The imminent impact of the already deadly Category 4 Hurricane Matthew along the Florida Space Coast tonight, Thursday, October 6, has forced the closure of NASA’s Kennedy Space Center (KSC) and mass evacuations along the US East coast from Florida, to Georgia to the Carolinas.

“Hurricane Matthew, currently an extremely dangerous Category 4 storm on the Saffir-Simpson Hurricane Wind Scale, continues to bear down on the southeastern United States,” says NASA in an update today.

NASA has closed KSC for today and tomorrow, at a minimum and the center has entered HurrCon 1 status.

“Under the current storm track, peak winds are forecast to be 125 mph sustained with gusts to 150 mph, however a shift in the track even slightly could improve the wind forecast somewhat,” wrote NASA’s Brian Dunbar.

“The Kennedy Space Center is closed today, Oct. 6, and Friday for Hurricane Matthew. Kennedy Space Center is now in HurrCon 1 status, meaning a hurricane is imminent.”

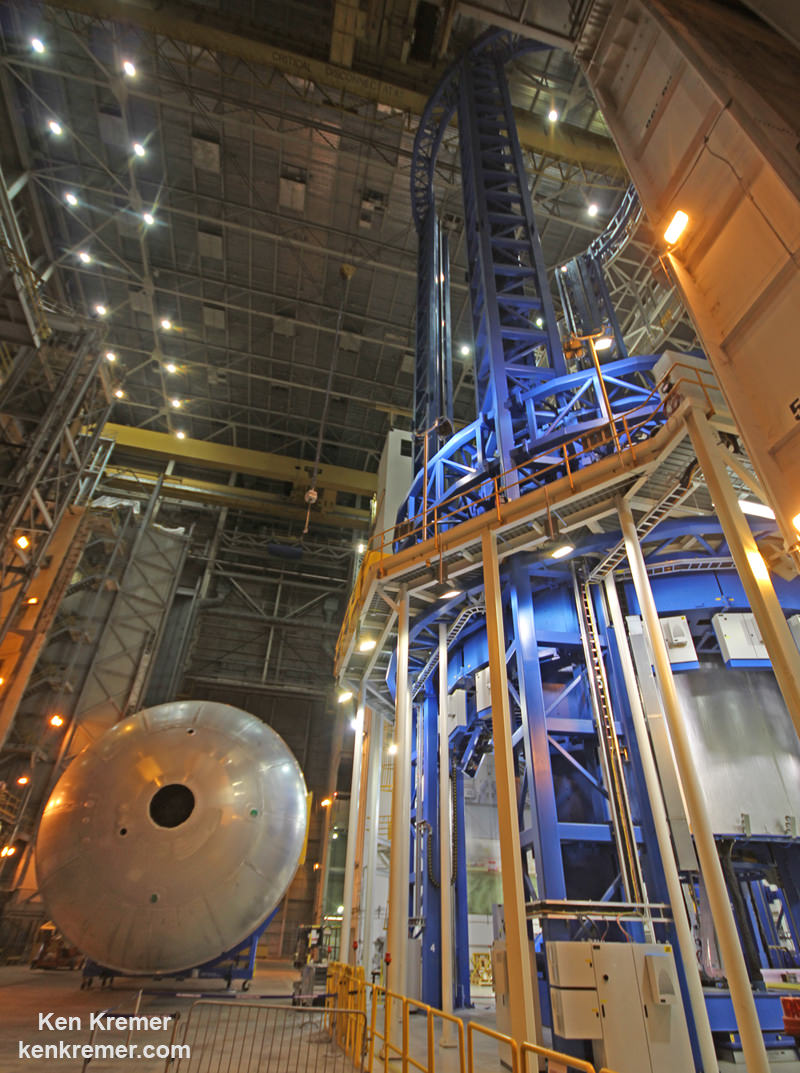

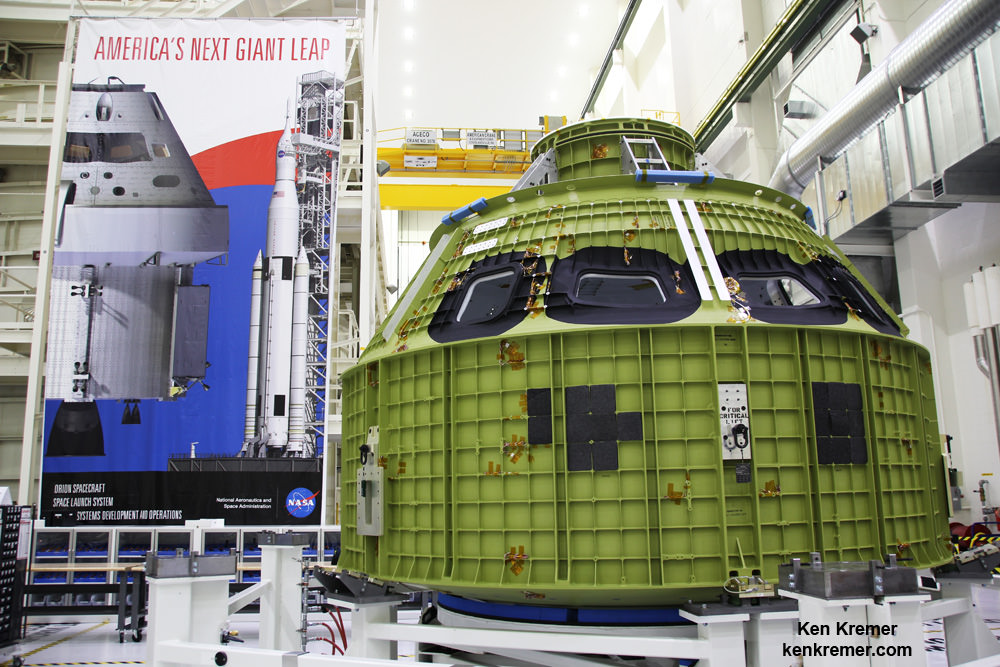

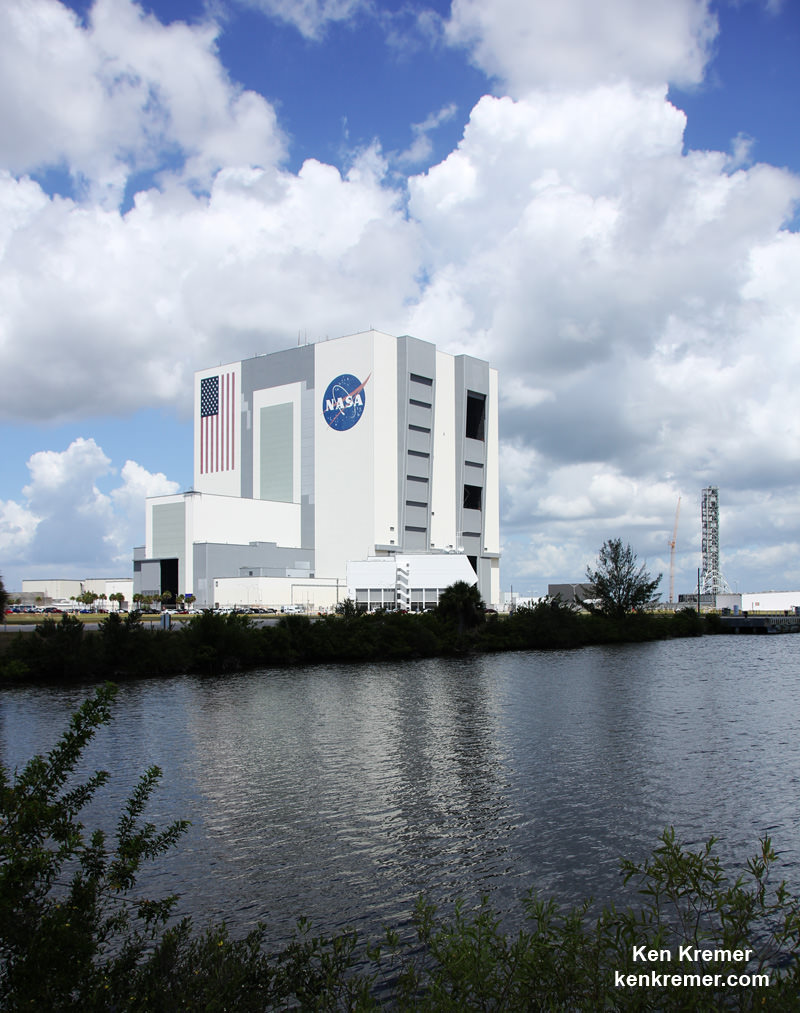

The Kennedy Space Center on Florida’s Space Coast is home to the iconic Vehicle Assembly Building (VAB) – the most well known building at NASA – as well as Launch Complex’s 39 A and B which launched American astronauts to Moon and thereafter Space Shuttles for three decades.

