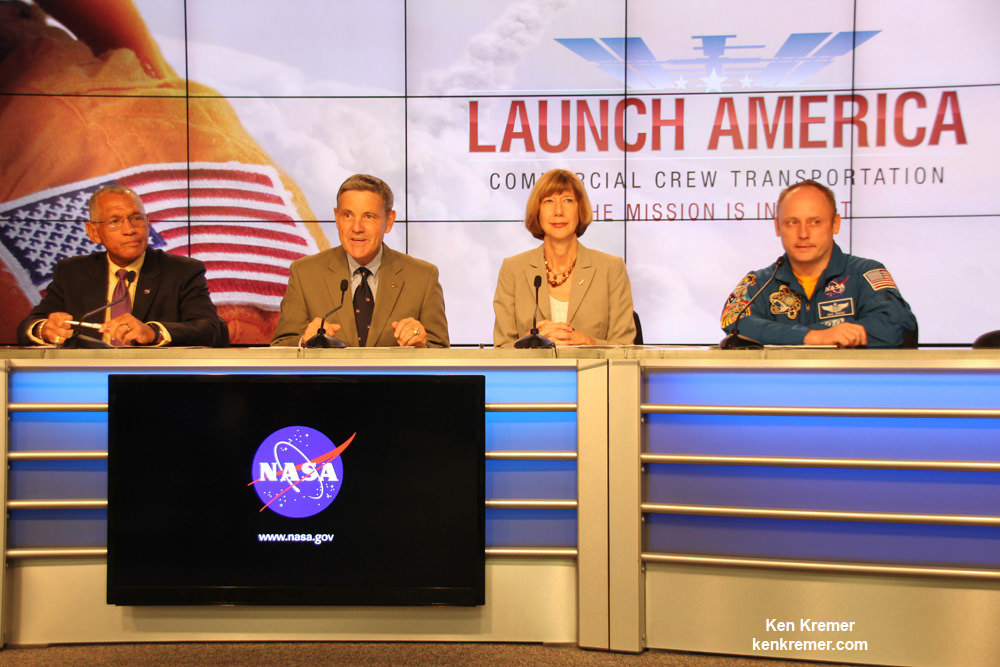

KENNEDY SPACE CENTER VISITOR COMPLEX, FL – In a moving ceremony, a pair of veteran NASA astronauts – Michael Foale and Ellen Ochoa – who once flew together on a space shuttle mission, were inducted into the U. S. Astronaut Hall of Fame at the Kennedy Space Center Visitor Complex, Florida, on May 19.

Between them, Foale and Ochoa flew to space a combined total of ten times – 6 for Foale and 4 for Ochoa.

They flew together as crewmates on the STS-56 space shuttle mission aboard Space Shuttle Discovery which launched from the Kennedy Space Center, Florida, on 8 April 1993.

The nine day STS-56 mission was Ochoa’s rookie flight and Foale’s second flight. It was the second of the shuttle’s ATLAS series of Earth science missions – dubbed Atlas-2 – whose purpose was to study the atmosphere and solar interactions.

“I was so happy to hear he and I were going to be inducted together,” Ochoa said during her acceptance speech. “He’d already had one mission and he passed along all kinds of helpful information that helped a rookie like me know where to focus and hopefully not be too surprised when the flight happened. Because being surprised in space is really not a good thing, as Mike found out.”

Ellen Ochoa counts as the first Hispanic woman to travel to space and currently serves as the 11th director of NASA’s Johnson Space Center in Houston.

