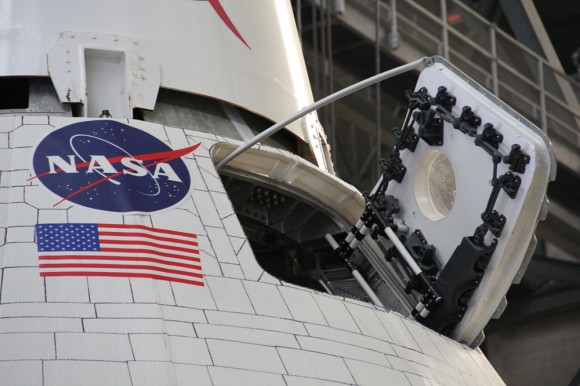

Technicians work inside the Orion crew module being built at Kennedy Space Center to prepare it for its first power on. Turning the avionics system inside the capsule on for the first time marks a major milestone in Orion’s final year of preparations before its first mission, Exploration Flight Test 1. Credit: Lockheed Martin

Story and imagery updated[/caption]

KENNEDY SPACE CENTER, FL – Orion, the first NASA spaceship that will ever carry Earthlings to deep space destinations, has at last been “powered on” for the first time at the manufacturing facility at the Kennedy Space Center (KSC) where it’s the centerpiece of a beehive humming 24/7 with hi tech processing activities in all directions.

“Power On” marks a major milestone ahead of the maiden space bound Orion test flight dubbed “EFT-1” – now at T-Minus 1 year and counting!

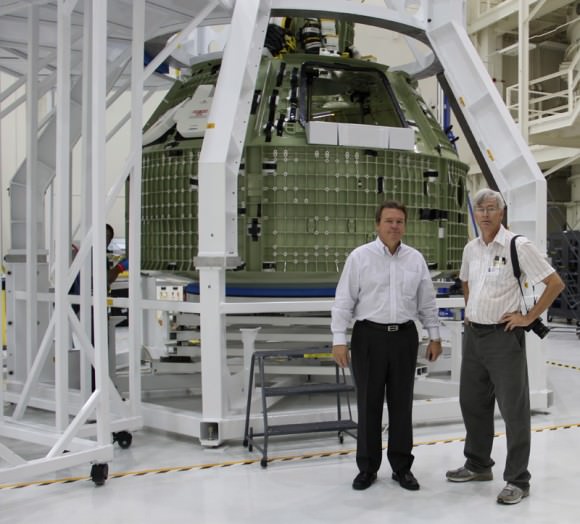

NASA and prime contractor Lockheed Martin recently granted Universe Today an exclusive in depth inspection tour of the impressive Orion EFT-1 crew module, service module and associated hardware destined for the crucial unmanned test flight slated for liftoff from Cape Canaveral in September 2014.

“We are moving fast!” said Jules Schneider, Orion Project manager for Lockheed Martin at KSC, during an exclusive interview with Universe Today as we spoke beside the Orion EFT-1 spacecraft inside the clean room.

“We are bringing Orion to life. Lots of flight hardware has now been installed.”

“We are working 24 hours a day, 7 days a week,” Schneider told me.

Some 200 people are actively employed on building Orion by Lockheed Martin at the Kennedy Space Center.

“There are many significant Orion assembly events ongoing this year,” said Larry Price, Orion deputy program manager at Lockheed Martin, in an interview with Universe Today at Lockheed Space Systems in Denver.

“This includes the heat shield construction and attachment, power on, installing the plumbing for the environmental and reaction control system, completely outfitting the crew module, attached the tiles, building the service module and finally mating the crew and service modules (CM & SM),” Price told me.

Orion is a state of the art crew capsule that will ultimately enable astronauts to fly to deep space destinations including the Moon, Asteroids, Mars and beyond – throughout our solar system.

And Universe Today has had a front row seat.

I have been very fortunate to periodically visit Orion up close over the past year and half to evaluate the testing and assembly progress inside the Operations and Checkout Building at KSC where the vehicle is now rapidly coming together, since the bare bones pressure vessel arrived to great fanfare in June 2012.