The launch pads sit precariously close to the Atlantic Ocean shoreline – just a few hundred yards (meters) away!

“Across the spaceport, essential personnel are preparing facilities for the storm’s arrival,” according to George Diller, NASA Kennedy Space Center Public Affairs Officer.

“Hurricane Matthew is expected to make its closest approach to the Cape Canaveral/Kennedy area overnight Thursday and into Friday morning, bringing with it the potential for heavy rain, storm surge and hurricane-force winds.”

The last time a major Hurricane impacted near KSC and the Space Coast was in 2004. The VAB suffered some outside damage.

The Kennedy Space Center Visitor Complex is also closed on Thursday, October 6 and Friday, October 7.

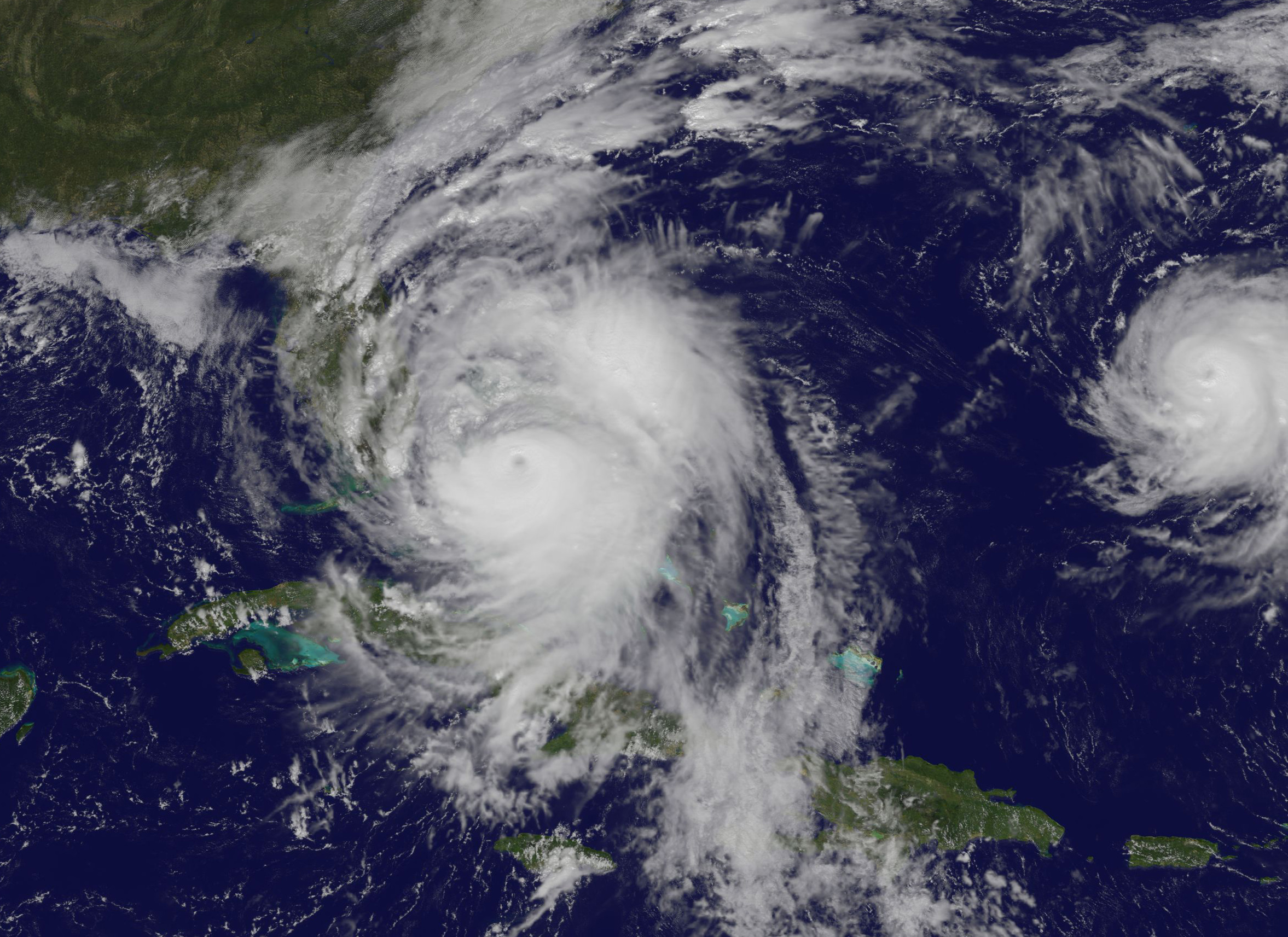

Hurricane Matthew is bearing down on the US East Coast right now at Florida’s Peninsula and is tracking north.

Herein is the latest satellite imagery from NASA and NOAA of this evening.

Mass evacuations have been ordered and States of Emergencies declared by the Governors of Florida, Georgia and North and South Carolina.

The high winds, storm surge of potentially 5 to 11 feet, drenching rains and extensive flooding is expected to cause massive damage and devastation to homes, businesses and infrastructure.

Hundreds of thousands of folks have left their home over the past 2 days. Many gas stations are dry and grocery store shelves emptied.

Matthew will cause a wide swath of destruction and potentially deaths along hundreds of miles of US shoreline and inland areas as the massive storm hugs the coast like none before in recorded history.

Furthermore, hundreds of thousands of folks are expected to lose power as well, for days and perhaps weeks.

Hundreds of deaths and massive destruction in Haiti, Cuba and elsewhere in the Caribbean can already be blamed on Hurricane Matthew – a storm like none other and by far the worst since Superstorm Sandy and Hurricane Katrina.

