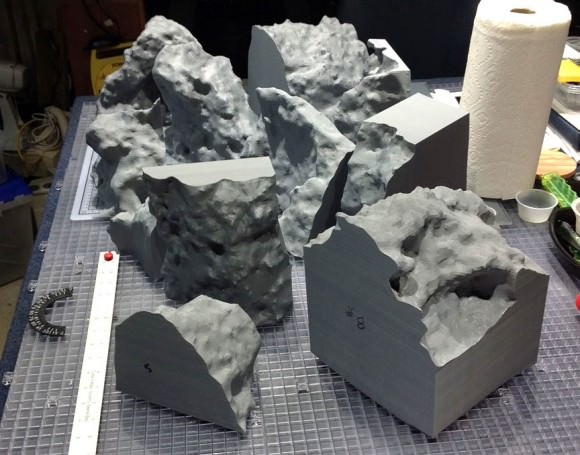

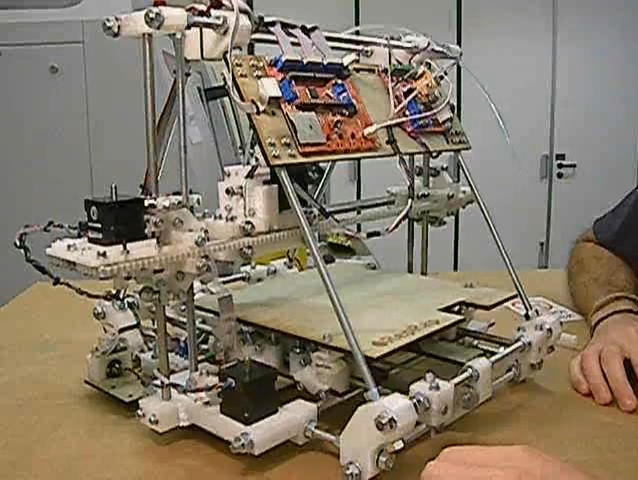

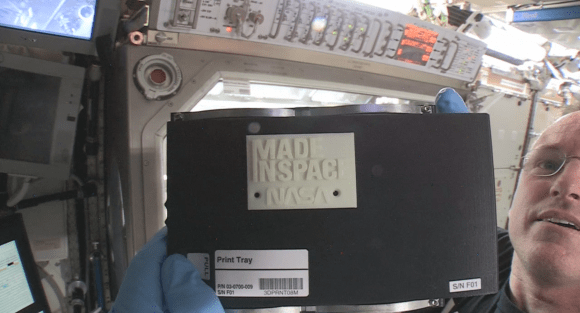

In the 1960s, we thought the best way of sending stuff between Earth and space was through a transporter. These days, turns out all it takes is an e-mail and a special 3-D printer. The first tool created in space, a rachet, was made last week on the International Space Station using plans beamed from Earth. Now, we get to see if it actually works.

The printer has been active for a few weeks, making test items that had already been done on Earth. But for this particular item, manufacturer Made In Space chose to take an additional risk: creating a tool from plans that were done almost at the last minute, similar to how a real mission would work when astronauts have a sudden need for a part.

“Made In Space uplinked a design which did not exist when the printer was launched. In fact the ratchet was designed, qualified, tested, and printed in space in less than a week,” the company wrote on its blog.

And it wasn’t as simple as just sending up the plans and hoping for the best. NASA had to give the safety thumbs-up before it went up there. Also, the plans (once sent to the space station) were verified as okay to go by Made In Space engineers before the crew got the okay to print last week.

The rachet took about four hours to print in space, which is a heck of a lot faster than sitting around waiting for a cargo ship — especially when said ship is delayed, as what happened recently to the SpaceX Dragon that was supposed to launch on Friday (Dec. 19) and has now been pushed back to at least Jan. 6.

While the rachet could be of use for simple repairs in space, it won’t be staying up there long. Just as with all the other parts printed so far, it’s going to be sent back to Earth for analysis to make sure it can stand up to the rigors of a space mission. Made In Space will soon have a more robust printer going up to station, and wants to make sure all the kinks are worked out before then.

Source: Made In Space