Multiple space agencies are looking to the Moon as a future destination for exploration and development. This will include the creation of permanent infrastructure that will enable regular crewed missions and possibly future settlers. It is also hoped that this infrastructure will lead to regular missions to Mars, which could also lead to a regular human presence there. These plans require robust and innovative construction materials that can endure the harsh Lunar and Martian conditions.

These include extreme temperature variations, the near vacuum of space, radiation, and micrometeoroid impacts. To meet these requirements, a team of researchers from the University of Texas at Dallas (UT Dallas) proposes using "self-healing concrete"—aka. "bio-concrete." This material, inspired by biological processes, consists of bricks fabricated with the help of bacteria that regenerate themselves over time. Combined with lunar regolith, self-healing concrete could enable long-duration research stations and habitats on the lunar surface.

The study was led by Shruti Panda and Jacob T. Peña, a neuroscience researcher and a biomedical engineering senior (respectively) at UT Dallas. They were joined by a team of UT Dallas researchers, including Dr. Kelli Palmer-the Cecil H. and Ida Green Chair in Systems Biology Science and the Department of Biological Sciences. As they explain in their paper, bio-concrete utilizes a mold, biomineralization, and calcium carbonate crystal formation to create a durable and self-healing product.

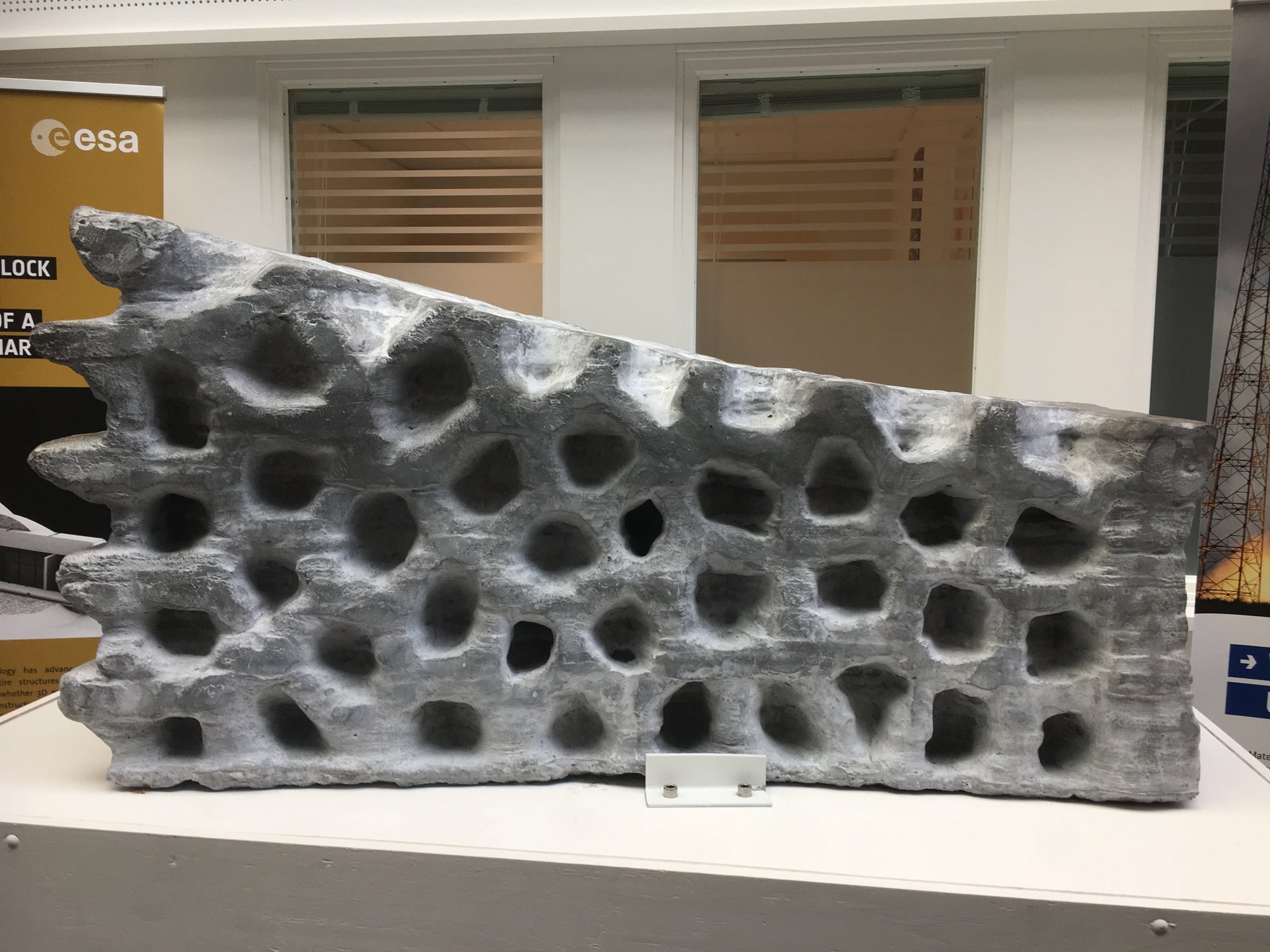

NASA and various research institutes are investigating mycelium fiber for applications in space exploration. This includes using mycelium to build tough, heat-resistant, and environmentally friendly satellites that would reduce the threat of space debris and the environmental risks associated with satellites burning up in Earth's atmosphere. In addition, NASA has been researching mycelium as a potential alternative to building materials like concrete for building habitats on the Moon and Mars.

