The fifth mirror for the Giant Magellan Telescope (GMT) is now being cast, according to an announcement from the Giant Magellan Telescope Organization (GMTO), the body behind the project. The GMT is a ground-breaking segmented telescope consisting of 7 gigantic mirrors, and is being built at the Las Campanas Observatory, in Atacama, Chile.

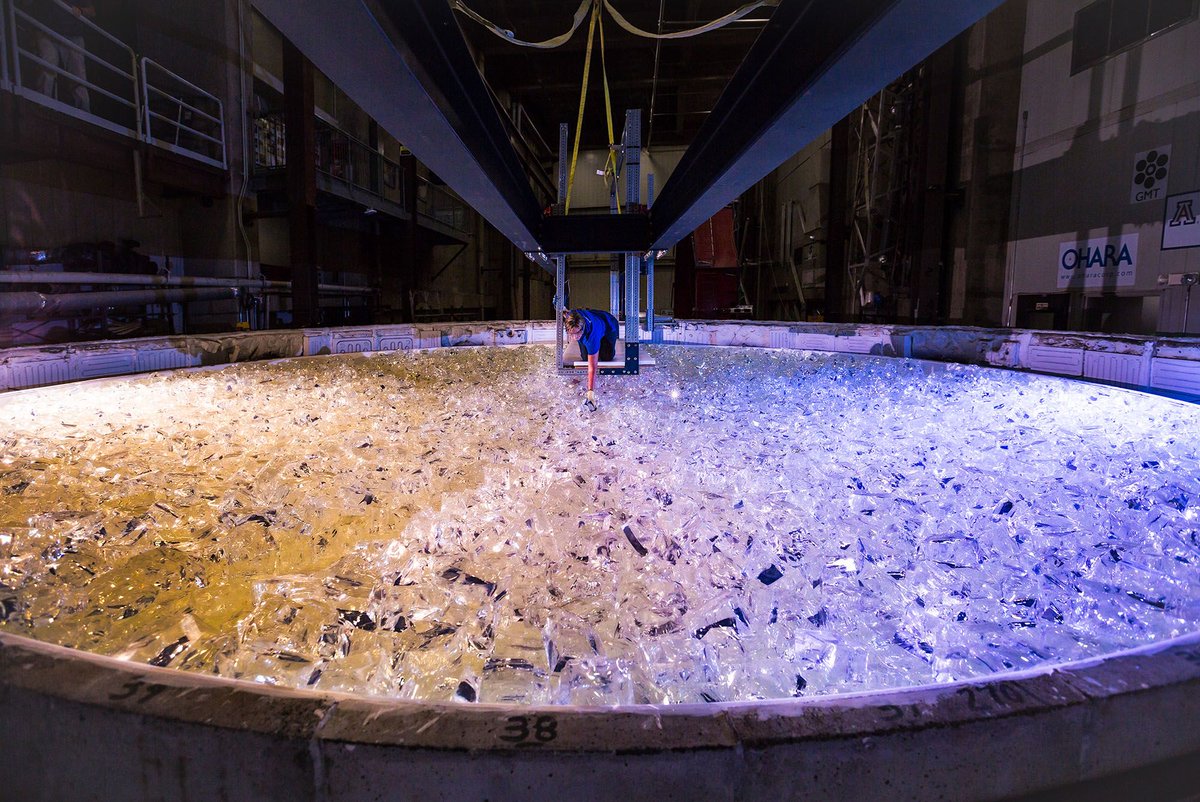

The mirrors for the GMT are being cast at the Richard F. Caris Mirror Laboratory, at the University of Arizona. This lab is the world centre when it comes to building large mirrors for telescopes. But in a lab known for ground-breaking, precision manufacturing, the GMT’s mirrors are pushing the engineering to its limits.

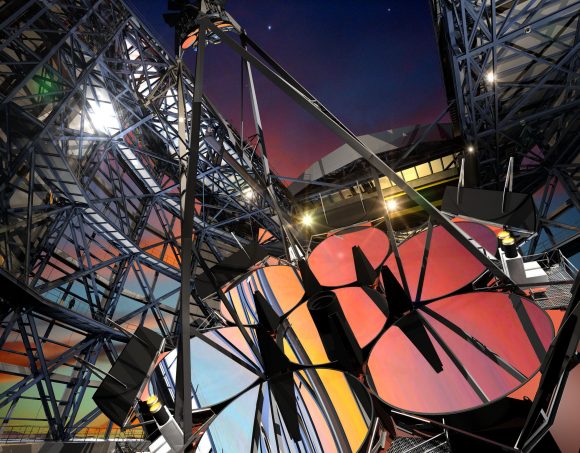

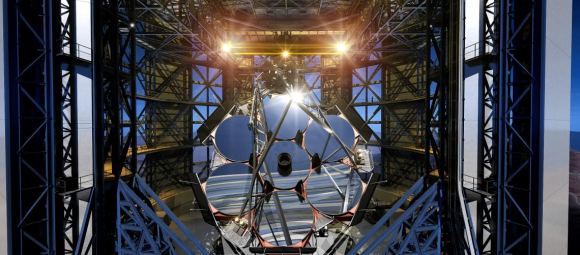

Seven separate mirrors, each the same size (8.4 meters,) will make up the GMT’s primary mirror. One mirror will be in the centre, and six will be arranged in a circle around it. Each one of these mirrors is a 20 ton glass behemoth, and each one is cast separately. Once the seven are manufactured (and one extra, just in case) they will be assembled at the observatory site.