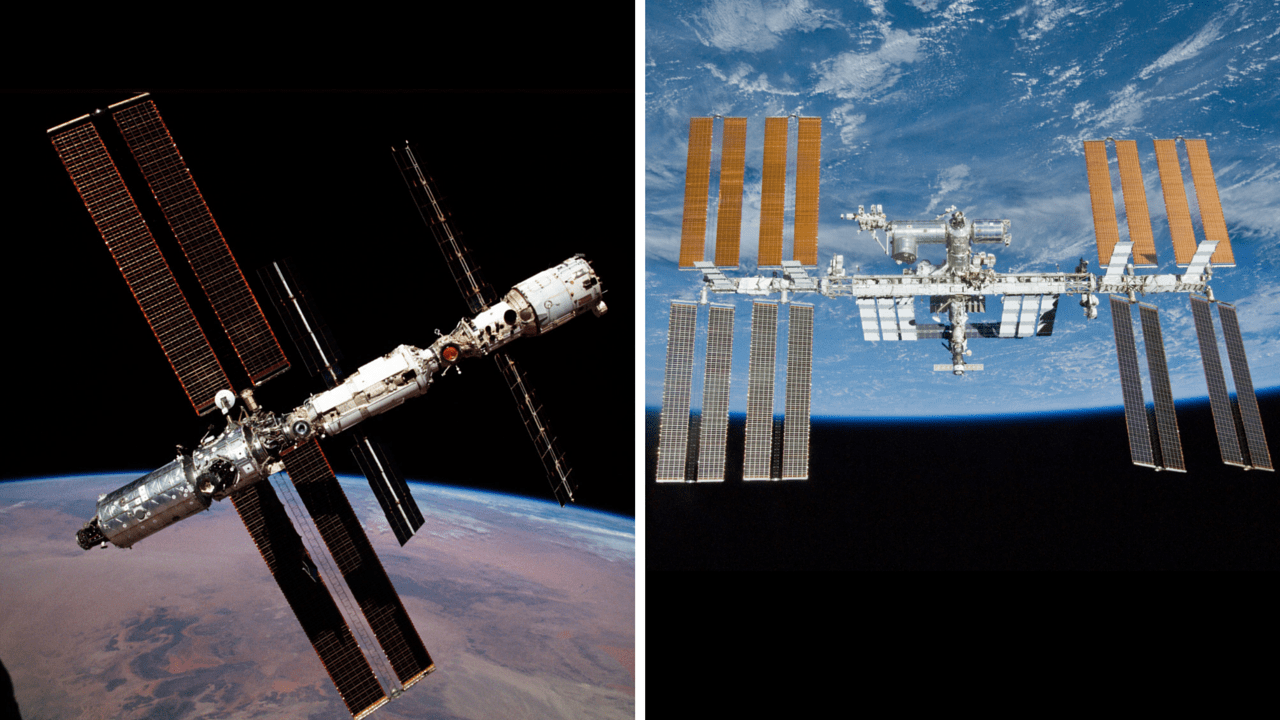

Michael Foale counts as the only U.S. astronaut to serve on both the International Space Station (ISS) and Russian space station Mir.

Foale was on board Mir in June 1997 during one of the worst disasters in space when an out of control unmanned Russian Progress cargo ship collided with the station’s Spektr module causing its air depressurization and sent Mir tumbling and rolling. He and his two Russian crewmates rapidly went into action to seal the leak, to stabilize and save Mir and themselves. He spent four months on Mir during the Mir 23 and Mir 24 missions.

