The package of powerful science instruments at the heart of NASA’s mammoth James Webb Space Telescope (JWST) have been successfully installed into the telescopes structure.

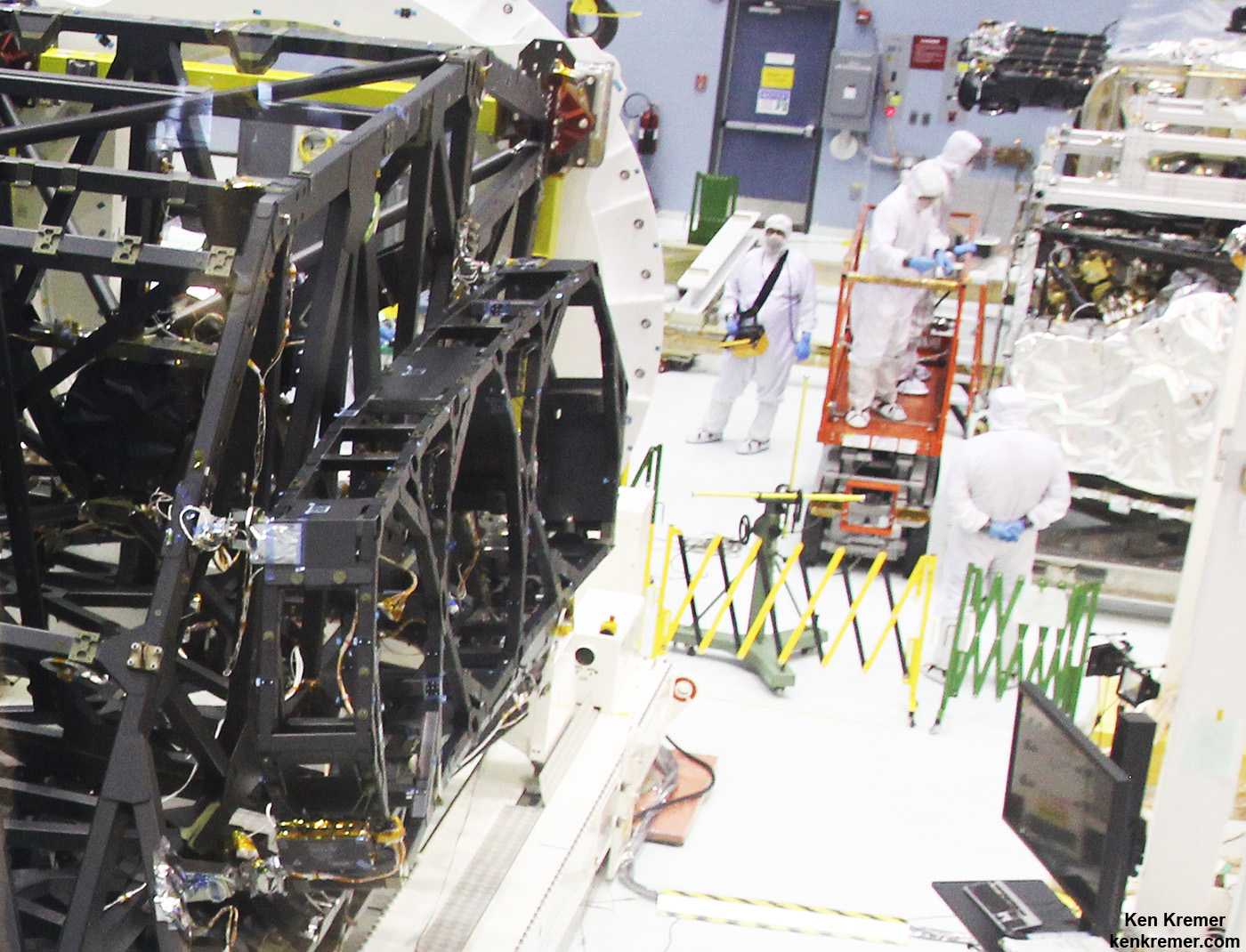

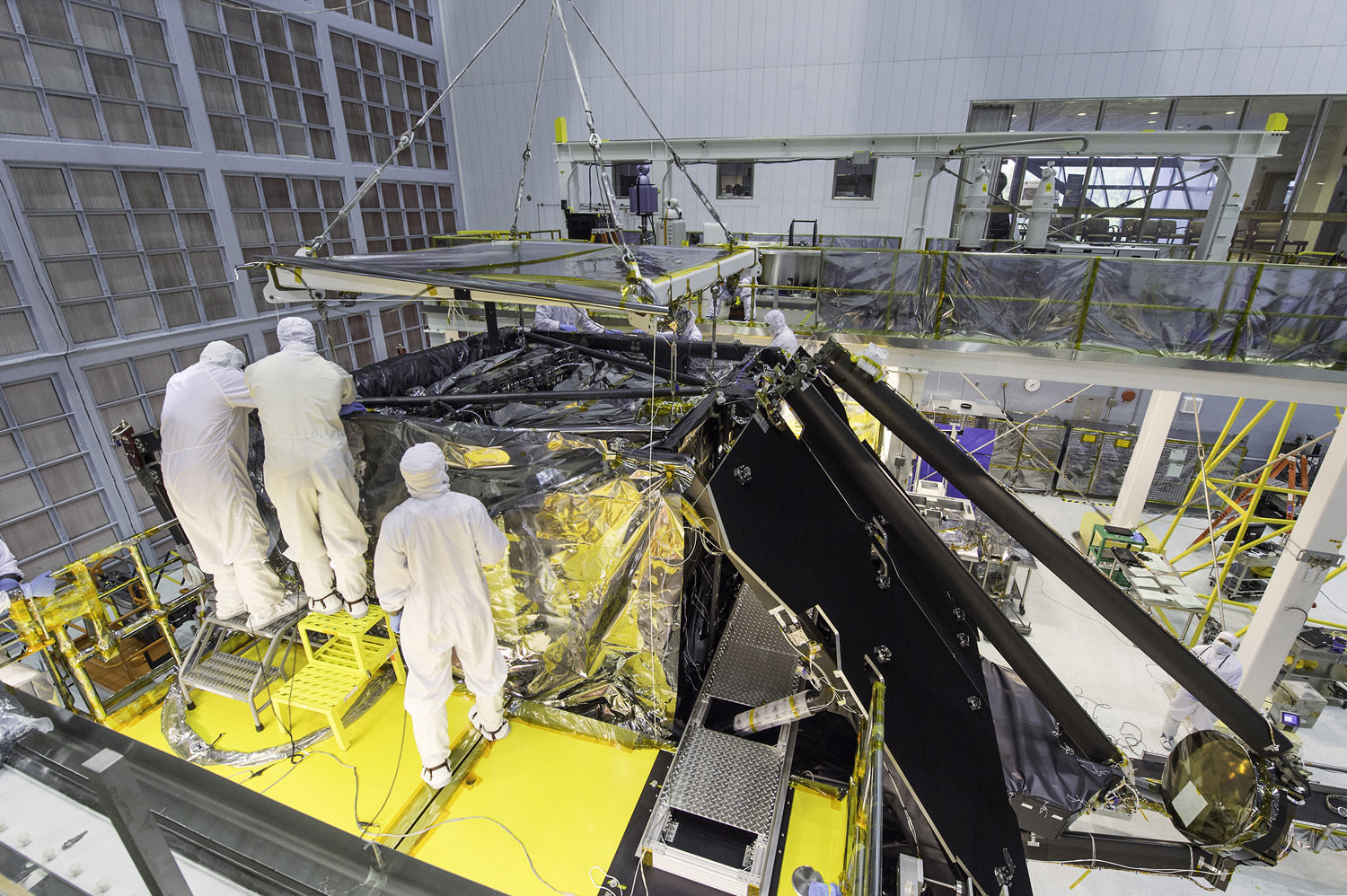

A team of two dozen engineers and technicians working with “surgical precision” inside the world’s largest clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, meticulously guided the instrument package known as the ISIM (Integrated Science Instrument Module) into the telescope truss structure.