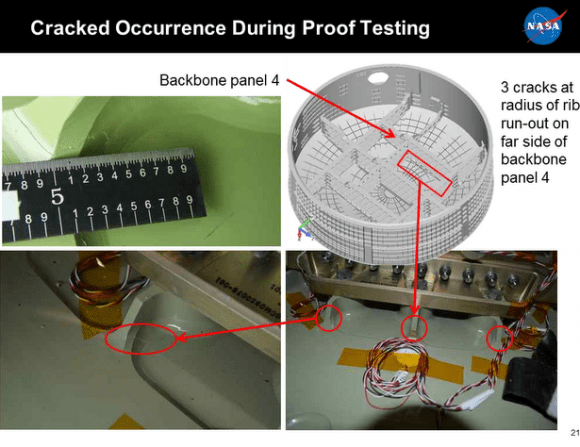

For the first time Orion looked to my eyes like a real spaceship, rather than the backbone shell outfitted with hundreds of important test harnesses, strain gauges and wiring to evaluate its physical and structural integrity.

Engineers and technicians at KSC have removed the initial pressure testing gear and are now installing all the flight systems and equipment – such as avionics, instrumentation, flight computers, thrusters, wiring, plumbing, heat shield and much more – required to transform the initial empty shell into a fully functioning spacecraft.

“The Orion skeleton was here before. Now we are putting in all of the other systems,” Schneider explained to me.

“We are really busy.”

“So far over 66,000 Orion parts have been shipped to KSC from over 40 US states,” Price explained.

The heat shield was due to arrive soon and technicians were drilling its attachment ring holes as I observed the work in progress.

“The propulsion, environmental control and life support systems are now about 90% in. The ammonia and propylene glycol loops for the thermal control system are in. Many of the flight harnesses are installed.”

“All of the reaction control thrusters are in – fueled by hydrazine – as well as the two hydrazine tanks and a helium tank. Altogether there are 12 hydrazine pods with two thrusters each,” Schneider elaborated.

The power distribution unit (PDU) – which basically functions as Orion’s computer brains – was installed just prior to my visit. All four PDU’s – which issue commands to the vehicle – were built by Honeywell.

Technicians were actively installing fiber optic and coaxial cables as I watched. They also were conducting leak tests on the environmental control coolant (ECLS) systems which had to be completed before the ‘power on’ testing could begin – in order to cool the avionics systems.

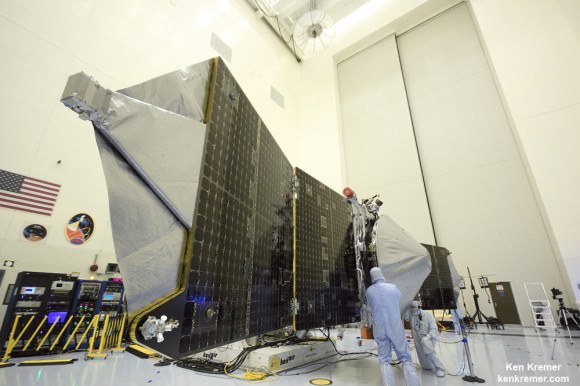

Thermal protection system (TPS) tiles were being bonded to the back panels which ring Orion. The TPS panels get attached early in 2014.

“This is real stuff,” said Schneider gleefully.

NASA says that “the preliminary data indicate Orion’s vehicle management computer, as well as its innovative power and data distribution system — which use state-of-the-art networking capabilities — performed as expected” during the initial crew module power on.

About two months or so of power on functional testing of various systems will follow.

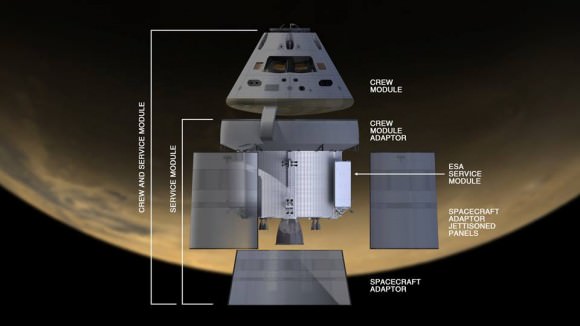

Just like the configuration used in the Apollo era, the Orion crew module will sit atop a service module – and that work is likewise moving along at a rapid clip.

“The Orion service module (SM) is also almost complete,” Schneider said as he showed me the service module structure.