The result will be an optical, light-gathering surface almost 24.5 meters (80 ft.) in diameter. That is an enormous telescope, and it’s taking extremely precise engineering and manufacturing to build these mirrors.

The glass for the mirrors is custom-manufactured, low-expansion glass from Japan. This glass comes as blocks, and each mirror requires exactly 17,481 kg of these glass blocks. A custom built furnace and mold heats the glass to 1165°C (2129°F) for several hours. The glass liquefies and flows into the mold. During this time, the mold is rotated at up to 5 rpm. Then the rotation is slowed, and for several months the glass cools in the mold.

After lengthy cooling, the glass can be polished. The tolerances for the mirrors, and the final shape they must take, requires very careful, extremely accurate polishing. The first mirror was cast in 2005, and in 2011 it was still being polished.

The mirrors for the GMT are not flat; they’re described as “potato chips.” They’re aspherical and parabaloidal. They have to be surface polished to an accuracy of 25 nanometers, which is a fraction of the wavelength of light.

“Casting the mirrors for the Giant Magellan Telescope is a huge undertaking, and we are very proud of the UA’s leading role creating this new resource for scientific discovery. The GMT partnership and Caris Mirror Lab are outstanding examples of how we can tackle complex challenges with innovative solutions,” said UA President Robert C. Robbins. “The University of Arizona has such an amazing tradition of excellence in space exploration, and I have been constantly impressed by the things our faculty, staff, and students in astronomy and space sciences can accomplish.”

Mirror construction for the GMT is a multi-stage process. The first mirror was completed several years ago and is in storage. Three others are in various stages of grinding and polishing. The glass for mirror 6 is in storage awaiting casting, and the glass for mirror 7 is on order from Japan.

Once completed, the GMT will be situated in Atacama, at the Las Campanas Observatory, where high-elevation and clear skies make for excellent seeing conditions. First light is planned for the mid 2020’s.

The GMT will be largest telescope in existence, at least until the Thirty Meter Telescope and the European Extremely Large Telescope supersede it.

“Creating the largest telescope in history is a monumental endeavor, and the GMT will be among the largest privately-funded scientific initiatives to date,” said Taft Armandroff, Professor of Astronomy and Director of the McDonald Observatory at The University of Texas at Austin, and Vice-Chair of the GMTO Corporation Board of Directors. “With this next milestone, and with the leadership, technical, financial and scientific prowess of the members of the GMTO partnership, we continue on the path to the completion of this great observatory.”

The power of the GMT will allow it to directly image extra-solar planets. That alone is enough to get anyone excited. But the GMT will also study things like the formation of stars, planets, and disks; the assembly and evolution of galaxies; fundamental physics; and first light and re-ionization.

The Giant Magellan Telescope is one of the world’s Super Telescopes that we covered in this series of articles. The Super Telescopes include the:

- Giant Magellan Telescope

- James Webb Space Telescope

- Thirty Meter Telescope

- European Extremely Large Telescope

- Large Synoptic Survey Telescope

- Wide Field Infrared Survey Telescope

You can also watch our videos on the Super Telescopes: Part 1: Ground Telescopes, and Part 2: Space Telescopes.

Evan,

THIS is what all our international resources should be focused on. None of the bs; selfish, greedy, short-term crap modern humans obsess.

I’m so proud of the ESO and their key nations and wish with all my might “we” (the US) had the same commitment, dedication and vision to lead such projects into the 21st century and beyond.

We should all support Chile as host to bolster their own infrastructure to continue creating such windows on our universe.

Anyway, maybe it’s just me.

Cheers, and thanks for your work!

Lee

(Joseph Lee Roy Gordon, Jr.)

I couldn’t help noticing in the photo of the man putting the glass into the mood, he is wearing mask and gloves but it looks like his hair is uncovered… Curious if hairs falling into the glass would make a difference.. I guess it all polished down somehow…

^ mood = mold. time to disable autocorrect

Having spent some time at the facility underneath the stadium in Tucson at the University, I can tell you a few hairs in the kiln/mold are quickly destroyed once the glass becomes molten. It takes some time for the temp to be reached, and they bring in special, huge truck-mounted generators to supply the massive current needed to melt all this glass. The glass is Ohara glass and comes in boxes of big chunks. I have several form the Large Binocular telescope I use as cool paperweights!