Boeing unveiled full scale mockup of their commercial CST-100 ‘Space Taxi’ on June 9, 2014 at its intended manufacturing facility at the Kennedy Space Center in Florida. The private vehicle will launch US astronauts to low Earth orbit and the ISS from US soil.

Credit: Ken Kremer – kenkremer.com

Story updated[/caption]

KENNEDY SPACE CENTER, FL – Boeing unveiled a full scale mockup of their CST-100 commercial ‘space taxi’ on Monday, June 9, at the new home of its future manufacturing site at the Kennedy Space Center located inside a refurbished facility that most recently was used to prepare NASA’s space shuttle orbiters for missions to the International Space Station (ISS).

The overriding goal is restart our country’s capability to reliably launch Americans to space from US territory as rapidly and efficiently as possible.

The CST-100 crew transporter was revealed at an invitation only ceremony and media event held on Monday, June 9, inside the gleaming white and completely renovated NASA processing hangar known as Orbiter Processing Facility-3 (OPF-3) – and attended by Universe Today.

The huge 64,000 square foot facility has sat dormant since the shuttles were retired following their final flight in July 2011 and which was commanded by Chris Ferguson, who now serves as director of Boeing’s Crew and Mission Operations.

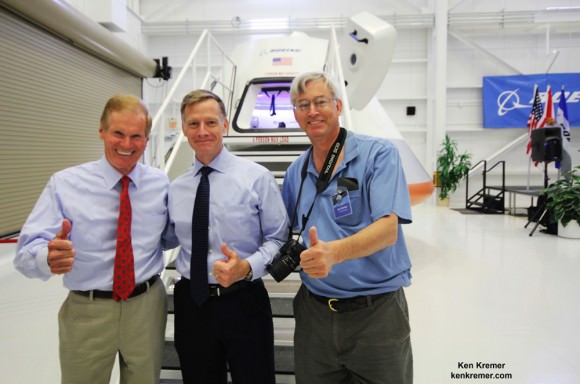

Universe Today was invited to be on location at KSC for the big reveal ceremony headlining US Senator Bill Nelson (FL) and Boeing executives including shuttle commander Ferguson, for a first hand personal inspection of the private spaceship and also to crawl inside and sit in the seats of the capsule designed to carry American astronauts to the High Frontier as soon as 2017.

“Today we celebrate this commercial crew capsule,” said Sen. Nelson at the unveiling ceremony. “This vehicle is pretty fantastic and the push into space the CST-100 represents is historic.”

“We are at the dawn of a new Space Age. It’s complemented by the commercial activities going to and from the space station and then going outside low Earth orbit [with Orion], as we go to the ultimate goal of going to Mars. There is a bright future ahead.”

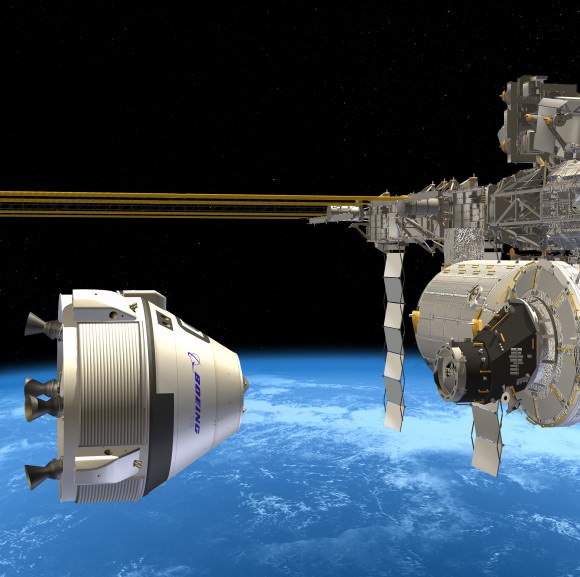

The purpose of developing and building the private CST-100 human rated capsule is to restore America’s capability to ferry astronauts to low-Earth orbit and the space station from American soil aboard American rockets, and thereby end our total dependency on the Russian Soyuz capsule for tickets to space and back.

Boeing’s philosophy is to make the CST-100 a commercial endeavor, as simple and cost effective as possible in order to quickly kick start US human spaceflight efforts. It’s based on proven technologies drawing on Boeing’s 100 year heritage in aviation and space.

“The CST-100, it’s a simple ride up to and back from space,” Ferguson told me. “So it doesn’t need to be luxurious. It’s an ascent and reentry vehicle – and that’s all!”

So the CST-100 is basically a taxi up and a taxi down from LEO. NASA’s complementary human space flight program involving the Orion crew vehicle is designed for deep space exploration.

Read my exclusive, in depth one-on-one interviews with Chris Ferguson – America’s last shuttle commander – about the CST-100; here and here.

The stairway to America’s future human access to space is at last literally taking shape from coast to coast.

Sen. Nelson, a strong space exploration advocate for NASA and who also flew on a space shuttle mission on Columbia back in January 1986, was the first person to climb the steps and enter the hatch leading to Boeing’s stairway to the heavens.

“This is harder to get in than the shuttle. But the seats are comfortable,” Nelson told me as he climbed inside the capsule and maneuvered his way into the center co-pilots seat.