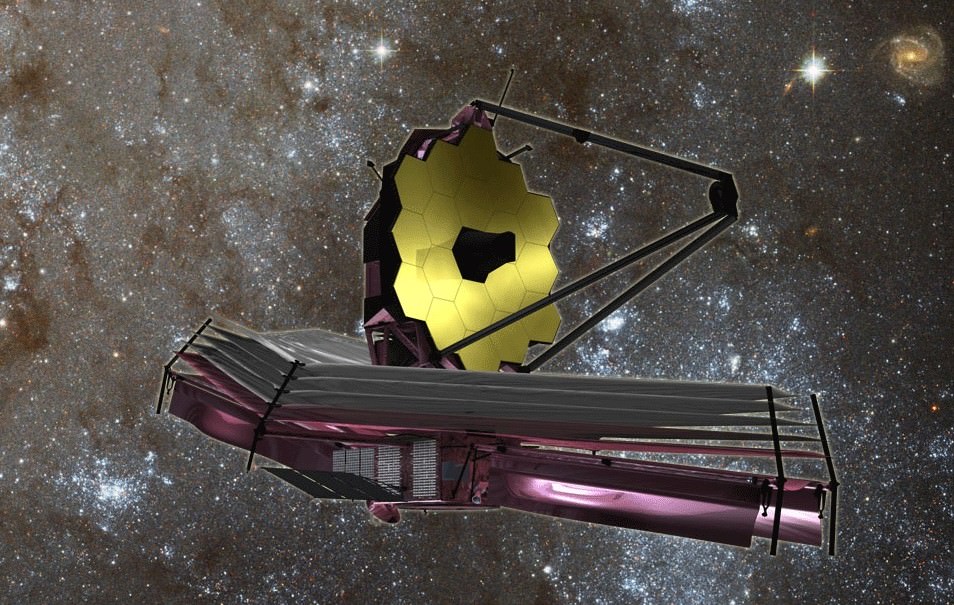

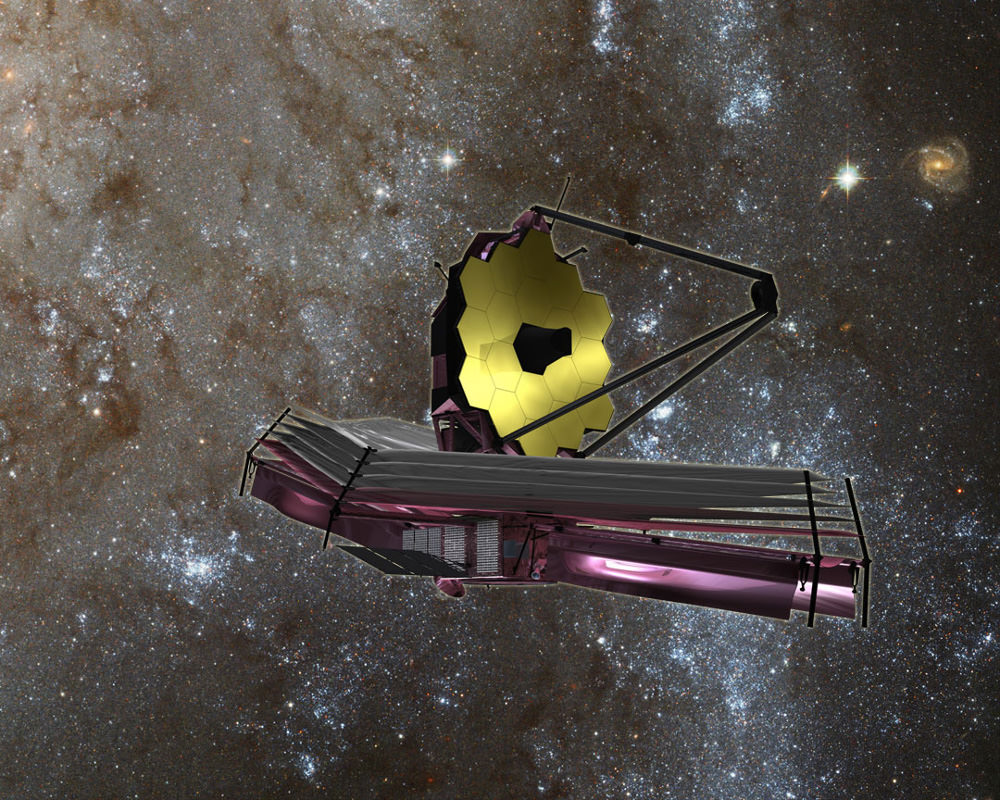

ISIM is located right behind the 6.5 meter diameter golden primary mirror – as seen in NASA’s and my photos herein.

The ISIM holds the observatory’s international quartet of state-of-the-art research instruments, funded, built and provided by research teams in the US, Canada and Europe.

“This is a tremendous accomplishment for our worldwide team,” said John Mather, James Webb Space Telescope Project Scientist and Nobel Laureate, in a statement.

“There are vital instruments in this package from Europe and Canada as well as the US and we are so proud that everything is working so beautifully, 20 years after we started designing our observatory.”

Just as with the mirrors installation and other assembly tasks, the technicians practiced the crucial ISIM installation procedure numerous times via test runs, computer modeling and a mock-up of the instrument package.