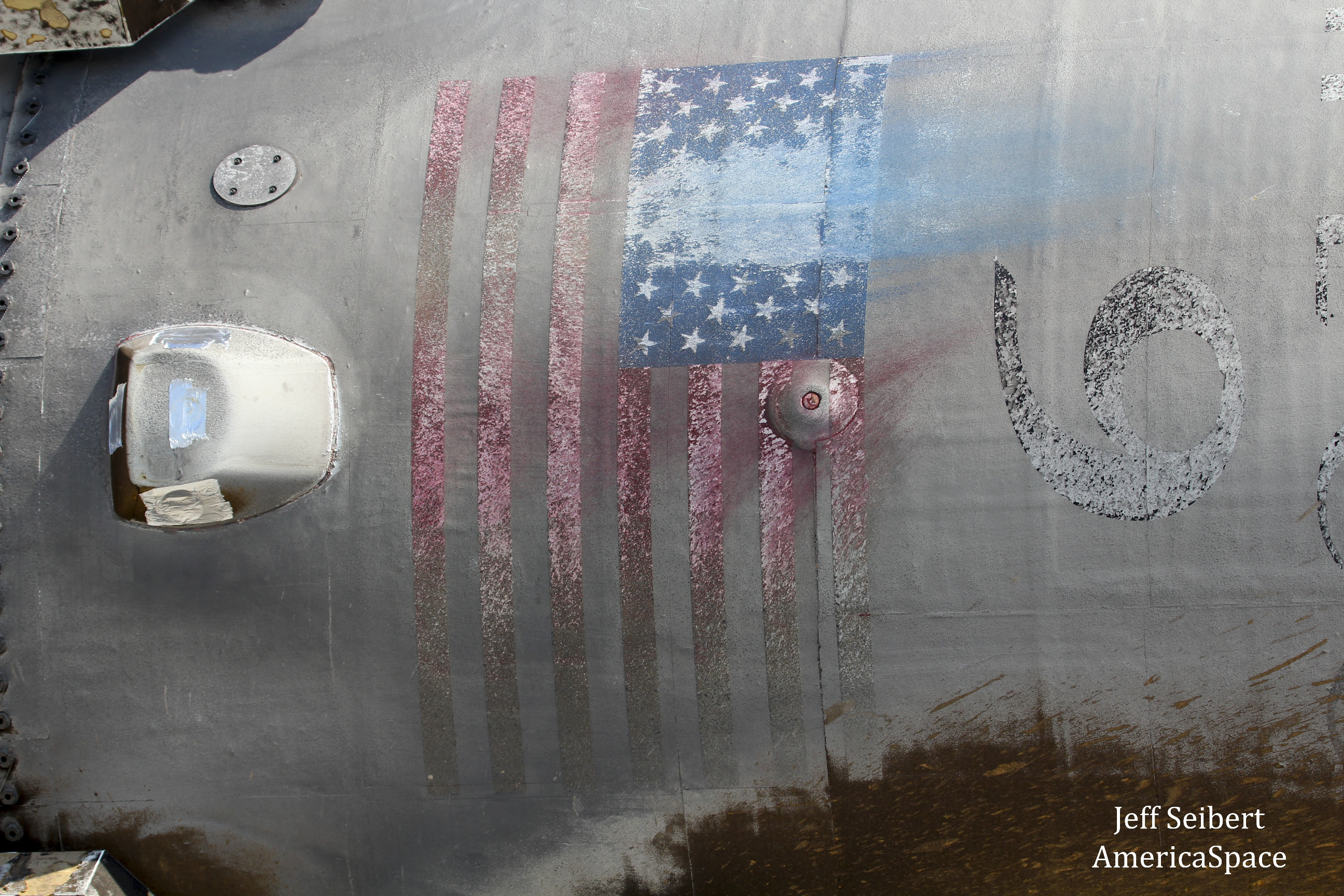

After the storm passes KSC will evaluate all its facilities.

“Once the storm has passed, center facilities and infrastructure will be assessed and employees will be cleared to return when it is safe to do so,” Diller.