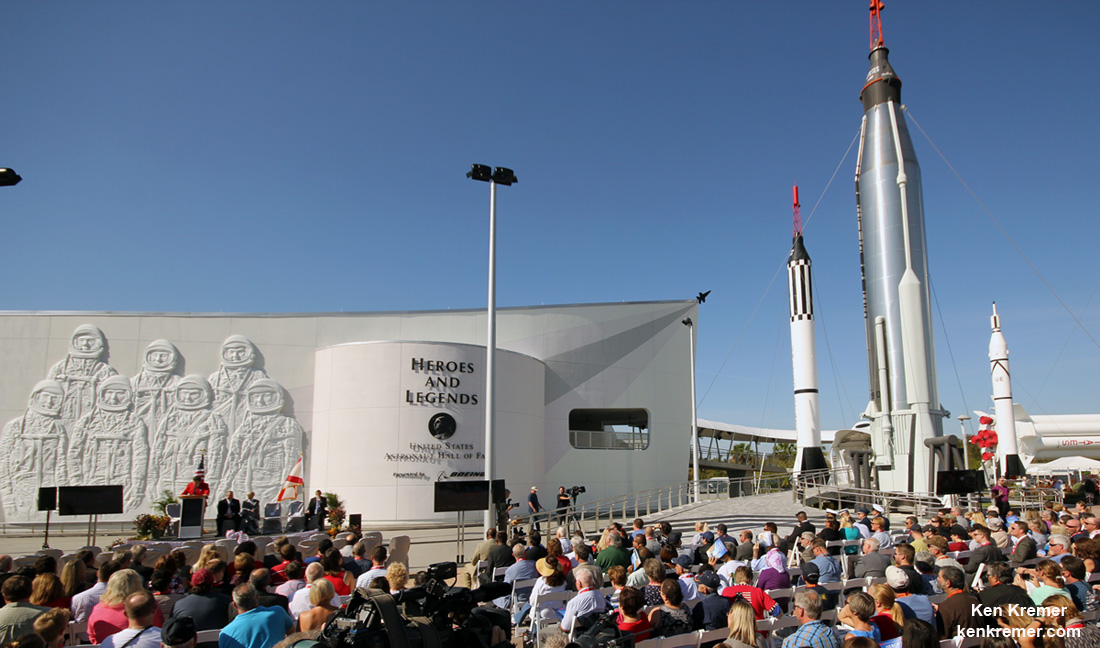

The induction ceremony was held in a truly magnificent setting below NASA’s retired Space Shuttle Atlantis orbiter now on permanent display in a dedicated pavilion at the Kennedy Space Center Visitor Complex in Florida.

Ochoa and Foale joined the ranks of 93 prestigious American space heroes who have previously received the same honor over the years since the U. S. Astronaut Hall of Fame was established in its current incarnation more than 30 years ago by the founders of the Astronaut Scholarship Foundation, the six surviving Mercury 7 astronauts.

The new duo comprise the 16th group of space shuttle astronauts to be inducted into the Hall of Fame.

Thus the Astronaut Hall of Fame now numbers 95 heroic and famous space explorers.