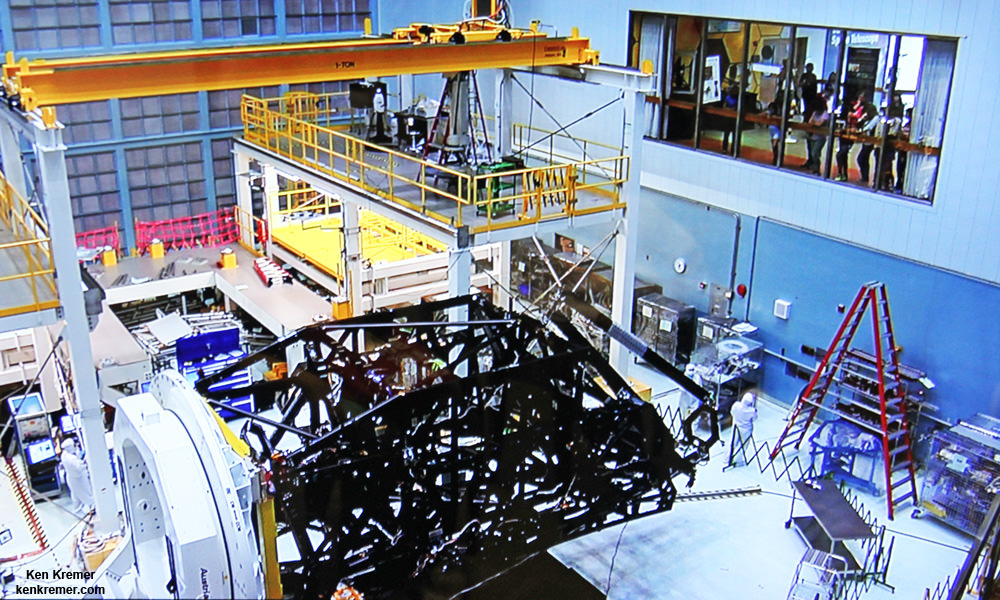

To accomplish the ISIM installation, the telescope structure had to be flipped over and placed into the giant work gantry in the clean room to enable access by the technicians.

“The telescope structure has to be turned over and put into the gantry system [in the clean room],” said John Durning, Webb Telescope Deputy Project Manager, in an exclusive interview with Universe Today at NASA’s Goddard Space Flight Center.

“Then we take ISIM and install in the back of the telescope.”

The team used an overhead crane to lift and maneuver the heavy ISIM science instrument package in the clean room. Then they lowered it into the enclosure behind the mirrors on the telescopes backside and secured it to the structure.

“Our personnel were navigating a very tight space with very valuable hardware,” said Jamie Dunn, ISIM Manager.

“We needed the room to be quiet so if someone said something we would be able to hear them. You listen not only for what other people say, but to hear if something doesn’t sound right.”

The ISIM installation continues the excellently executed final assembly phase of Webb at Goddard this year. And comes just weeks after workers finished installing the entire mirror system.

This author has witnessed and reported on the assembly progress at Goddard on numerous occasions, including after the mirrors were recently uncovered and unveiled in all their golden glory.

“The entire mirror system is checked out. The system has been integrated and the alignment has been checked,” said John Durning, Webb Telescope Deputy Project Manager, in an exclusive interview with Universe Today at NASA’s Goddard Space Flight Center.

ISIM is a collection of cameras and spectrographs that will record the light collected by Webb’s giant golden primary mirror.

“It will take us a few months to install ISIM and align it and make sure everything is where it needs to be,” Durning told me.

