, we have two more 3-D printers to look forward to in space: one created by the Italians that should arrive while their citizen, Samantha Cristoforetti, is still on station (she just arrived a few days ago) and a second one created by Made In Space that is supposed to commercialize the process.

The idea of 3-D printing has been discussed extensively in the media by both NASA and the European Space Agency in the past year or so. ESA has released media speculating on how additive manufacturing could be used to create Moon bases at some distant date. Meanwhile, NASA has talked about perhaps creating food using a 3-D printer.

If additive manufacturing takes off, so to speak, it could reduce shipping costs from Earth to the International Space Station because controllers could just send up a set of instructions to replace a part or tool. But NASA should move quickly to test this stuff out, according to a recent National Research Council report; the station is approved for operations only until 2020 (so far), which leaves only about five years or so to do testing before agencies possibly move to other destinations.