NASA and various research institutes are investigating mycelium fiber for applications in space exploration. This includes using mycelium to build tough, heat-resistant, and environmentally friendly satellites that would reduce the threat of space debris and the environmental risks associated with satellites burning up in Earth's atmosphere. In addition, NASA has been researching mycelium as a potential alternative to building materials like concrete for building habitats on the Moon and Mars.

As Panda and Peña told Universe Today via email, bio-concrete also presents many advantages for lunar construction:

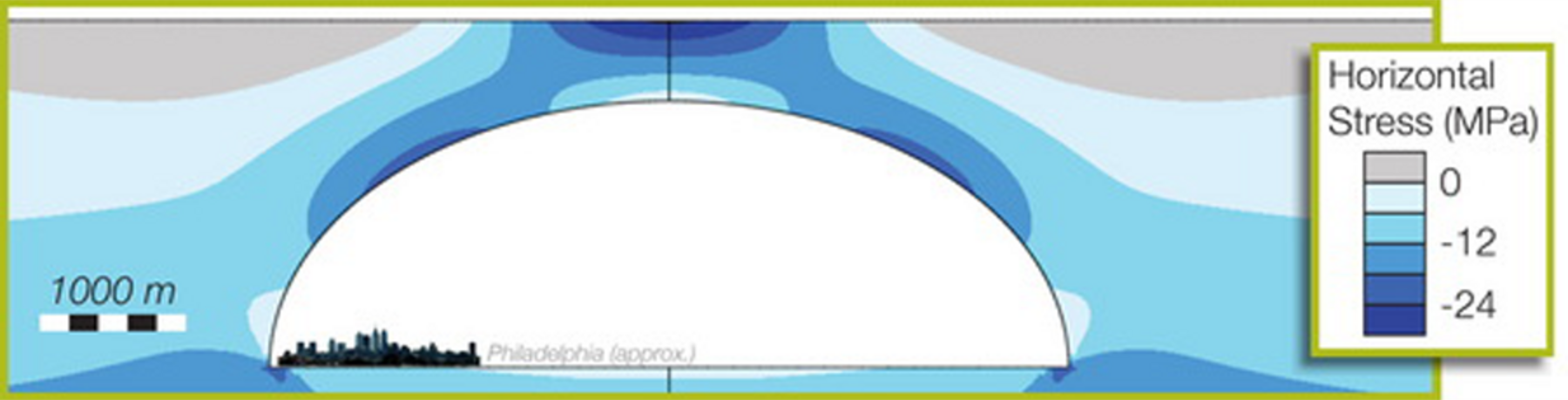

Considering the heightened durability and strength of bio-concrete, along with its decreased recovery time, the application of such a structure to the harsh conditions of the Moon may allow for enhanced longevity of lunar structures.

These harsh conditions include extreme temperature variations, elevated radiation, the vacuum of space, and micrometeoroid impacts. There's also the lunar day and night cycle in the polar regions, which consists of 14 days of continuous light followed by 14 days of dark. In a previous article, one of the concepts submitted to the 2025 LPSC proposed combining mycelium fiber with inflatable structures to create durable structures on the Moon.

For their study, Panda and Peña evaluated bio-concrete fashioned from bacteria lunar soil simulant. Previous studies have focused on using lunar regolith as an in-situ material to build structures on the lunar surface. However, adding specific bacteria to withstand the lunar environment could strengthen bricks fashioned from lunar regolith and prevent degradation. This is consistent with Section 12: Materials, Structures, Mechanical Systems, and Manufacturing of the 2024 NASA Technology Taxonomy report.

As they describe in their paper, their tests of the relative strength of lunar bio-concrete consisted of three steps: finding the right bacteria and creating spores, creating bricks encasing them, and in-situ testing. The team considered 13 different types of bacteria derived from a reef system, which were rendered into pellet form. As Panda and Peña explained:

As they describe in their paper, their tests of the relative strength of lunar bio-concrete consisted of three steps: finding the right bacteria and creating spores, creating bricks encasing them, and in-situ testing. The team considered 13 different types of bacteria derived from a reef system, which were rendered into pellet form. As Panda and Peña explained:

"Nine bacterial strains, prescreened by genetic sequencing to be from spore-forming genera and four seawater consortia were cultured in artificial reef media using instant ocean reef with added nutrients and a calcium source. The bacterial strainBacillus toyonensiswas chosen due to its ability to sporulate and produce bio-concrete, as well as its high tolerance in extreme environments."