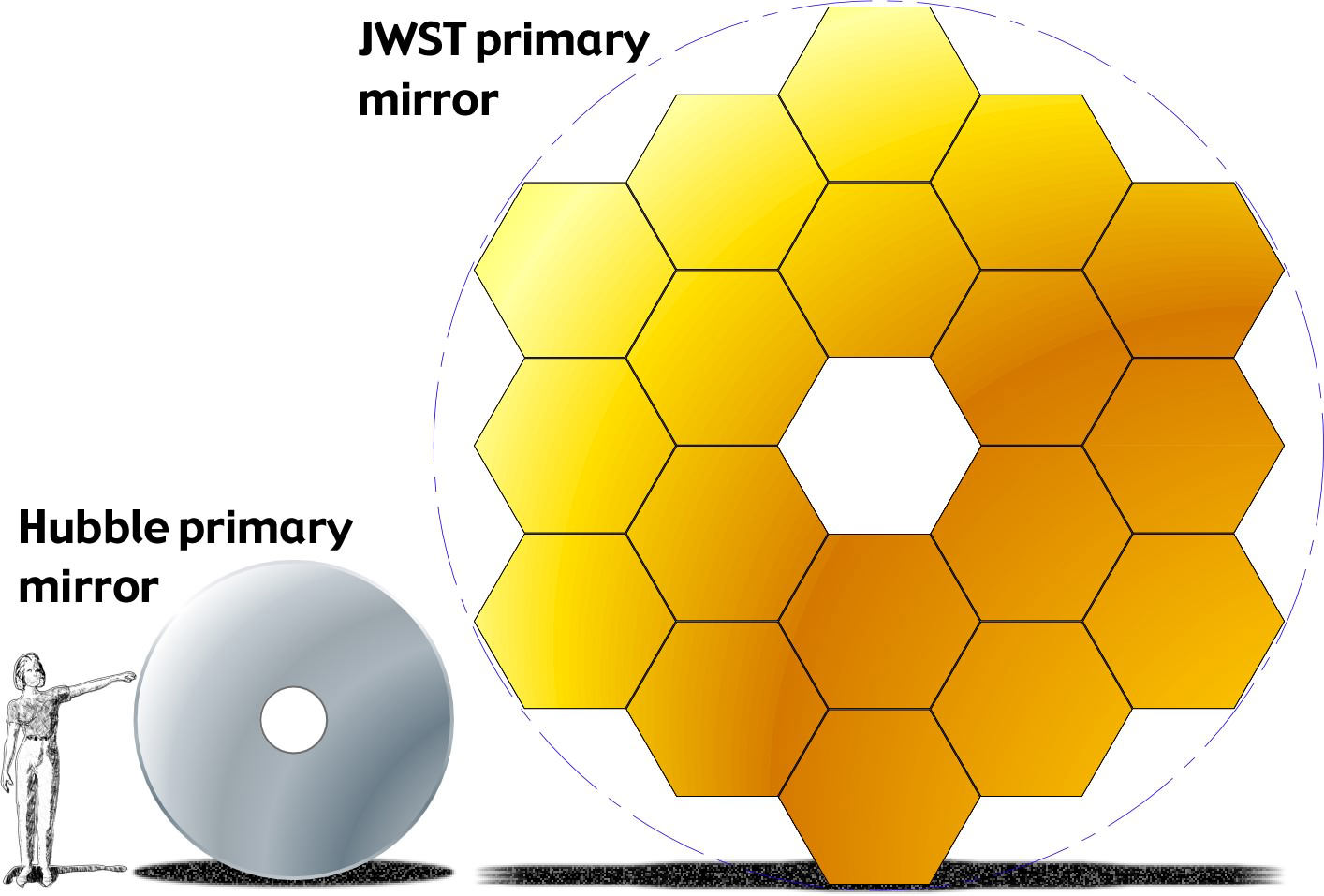

The primary mirror is comprised of 18 hexagonal segments.

Each of the 18 hexagonal-shaped primary mirror segments measures just over 4.2 feet (1.3 meters) across and weighs approximately 88 pounds (40 kilograms). They are made of beryllium, gold coated and about the size of a coffee table.

Webb’s golden mirror structure was tilted up for a very brief period on May 4 as seen in this NASA time-lapse video:

The 18-segment primary mirror of NASA’s James Webb Space Telescope was raised into vertical alignment in the largest clean room at the agency’s Goddard Space Flight Center in Greenbelt, Maryland, on May 4, 2016. Credit: NASA

The gargantuan observatory will significantly exceed the light gathering power of NASA’s Hubble Space Telescope (HST) – currently the most powerful space telescope ever sent to space.

With the mirror structure complete, the next step was the ISIM science module installation.

To accomplish that installation, technicians carefully moved the Webb mirror structure into the clean room gantry structure.

As shown in this time-lapse video we created from Webbcam images, they tilted the structure vertically, flipped it around, lowered it back down horizontally and then transported it via an overhead crane into the work platform.

Time-lapse showing the uncovered 18-segment primary mirror of NASA’s James Webb Space Telescope being raised into vertical position, flipped and lowered upside down to horizontal position and then moved to processing gantry in the largest clean room at the agency’s Goddard Space Flight Center in Greenbelt, Maryland, on May 4/5, 2016. Images: NASA Webbcam. Time-lapse by Ken Kremer/kenkremer.com/Alex Polimeni

The telescope will launch on an Ariane V booster from the Guiana Space Center in Kourou, French Guiana in 2018.

The Webb Telescope is a joint international collaborative project between NASA, the European Space Agency (ESA) and the Canadian Space Agency (CSA).

Webb is designed to look at the first light of the Universe and will be able to peer back in time to when the first stars and first galaxies were forming. It will also study the history of our universe and the formation of our solar system as well as other solar systems and exoplanets, some of which may be capable of supporting life on planets similar to Earth.

More about ISIM and upcoming testing in the next story.

Watch this space for my ongoing reports on JWST mirrors, science, construction and testing.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.