KENNEDY SPACE CENTER, FL – After a six year lull NASA’s historic pad 39A roared back to business this morning with the dramatic maiden blastoff of a SpaceX Falcon 9 rocket, on a critical cargo delivery mission for NASA to the space station – while simultaneously landing the first stage back on the ground at the Cape on a secondary mission aimed at one day propelling humans to Mars.

The era of undesired idleness for America’s most famous launch pad was broken at last by the rumbling thunder of a SpaceX Falcon 9 that ignited at 9:38 a.m. EST Sunday morning, Feb 19, at Launch Complex 39A at NASA’s Kennedy Space Center.

The storied liftoff took place under heavily overcast skies with rain showers nearby under seemingly improbable weather conditions.

After liftoff, the rocket disappeared within seconds and never really reappeared in the local area until the final moments of the descent of the first stage – which nailed a nearly perfect dead center touchdown at Landing Zone 1 at the Cape some 9 minutes after launch.

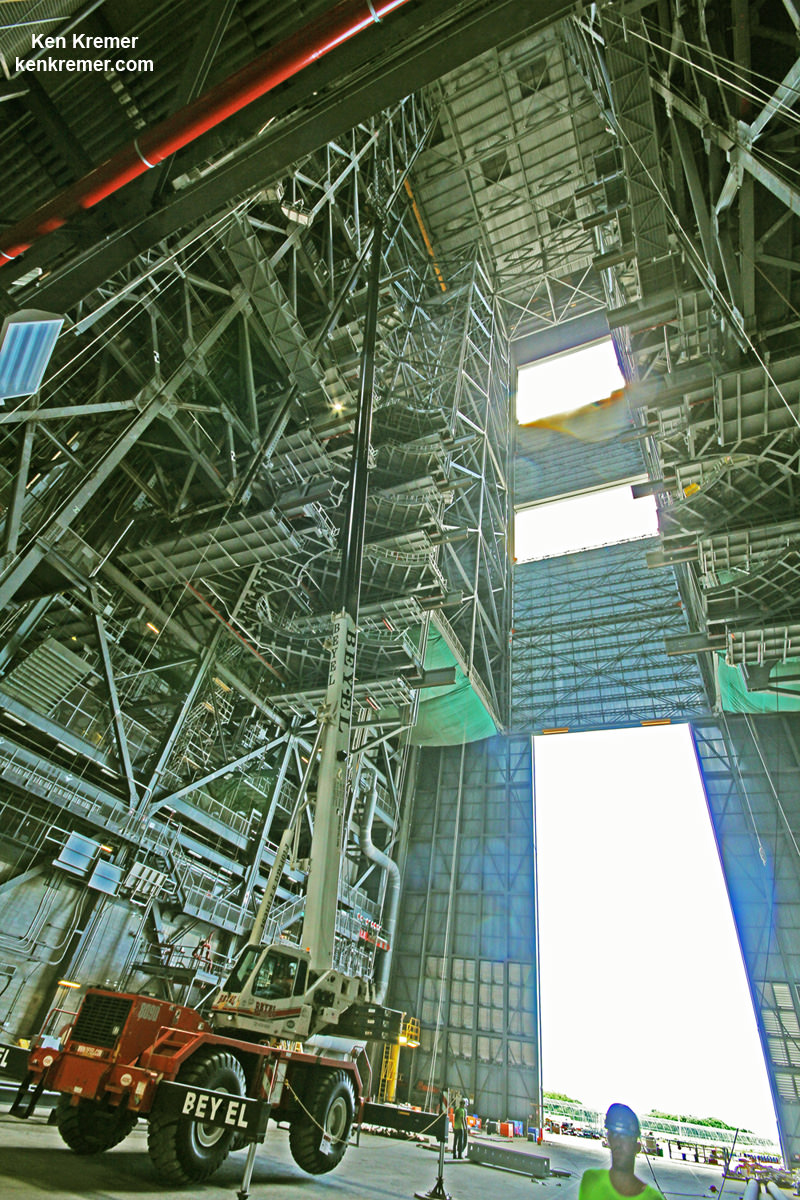

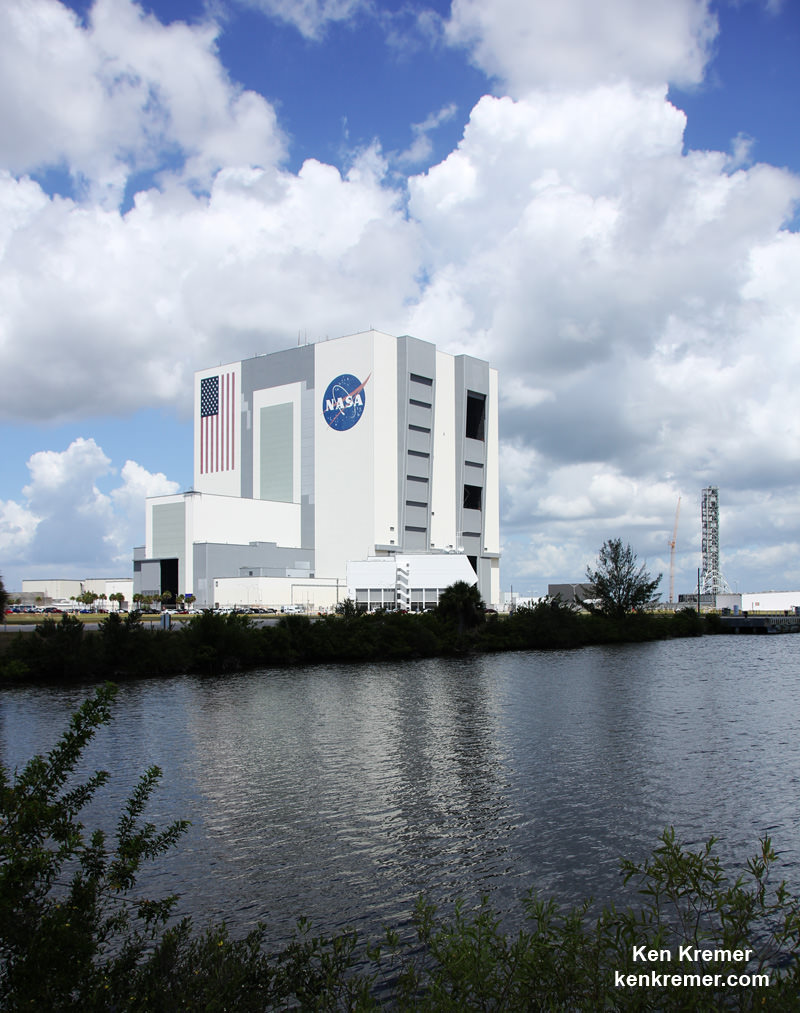

Nevertheless the Falcon 9 launch was a smashing success and probably the loudest I have ever witnessed since the shuttle era ended. Watching from atop the roof of the iconic VAB, I can report the building did experience some rather exciting rattling!

And it was SpaceX’s first daylight booster landing back at the Cape. The two earleir touchdowns were at night – most recently for the CRS-9 mission last summer in July 2016.

The goal of the mission was aimed at launching the SpaceX Dragon cargo freighter to deliver over 5500 pounds of science and supplies to the orbiting science outpost on the CRS-10 mission.