“Structurally the SM is 90% done. The active thermal control system is in and all the fluid systems are welded in and pressure tested.”

Orion EFT-1 will blastoff atop a mammoth United Launch Alliance Delta IV Heavy rocket – the most powerful booster in America’s arsenal since the shuttle’s retirement in 2011.

The crew module and service module (CM/SM) will be mated inside the O&C and then be placed onto a mission adapter that eventually attaches to the top of the Delta IV Heavy booster.

They will be mated at the exact same spot in the O&C Building where the Apollo era command and service modules were stacked four decades ago.

Currently, the schedule calls for the Orion CM/SM stack to roll out to Kennedy’s Payload Hazardous Services Facility (PHSF) for servicing and fueling late this year, said Larry Price.

After that the CM/SM stack is transported to the nearby Launch Abort System Facility (LASF) for mating to the emergency Launch Abort System (LAS).

All that work could be done around March 2014 so that ground operations preparing for launch can commence, according to Price.

“In March 2014 we’ll be ready for ground ops. The normal launch processing flow starts in June 2014 leading to Orion’s launch from pad 37 in September 2014.”

“It’s very exciting and a tribute to the NASA and contractor teams,” Price said.

The 2014 uncrewed flight will be loaded with a wide variety of instruments to evaluate how the spacecraft behaves during launch, in space and then through the searing heat of reentry.

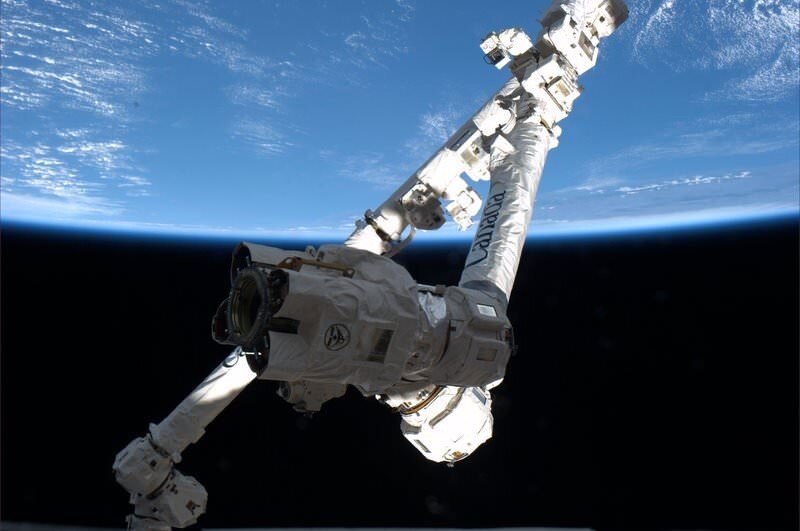

The two-orbit, four- hour flight will lift the Orion spacecraft and its attached second stage to an orbital altitude of 3,600 miles, about 15 times higher than the International Space Station (ISS) – and farther than any human spacecraft has journeyed in 40 years.

Although the mission will only last a few hours it will be high enough to send the vehicle plunging back into the atmosphere and a Pacific Ocean splashdown to test the craft and its heat shield at deep-space reentry speeds of 20,000 mph and endure temperatures of 4,000 degrees Fahrenheit – like those of the Apollo moon landing missions.

The EFT-1 mission will provide engineers with critical data about Orion’s heat shield, flight systems and capabilities to validate designs of the spacecraft, inform design decisions, validate existing computer models and guide new approaches to space systems development. All these measurements will aid in reducing the risks and costs of subsequent Orion flights before it begins carrying humans to new destinations in the solar system.

“The Orion hardware and the Delta IV Heavy booster for the EFT-1 launch are on target for launch in 2014,” Scott Wilson, NASA’s Orion Manager of Production Operations, told Universe Today in an interview.

…………….

Learn more about Orion, MAVEN, Mars rovers and more at Ken’s upcoming presentations

Nov 14-19: “MAVEN Mars Launch and Curiosity Explores Mars, Orion and NASA’s Future”, Kennedy Space Center Quality Inn, Titusville, FL, 8 PM

Dec 11: “Curiosity, MAVEN and the Search for Life on Mars”, “LADEE & Antares ISS Launches from Virginia”, Rittenhouse Astronomical Society, Franklin Institute, Phila, PA, 8 PM