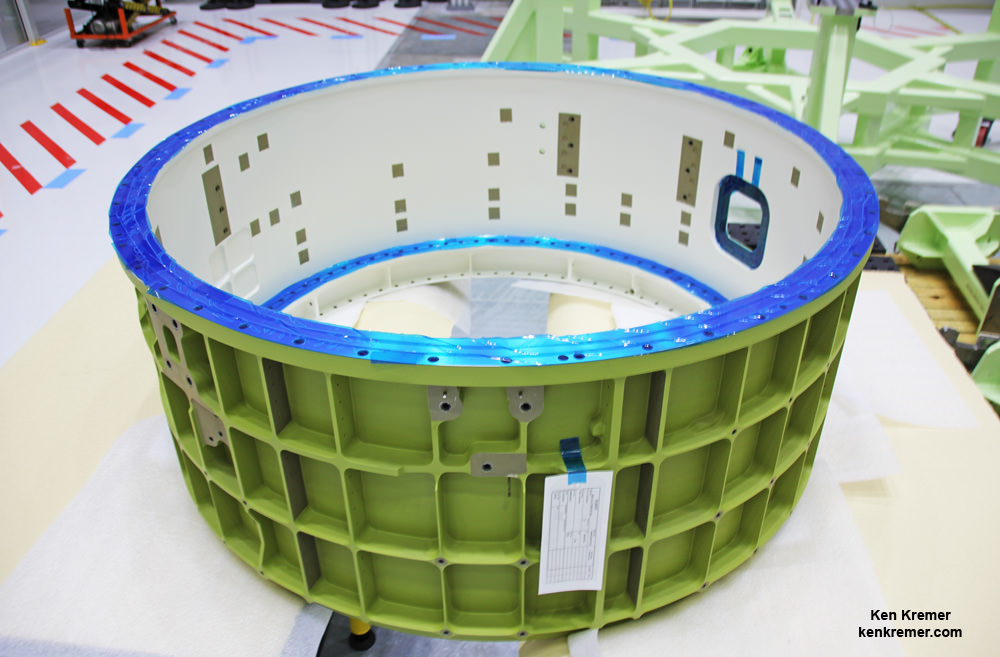

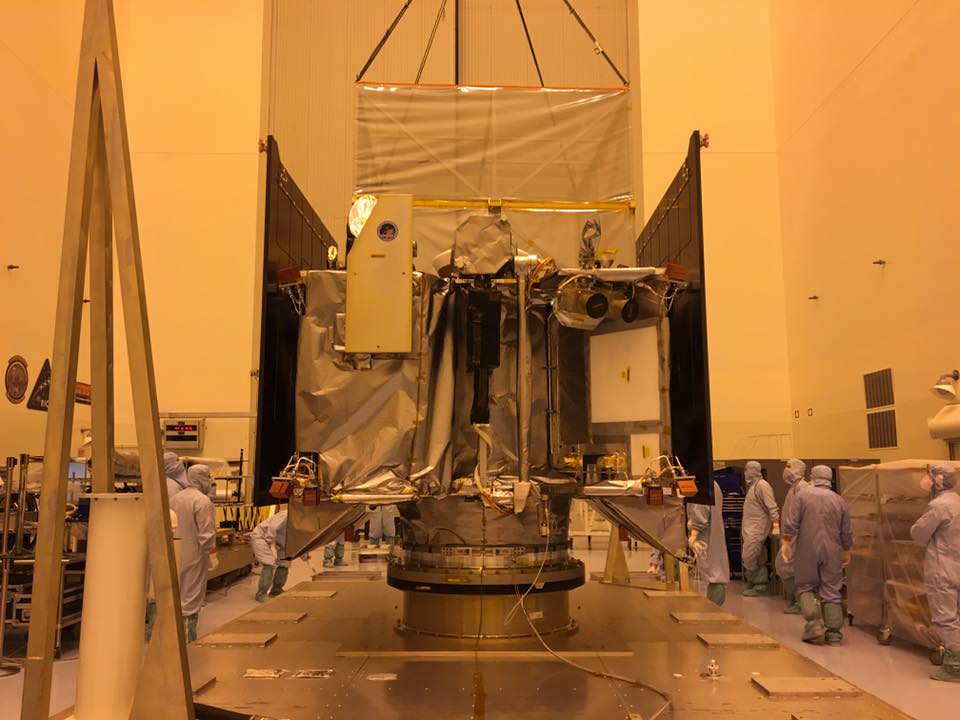

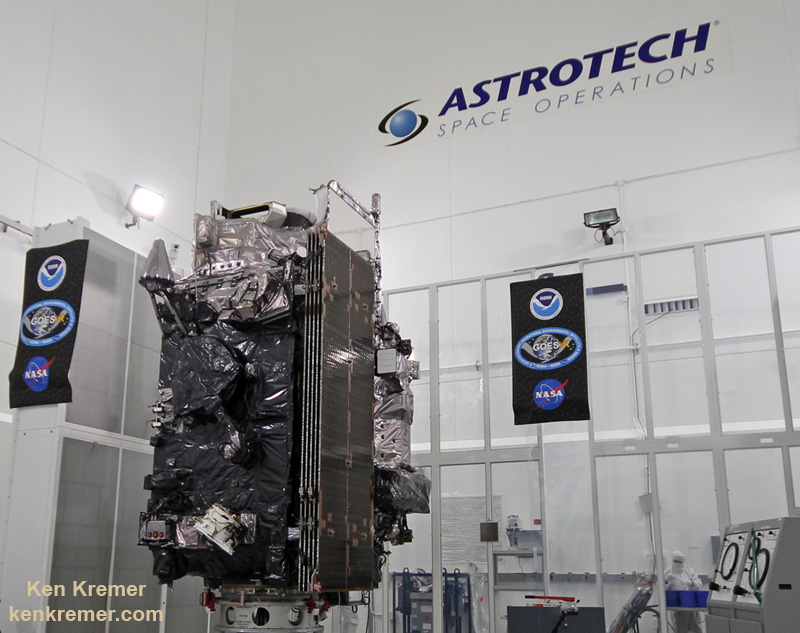

Indeed NASA was preparing to launch America’s newest and most advanced weather satellite on Nov 4. It’s named GOES-R and was slated for blastoff from Cape Canaveral Air Force Station atop a ULA Atlas V on Nov. 4.