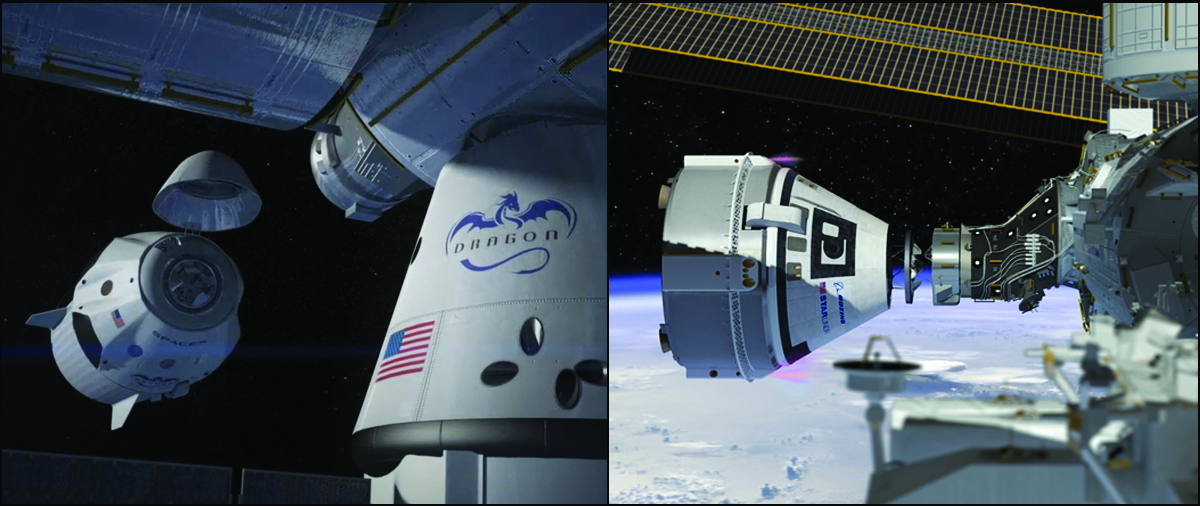

The Dragon spacecraft was successfully delivered in Earth orbit and is on course for the International Space Station (ISS) on the CRS-10 mission.

As a secondary side goal, SpaceX successfully carried out a propulsive soft landing of the 156 foot tall first stage of the Falcon 9 rocket on land at Cape Canaveral Air Force Station’s Landing Zone 1 (LZ-1), located about 9 miles south of KSC launch complex 39A.

The touchdown, like the launch was completely obscured until the final moments of the descent, when it suddenly and magnificently reappeared as a strange pale colored cylinder emitting a long yellow flame after dropping below the low hanging clouds.

The booster successfully accomplished a propulsive upright soft landing at Landing Zone-1 (LZ-1) accompanied by multiple sonic booms at Cape Canaveral Air Force Station, Florida, about 9 minutes after launch.

This was the 8th first stage booster that SpaceX has successfully recovered either by land or on a tiny droneship at sea over the past year.

The goal is to refurbish and recycle the 156 foot tall first stage boosters for relaunch with a new payload.

SpaceX CEO billionaire Elon Musk hopes that by reusing the spent booster, he can drastically cut the cost of access to space and that will one day lead to human colonies and a “City on Mars.”