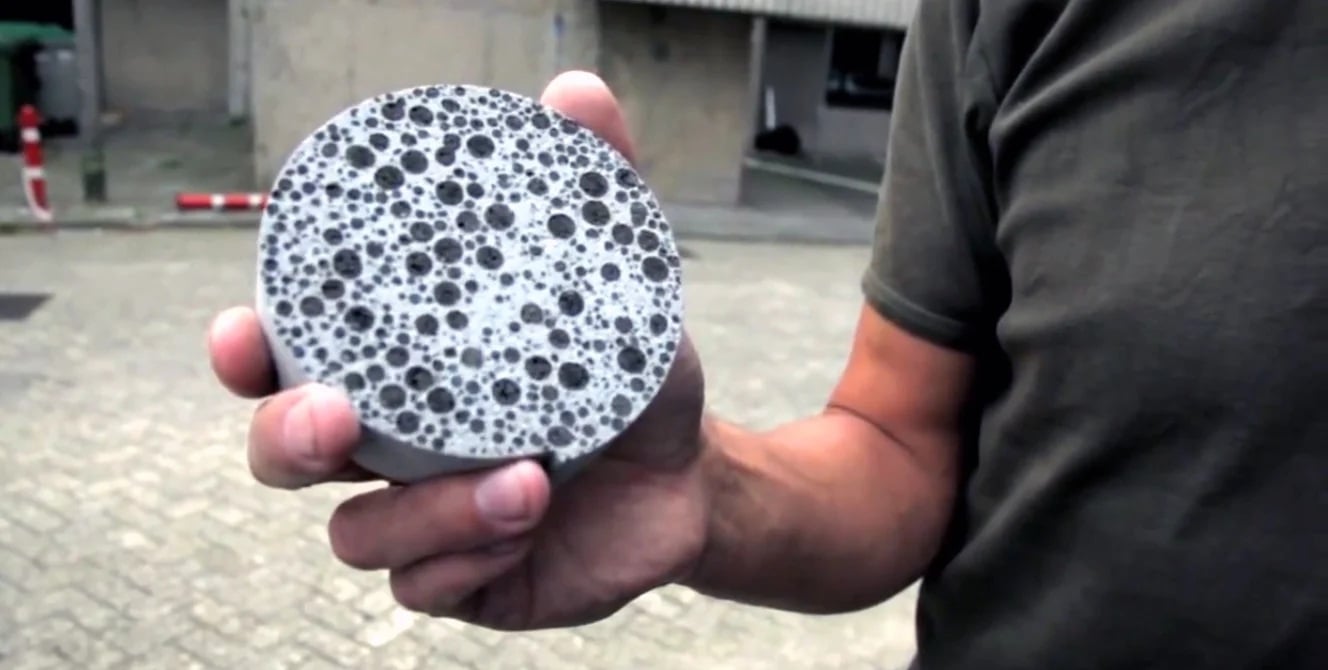

After isolating and selecting this strain of bacteria, Panda and Peña used artificial sea media containing manganese sulfate to cultureB. toyonensisfor sporulation. The pellets formed from these cultures were then aspirated, washed, and dried for two days. They were then weighed and quantified for the amount of bio-concrete they could produce. They were then coated with carbon and observed using Scanning Electron Microscopy (SEM) and visualized using phase-contrast microscopy.

They then fashioned bricks using a combination of resin, a curing agent, and pellets of the bacteria with lunar soil simulant, nutrients, yeast extract, and calcium lactate. The mixture was then poured into the molds, left for 57 minutes to gel, and cured for 3 weeks at 25 ℃ (room temp) in a fume hood. They also created a "control bricks" group composed of lunar soil simulant and no bacteria. Their results indicated that bio-concrete bricks were more effective at self-healing and suited for lunar conditions.

Looking ahead, Panda and Peña plan to conduct tests consisting of a traditional concrete control group and three experimental groups to isolate any additional factors. These will consist of traditional concrete with bacteria, concrete with lunar soil simulant and no bacteria, and lunar soil simulant and bacteria. The tests will include an analysis ofB. toyonensis'ability to spore during the concrete manufacturing process, its compression strength, and its ability to withstand radiation. As Panda and Peña emphasized:

Looking ahead, Panda and Peña plan to conduct tests consisting of a traditional concrete control group and three experimental groups to isolate any additional factors. These will consist of traditional concrete with bacteria, concrete with lunar soil simulant and no bacteria, and lunar soil simulant and bacteria. The tests will include an analysis ofB. toyonensis'ability to spore during the concrete manufacturing process, its compression strength, and its ability to withstand radiation. As Panda and Peña emphasized:

With further testing, particularly regarding the impact radiation may have on endospores and bacteria, the feasibility of this material within practical use could be more robustly understood. More quantitative concrete testing such as air permeability tests using a Torrent device, loading procedure test with a larger sample and an ultrasonic pulse velocity test can be conducted for further evaluation of bio-concrete usage on the Moon.

Further Reading:USRA

Universe Today

Universe Today