Nelson received a personal guided tour of the CST-100 spaceship from Ferguson.

The capsule measures 4.56 meters (175 inches) in diameter.

The media including myself were also allowed to sit inside the capsule and given detailed briefings on Boeing ambitious plans for building a simple and cost effective astronaut transporter.

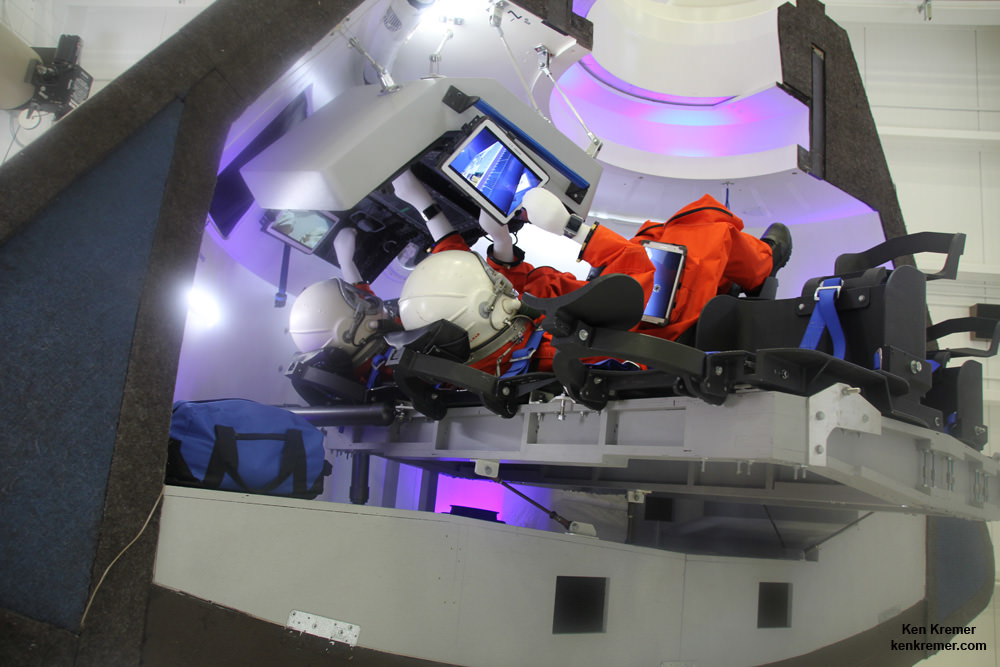

The vehicle includes five recliner seats, a hatch and windows, the pilots control console with several attached Samsung tablets for crew interfaces with wireless internet, a docking port to the ISS and ample space for 220 kilograms of cargo storage of an array of equipment, gear and science experiments depending on NASA’s allotment choices.

The interior features Boeing’s LED Sky Lighting with an adjustable blue hue based on its 787 Dreamliner airplanes to enhance the ambience for the crew.

Boeing is among a trio of American aerospace firms, including SpaceX and Sierra Nevada Corp, vying for the next round of contracts to build America’s ‘space taxi’ in a public/private partnership with NASA using seed money under the auspices of the agency’s Commercial Crew Program (CCP).

Since 2010, NASA has spent over $1.5 billion on the commercial crew effort.

Boeing has received approximately $600 million and is on target to complete all of NASA’s assigned CCP milestones in the current contract phase known as Commercial Crew Integrated Capability initiative (CCiCAP) by mid-2014.

Boeing’s CST-100 crew capsule reveal on June 9 comes just two weeks after SpaceX CEO Elon Musk’s Hollywoodesqe glitzy live show on May 29 – pulling the curtain off his firms ‘Dragon’ crew vehicle entry into NASA’s commercial crew program.

NASA officials say that the next round of contracts aims at building a human rated flight vehicle to dock at the ISS by late 2017.

The next contract phase known as Commercial Crew Transportation Capability (CCtCap) will result in one or more awards by NASA later this summer around August or September .

Sen. Nelson expressed his hope that the competition will continue since Congress appears likely to finally approve something near the President’s CCP funding request of over $800 million in the Fiscal 2015 NASA budget.

“With about $800 million, that’s enough money for NASA to do the competition for at least two and maybe more,” said Nelson. “That of course is up to NASA as they evaluate all the proposals.”

NASA had hoped to fly the first commercial crew missions in mid-2015.

But repeated CCP funding cuts by Congress since its inception in 2010 has already caused significant delays to the start of the space taxi missions for all three companies contending for NASA’s commercial crew contracts.

In fact the schedule has slipped already 18 months to the right compared to NASA’s initial plans thus forcing the agency to buy more Soyuz seats from the Russians at a cost of over $70 million each.

The reusable capsule will launch atop a man rated United Launch Alliance (ULA) Atlas V rocket.

It was glorious to be seated inside America’s next spaceship destined to carry humans.

The next generation of US human spaceflight is finally coming to fruition after a long down time.

Read my exclusive new interview with NASA Administrator Charles Bolden explaining the importance of getting Commercial Crew online to expand our reach into space- here.

Stay tuned here for Ken’s continuing Boeing, SpaceX, Orbital Sciences, commercial space, Orion, Curiosity, Mars rover, MAVEN, MOM and more planetary and human spaceflight news.