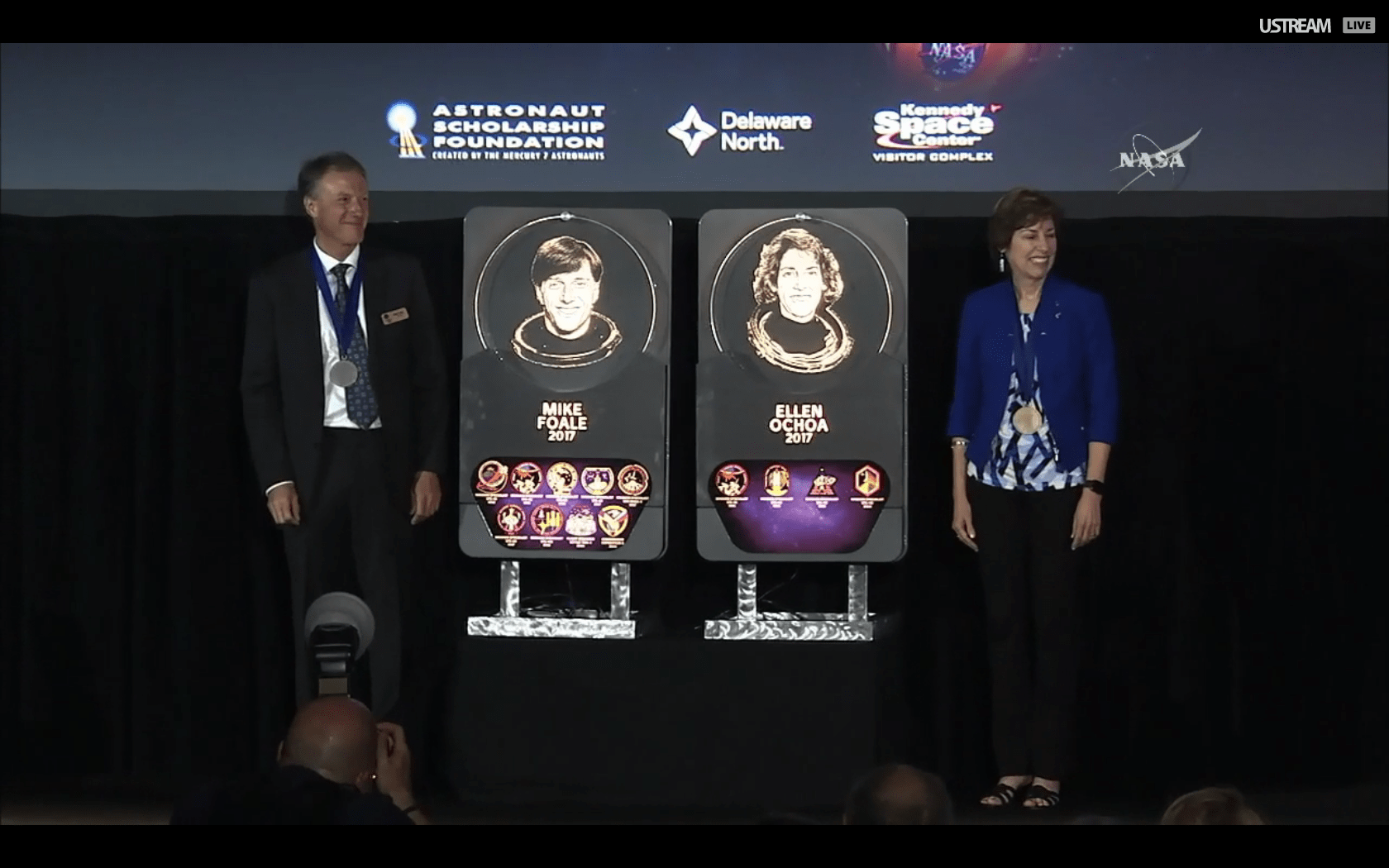

Foale and Ochoa unveiled their new ‘Hall of Fame’ commemorative plaques during the ceremony.

The plaques will be put on public display for all to see where they will join the others at the new U.S. Astronaut Hall of Fame (AHOF) pavilion – which had its Grand Opening in November 2016 as part of the new Heroes & Legends attraction located at the entrance to the Kennedy Space Center Visitor Complex.

The Astronaut Scholarship Foundation has awarded more than $4 million in merit-based scholarships to more than 400 brilliant students since its inception.

Some 21 legendary NASA astronauts were on hand for the induction ceremony, including: Robert Cabana, Dan Brandenstein, Al Worden, Charlie Duke, Karol “Bo” Bobko, Brian Duffy, Scott Altman, Michael Bloomfield, Charles Bolden, Ken Bowersox, Curtis Brown, Michael Coats, Robert Crippen, Sam Durrance, Robert Gibson, Fred Gregory, Rhea Seddon, Brewster Shaw, Loren Shriver, Kathryn Thornton, and James Wetherbee.

Here is a description of their space flight accomplishments from NASA:

“Ochoa joined NASA in 1988 as a research engineer at NASA’s Ames Research Center in California after earning a doctorate in electrical engineering from Stanford University. She joined Johnson in 1990, when she was selected as an astronaut candidate. After completing astronaut training, she served on the nine-day STS-56 mission aboard the space shuttle Discovery in 1993, conducting atmospheric studies to better understand the effect of solar activity on Earth’s climate and environment.

Ochoa has flown in space four times, including the STS-66, STS-96 and STS-110 missions, logging nearly 1,000 hours in orbit. She is Johnson’s first Hispanic director and its second female director. She also has served as the center’s deputy director and director of Flight Crew Operations.”

“Foale, whose hometown is Cambridge, England, earned a doctorate in laboratory astrophysics from the University of Cambridge, Queens’ College. A naturalized U.S. citizen, Foale was selected as an astronaut candidate in June 1987. Before his first spaceflight, he tested shuttle flight software in the Shuttle Avionics Integration Laboratory simulator.

Foale was a crew member on six space missions, including STS-45, STS-56, STS-63, STS-84, STS-103 and Soyuz TMA-3. During STS-84, he helped reestablish the Russian Space Station Mir after it was degraded by a collision and depressurization. Foale logged more than 374 days in space, including four spacewalks totaling 22 hours and 44 minutes.

Foale also served as chief of the Astronaut Office Expedition Corps, assistant director (technical) of Johnson, and deputy associate administrator for exploration operations at NASA Headquarters in Washington. His last assignment at Johnson was as chief of the Soyuz Branch, Astronaut Office, supporting Soyuz and International Space Station operations and space suit development. Foale retired from NASA in 2013.”

Read this description of the U.S. Astronaut Hall of Fame Induction Process and Eligibility:

“Each year, inductees are selected by a committee of Hall of Fame astronauts, former NASA officials, flight directors, historians and journalists. The process is administered by the Astronaut Scholarship Foundation. To be eligible, an astronaut must have made his or her first flight at least 17 years before the induction. Candidates must be a U.S. citizen and a NASA-trained commander, pilot or mission specialist who has orbited the earth at least once.”

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.