The launch facilities will have to be thoroughly inspected before the launch can proceed.

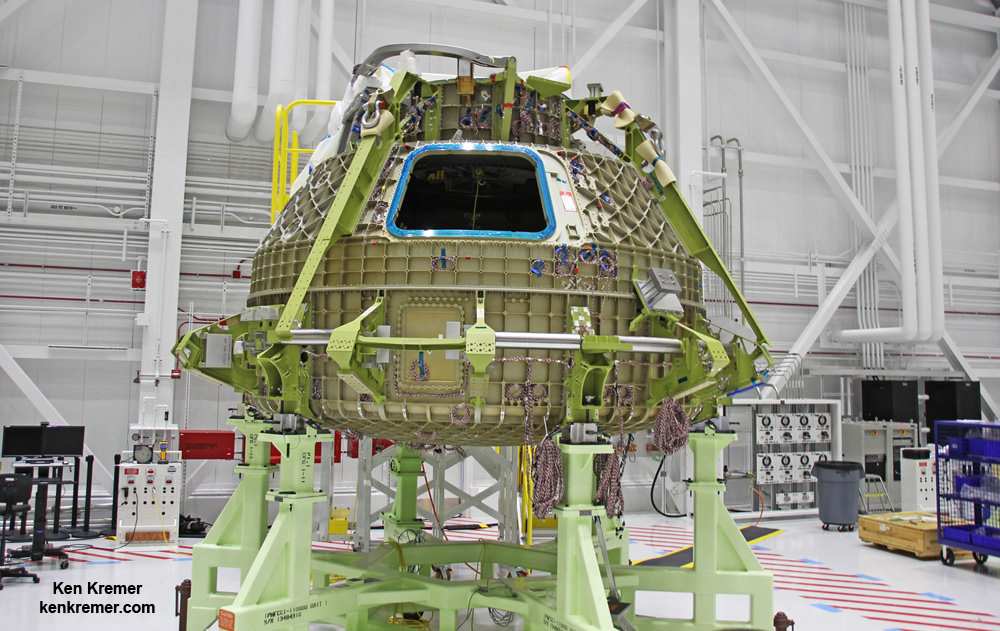

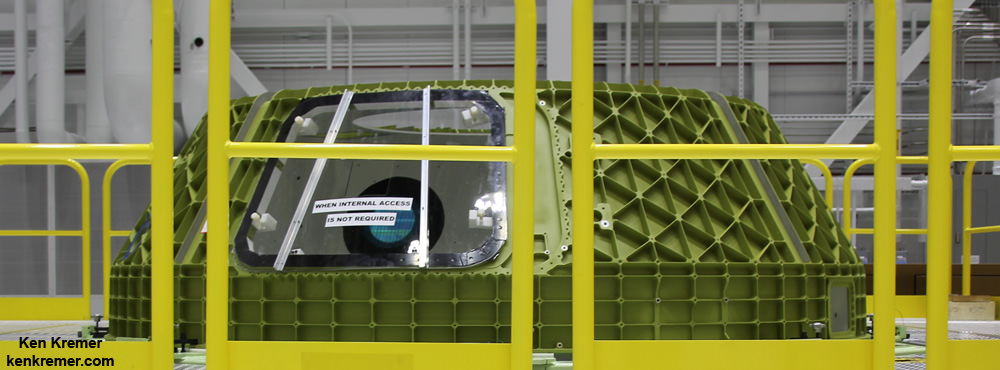

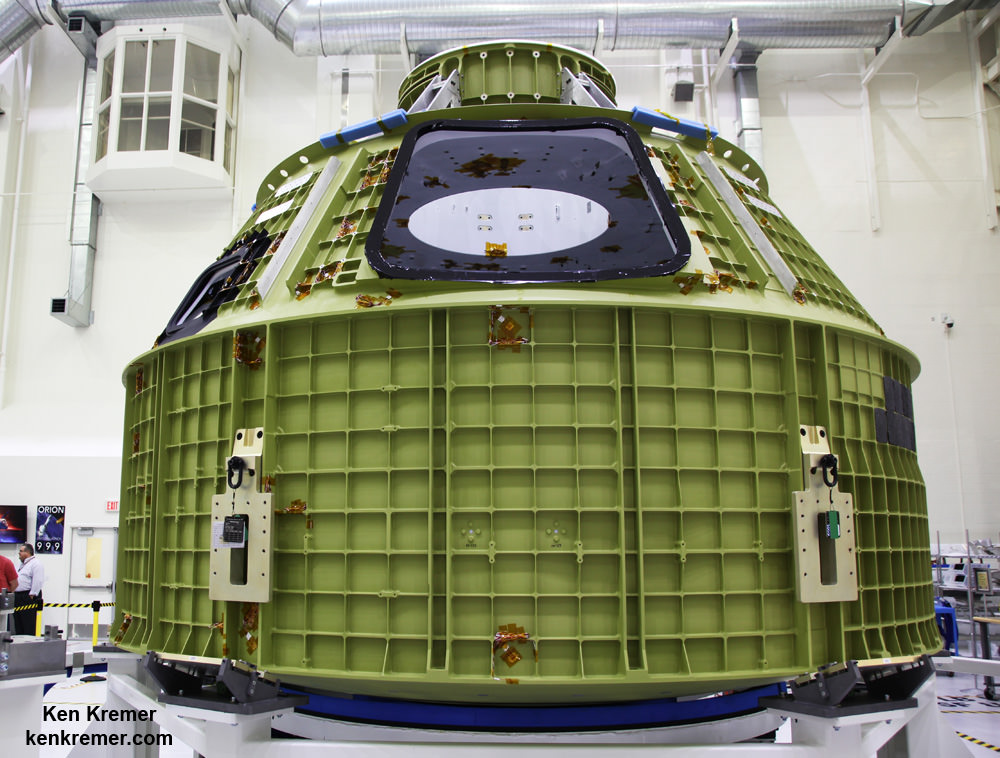

The satellite is in the final stages of preparation at the Astrotech Space Operations Facility in Titusville, FL as I recently observed during an up close visit in the High Bay cleanroom.

Titusville and Astrotech could suffer a direct hit from Matthew. But the satellite has been secured.

Here is the latest Advisory from the National Hurricane Center (NHC) as of 8 PM EDT Oct 6.

At 800 PM EDT (0000 UTC), the eye of Hurricane Matthew was located over the western end of Grand Bahama Island near latitude 26.6 North, longitude 78.9 West. The hurricane is moving toward the northwest near 13 mph (20 km/h), and this general motion is expected to continue tonight with a turn toward the north-northwest early Friday. On the forecast track, the eye of Matthew should move away from Grand Bahama Island during the next few hours, and move close to or over the east coast of the Florida peninsula through Friday night.

Reports from a NOAA Hurricane Hunter aircraft indicate that maximum sustained winds are now near 130 mph (210 km/h) with higher gusts. Matthew is a category 4 hurricane on the Saffir-Simpson Hurricane Wind Scale. Some fluctuations in intensity are likely while the hurricane moves toward the coast of Florida.

Hurricane-force winds extend outward up to 60 miles (95 km) from the center and tropical-storm-force winds extend outward up to 185 miles (295 km). Settlement Point in the Bahamas recently reported a sustained wind of 79 mph (128 km/h) with a gust of 105 mph (169 km/hr). The Lake Worth Pier near Palm Beach, Florida, recently reported a sustained wind of 46 mph (74 km/h) and a wind gust of 60 mph (96 km/h).

The minimum central pressure estimated from NOAA Hurricane Hunter data is 939 mb (27.73 inches).

…….

The latest weather briefing indicates that “tropical storm force winds beginning at Cape Canaveral tonight at midnight with hurricane force winds starting at about 6 a.m.

A hurricane ride-out crew of 116 has arrived at KSC this evening to prepare for Matthew.

“All facilities at Kennedy Space Center and Cape Canaveral Air Force Station have been secured.”

SpaceX is currently renovating and refurbishing pad 39A to launch their commercial Falcon 9 and Falcon Heavy rockets as well the Crew Dragon with astronauts on mission to the ISS.

The eye of the storm is barreling towards KSC at this moment. Stay tuned for the outcome.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news.