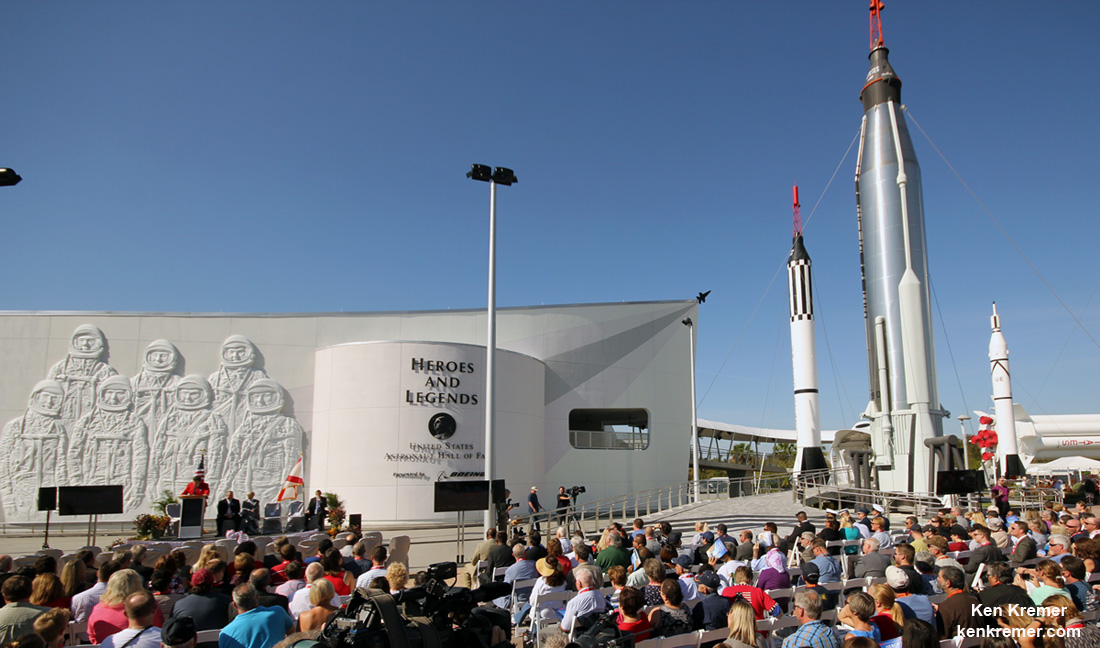

The dream of Bob Cabana, former astronaut and now Center Director at the Kennedy Space Center NASA’s, to turn KSC into a multiuser spaceport open to utilization by government, industry and entrepreneurs like SpaceX’s billionaire CEO Elon Musk is finally coming to fruition in a blaze of glory.

“I’m so proud of this team for all the dedication and hard work,” said Cabana.

Today’s launch counts as the first commercial launch from Kennedy’s historic pad.

The storied pad initially sent NASA astronauts to the Moon soon after the dawn of the Space Age during the Apollo/Saturn era and was then significantly overhauled to serve as the on ramp for NASA space shuttles for another three decades.

SpaceX has now transformed pad 39A for launches of the Falcon 9. A bright future lies ahead with launches of the heavy lift Falcon Heavy later this year and a renewal of manned launches of astronauts some time in 2018.

Dragon is carrying more than 5500 pounds of equipment, gear, food, crew supplies, hardware and NASA’s Stratospheric Aerosol Gas Experiment III (SAGE III) ozone mapping science payload in support of the Expedition 50 and 51 crew members.

SAGE III will measure stratospheric ozone, aerosols, and other trace gases by locking onto the sun or moon and scanning a thin profile of the atmosphere.

The LIS lightning mapper will measure lightning from the altitude of the ISS. NASA’s RAVEN experiment will test autonomous docking technologies for spacecraft.

The research supplies and equipment brought up by Dragon will support over 250 scientific investigations to advance knowledge about the medical, psychological and biomedical challenges astronauts face during long-duration spaceflight.

As of today we are at last launching rockets again from the Kennedy Space Center – thanks to SpaceX and the Falcon 9. What a tremendous return to space !

Watch for Ken’s onsite CRS-10 mission reports direct from the Kennedy Space Center and Cape Canaveral Air Force Station, Florida.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.

………….

Learn more about SpaceX CRS-10 launch to ISS, ULA SBIRS GEO 3 launch, EchoStar launch GOES-R launch, Heroes and Legends at KSCVC, OSIRIS-REx, InSight Mars lander, ULA, SpaceX and Orbital ATK missions, Juno at Jupiter, SpaceX AMOS-6, ISS, ULA Atlas and Delta rockets, Orbital ATK Cygnus, Boeing, Space Taxis, Mars rovers, Orion, SLS, Antares, NASA missions and more at Ken’s upcoming outreach events at Kennedy Space Center Quality Inn, Titusville, FL:

Feb 18 – 19: “SpaceX CRS-10 launch to ISS, ULA Atlas SBIRS GEO 3 launch, EchoStar 19 comsat launch, GOES-R weather satellite launch, OSIRIS-Rex, SpaceX and Orbital ATK missions to the ISS, Juno at Jupiter, ULA Delta 4 Heavy spy satellite, SLS, Orion, Commercial crew, Curiosity explores Mars, Pluto and more,” Kennedy Space Center Quality Inn, Titusville, FL, evenings